KE-2070/2080 MS

Parameter

3-3. Origin

rough

adjustment

3-3-1. Function

Perform teaching so that the 1st mark of the calibration block is located at the center of the

OCC during home position return.

3-3-2. Required

jig

This setup requires no jigs.

3-3-3. Operation

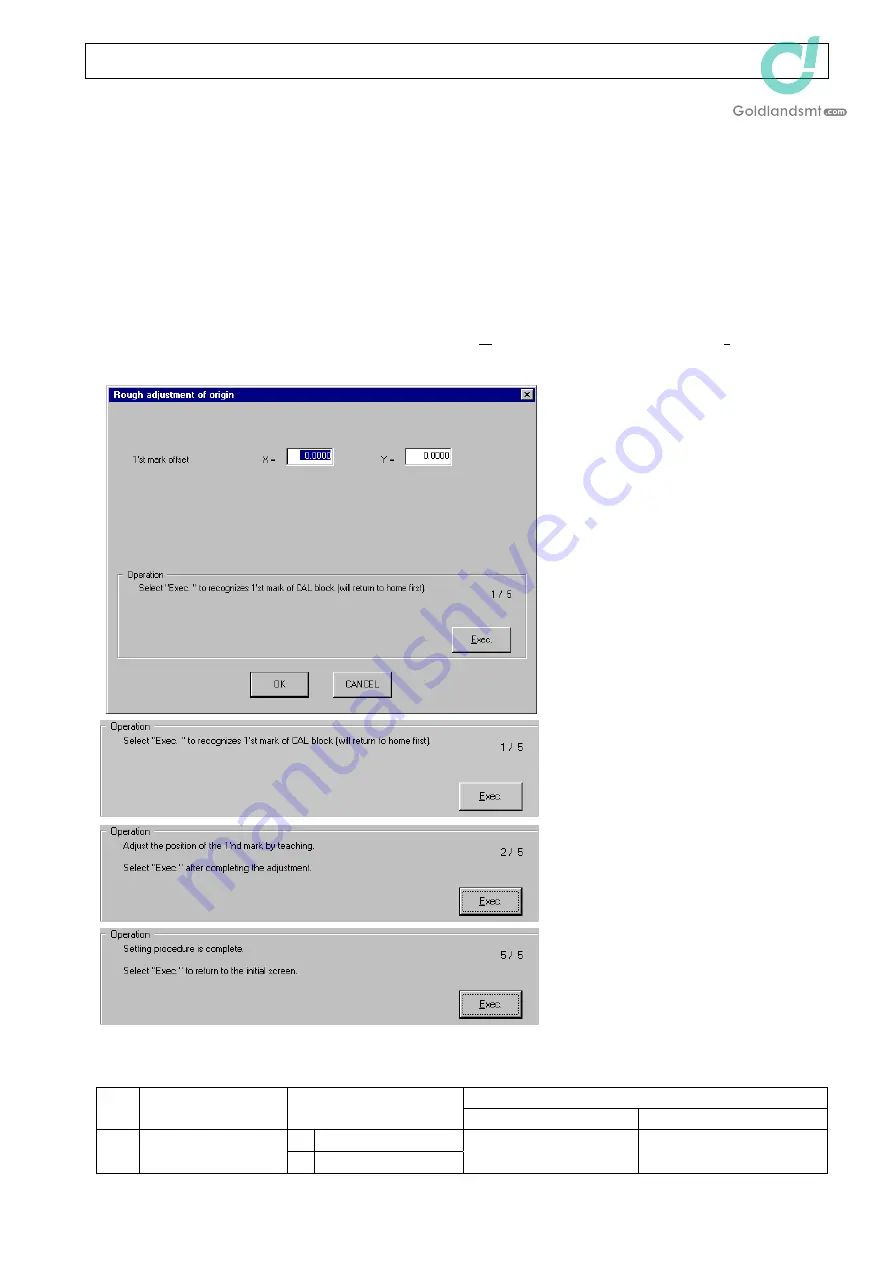

If you select [Rough adjustment of origin (R)...] from the [Initial set-up (I)] menu, the

following [Rough adjustment of origin] dialog box will appear.

<Screen 1/5>

Select [Exec.] when ready.

When [Exec.] is selected, the OCC is

moved to the 1st mark of the CAL

block and the mark is recognized after

the home position return has been

completed.

According to the recognition results,

the offset to the design value is

displayed.

If an error occurs during recognition

of the mark, the offset display is

cleared.

<Screen 2/5>

Using the teaching function, adjust

the CAL block position while

checking the OCC monitor so that

the 1st mark is located around the

center of the vision field. (Even

though there are no changes, you

must enter the teaching mode once.)

<Screen 5/5>

The setting is then completed.

Select [Exec.] to return to the initial

operation screen.

If you select [OK], the confirmation

message box is shown, and then the normal home position return (with recognition of the 1st

mark of the CAL block) is performed.

MSP value is incorrect.

No. Item

MSP

allowable

value

Faulty part

Adjustment (check) item

X

−

2.0 to 4.0 mm

1

First mark offset

Y

−

1.0 to 5.0 mm

Home position return

inoperable

3-5

Rev. 1.00