11

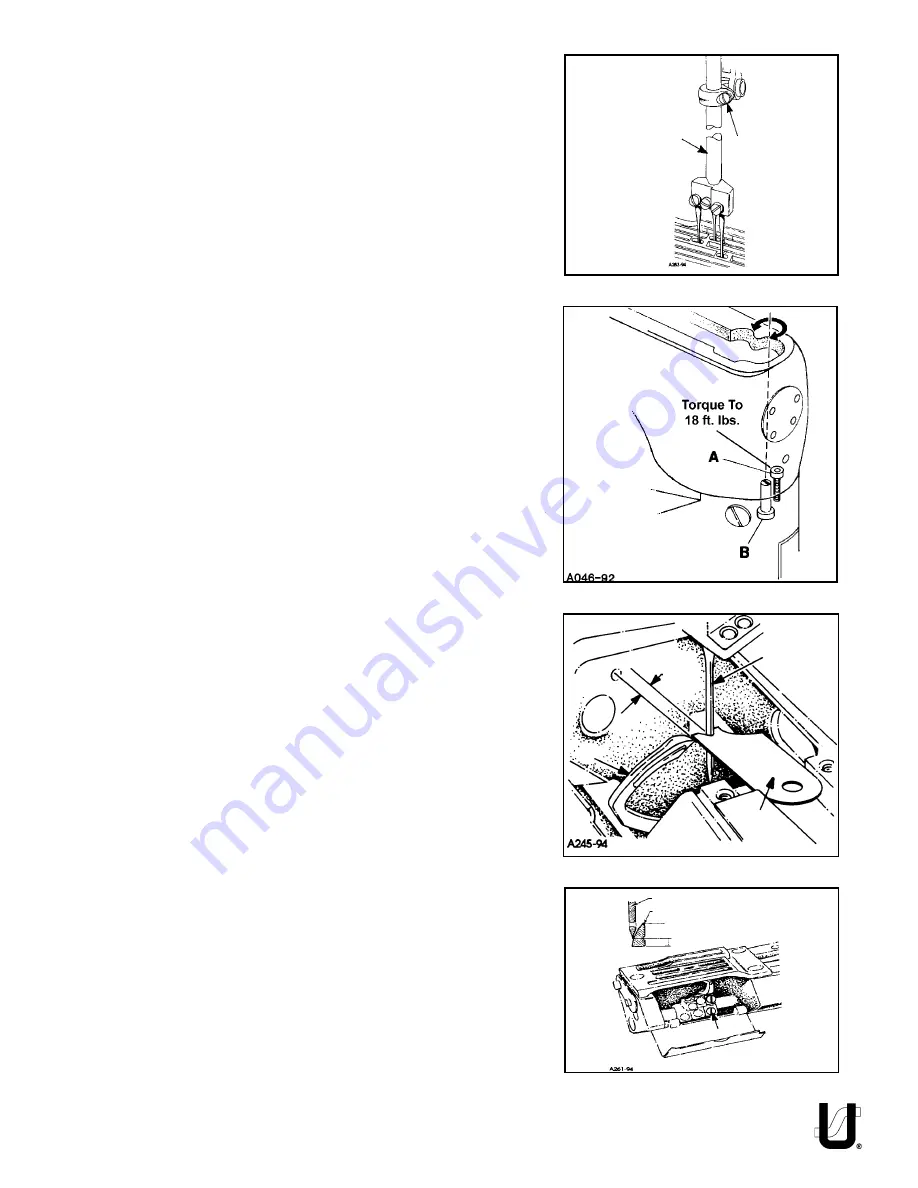

TIGHTENING NEEDLE HEAD

When replacement of the needle bar, and or needle head is neces-

sary, torque the needle head to needle bar 14-16 in. lbs. (1.6-1.8Nm)

or use torque rod No. 21227AR that has been supplied with the

machine, for the purpose of eliminating the possibility of distorting

the needle bar due to overtightening. Insert the torque rod in the

hole at the upper end of the needle bar, while holding the needle

bar head with a suitable tool, turn the needle bar with the torque rod

onto the needle bar head. When the rod starts to bend, the needle

bar head has been threaded into the needle bar properly.

ALIGNING NEEDLES IN THROAT PLATE SLOTS

Insert a new set of needles, type and size specified, with screw (B, Fig.

4) slightly loosened, lower needle bar (A) and turn needle head as

required until the needles are centered in the throat plate needle

hole slots. Tighten screw (B) torque to 19-21in.lbs. (2.1-2.4Nm).

NOTE:

If the needles can not be aligned in the throat plate slots, the

lower cylinder must be moved as stated below.

CENTERING THE CYLINDER

Remove the top front cover and gasket from the main frame. Loosen

cylinder holding screw (A, Fig. 5). Turn eccentric screw (B) clockwise

or counterclockwise to move the cylinder so the needles are

centered in the needle holes. Tighten screws (A) torque to 18 ft.lbs.

and recheck settings.

NOTE:

The cylinder may not move freely when the eccentric is

turned because the joint sealant compound has set.

SETTING THE LOOPER

Insert a new set of needles, type and size specified. Always adjust the

looper (A, Fig. 6) for the left needle first. Set the looper so that the

distance from the center of the needle (B) to the point of the looper

(A) is 9/64" (3.6mm) when the looper is at its farthest position to the

left. Looper gauge (C) No. 21225-9/64 can be used advantageously

in making this adjustment. If adjustment is required, loosen screw (A,

Fig. 7) in looper holder, permitting movement in either direction to

attain the 9/64" (3.6mm) dimension as shown in Fig. 6. Retighten

screw (A, Fig. 7). Repeat for other needles and loopers.

Rotate handwheel in operating direction to assure that the looper

point passes to the rear of the needle to touch but not deflect. This

adjustment can be made by loosening screw (A, Fig. 7) in looper

holder. Looper holder can be moved front to back to attain looper

to needle setting. Always check the 9/64" (3.6mm) looper gauge

setting after setting the looper to the back of the needle, and

conversely, always check the setting of the looper to the back of the

needle after setting the 9/64" (3.6mm) looper gauge.

The amount of looper avoid has been set at the factory to .110"

(2.8mm). If it becomes necessary to adjust the amount of avoid it is

recomended as a starting point, to have the points of the decending

needles contact the back of the lower 1/3 of the back of the

looper blade.

A

FIG. 4

Descending Needles

Looper Blade

Lower 1/3

FIG. 7

A

B

9/64"

(3.6mm)

C

B

FIG. 5

FIG. 6

A

Summary of Contents for UnionSpecial 35800DLU

Page 7: ...7 THREADING OILING FOR PLAIN FEED FIG 1A...

Page 8: ...8 THREADING OILING FOR DIFFERENTIAL FEED FIG 1B...

Page 18: ...18...

Page 20: ...20...

Page 22: ...22...

Page 24: ...24...

Page 26: ...26...

Page 28: ...28...

Page 30: ...30...

Page 32: ...32...

Page 34: ...34...

Page 36: ...36...

Page 38: ...38...

Page 40: ...40...

Page 42: ...42...

Page 44: ...44...

Page 46: ...46...

Page 48: ...48...

Page 50: ...50...

Page 52: ...52 2 3 4 1 5 27 26 25 7 24 6 8 9 10 23 22 11 12 15 14 13 16 11 13 18 19 5 21 20 17...

Page 58: ...58 NOTES...

Page 59: ...59 NOTES...

Page 60: ......