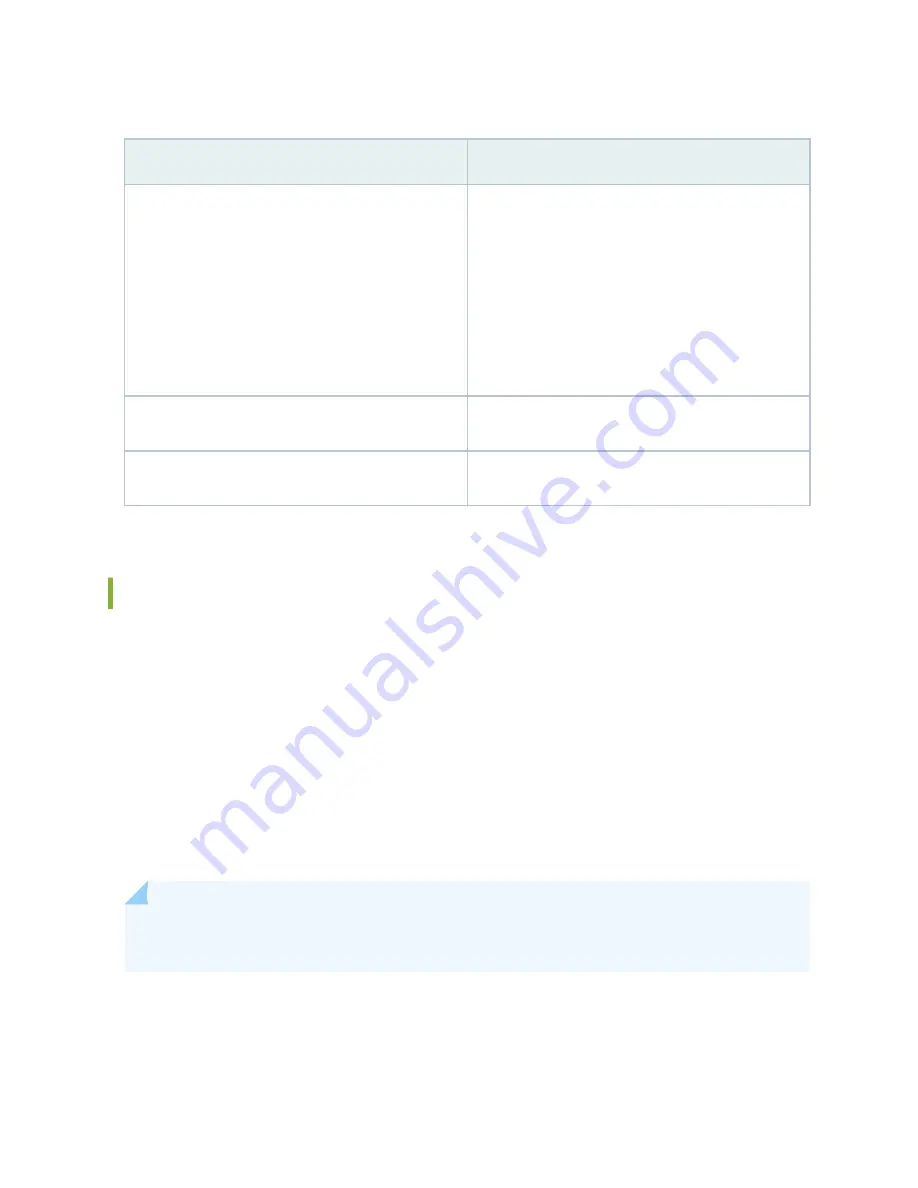

Table 11: Parts List for a Fully Configured SSR1200

(Continued)

Component

Quantity

Rack mount kit

Part number: SSR1200-RMK

•

2 front mounting brackets

•

2 side mounting rails

•

2 rear mounting blades

•

8 rack screws and cage nuts

•

14 M4 flat-head screws

RJ-45 to USB A serial cable

1

Documentation Roadmap

1

Install the SSR1200 in a Rack

You can install an SSR1200 appliance into a four-post rack or a cabinet.

Complete these prerequisites before you install the appliance:

• Prepare the site for installation as described in

"Site Preparation Checklist for SSR1200" on page 15

• Be sure the site has adequate clearance for both airflow and hardware maintenance, as described in

"SSR1200 Site Guidelines and Requirements" on page 16

• Unpack the appliance as described in

"Unpack an SSR1200" on page 25

.

Ensure that you have Phillips (+) screwdriver, number 2.

NOTE: Installing the chassis in a rack requires two people: one person lifts the chassis while the

other secures it to the rack.

27