REV

. 10

22-04-2020

INSTALLATION

,

USE AND MAINTENANCE MANUAL

–

PN

16 / 40

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

T

EL

. +39 0434 636811 F

AX

. +39 0434 636812

http://www.jurop.it

e-mail: [email protected]

preventing oxidation. When the detergent mix is finished, continue

running the pump at the lo west possible vacuum rate for a few

minutes, then close venting and suction valves up to 50-60%

maximum, for a couple of minutes. With this operation the pump will

dry from the heated air and protected from the chemical attack of

the detergent.

7.

Washing the pump with this detergent guarantees a protection after

some days of inoperativity. If the pump is not used for more than

two weeks, after having washed and dried the inner parts as

described above, it is recommended to suck slowly 200 cc anti-rust

and water-repellent protective oil (or, if not available, a very fluid

gear oil).

Attention: do not carry out also this operation on

very hot pumps (for example after a working day)

until they have cooled down.

In case the exhaust line cannot be disconnected,

drain the liquids accumulated in the separator of

the exhaust silencer.

• Do not convey the exceeding flow outlet towards the suction port.

• Control the air flow by adjusting the rotation speed: do not use the

safety relief valve to discharge the exceeding flow.

• Do not squeeze the hoses/pipes.

• If the decompressor operates in vacuum or under pressure with a

capacity environment (such as a cistern) and is configured in the “FL”

flanged version (without manifold with 4-way valve and non-return vale),

it is advisable to intercept the working line of the machine when it is

stopped, to prevent contrary rotations until the rebalancing of the

pressures. The interception can take place through a controlled valve or

an automatic unidirectional valve (swing valve).

• Avoid starting the pump under load: motor and drive system can be

excessively stressed.

6.1.

Ordinary maintenance

• Any interventions must be performed when the machine is cold, stopped and switched off.

• Installation and maintenance must be operated only by qualified personnel wearing the proper clothes and the necessary tools as well as

protection devices.

• Use suitable protection equipment (gloves, protection glasses, boots...)

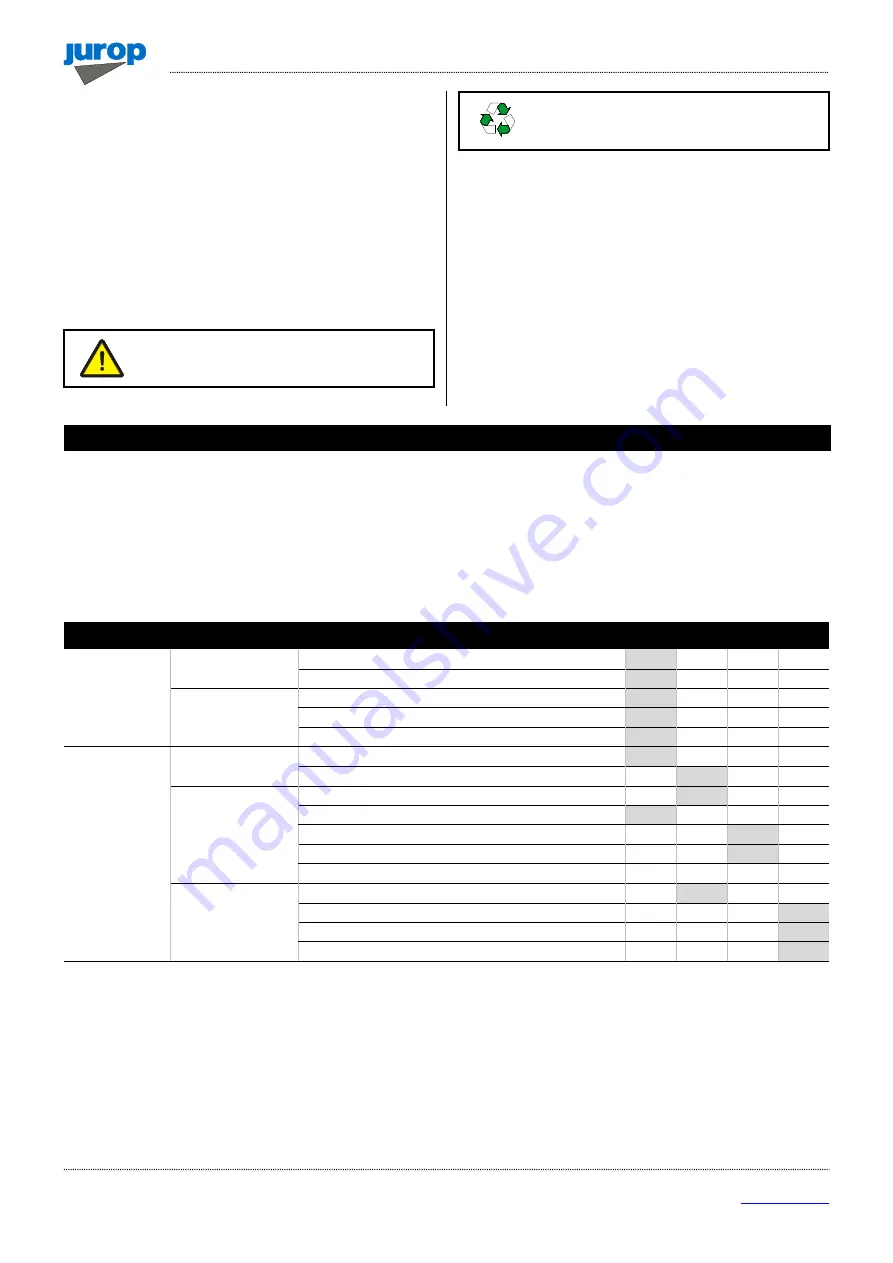

• In the following table summarizes the main controls to be performed and the frequency of intervention.

Operating

Condition

Maintenance Area

Check

8

H

50

H

500

H

1000H

OPERATING

Vacuum line

Check safety valve (non-return valve)

Operating pressure

Transmission / Pump

Lubrication: dripping into oilers

Rotation speed

Sound pressure level (also HDR motor)

STANDSTILL

Vacuum line

Suctions filters

4-way changeover valve: check and lubricate

Pump

Clean oilers glasses

Check oil level

Check vanes wear

Change oil (*)

Pump’s inner washing (**)

Overall

Greasing

Check cardan shaft drive

Chack transmission pulley

Swing valve wear check

(*) The first oil change must be done inside 500 hours operation. Following changes every 5000 hours or 12 months. In order to choose the most

suitable oil, see paragraph 2.5.

(**) After operation in dusty environments, after accidental sucking of liquids inside the pump or before a long inoperativity period it is

recommended to wash the pump inside according to the procedure described at paragraph 5.2.

6. Maintenance