– 19 –

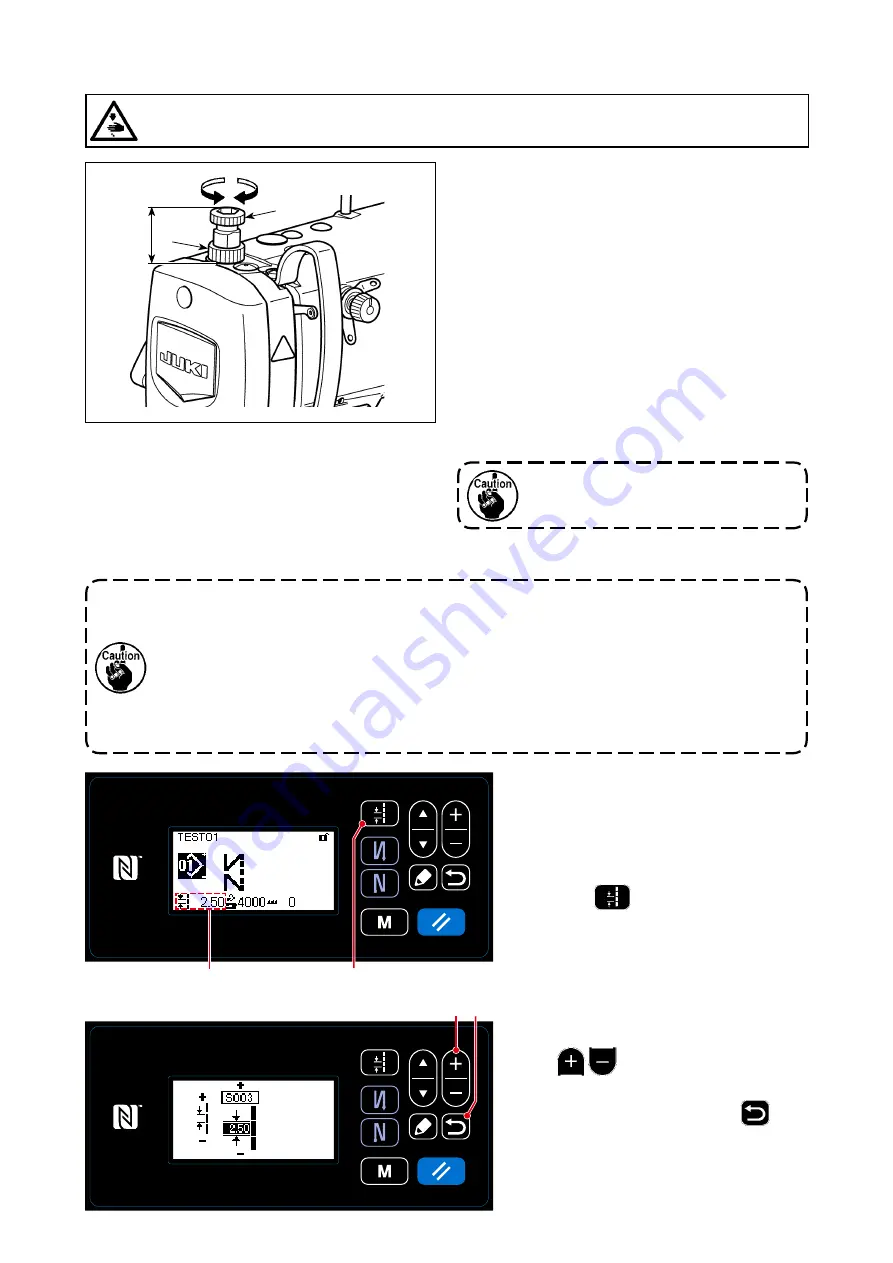

3-6. Presser foot pressure

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

1) Loosen nut

❷

. As you turn presser spring regula-

tor

❶

clockwise (in direction

A

), the presser foot

pressure will be increased.

2) As you turn the presser spring regulator

❶

count-

er-clockwise (in direction

B

), the pressure will be

decreased.

3) After adjustment, tighten nut

❷

.

The standard value of the height

C

of presser spring

regulator

❶

is as follows :

• S type : 31.5 to 29 mm

(approx. 40 to 45 N / 4 to 4.5 kg)

• H type : 31.5 to 28 mm

(approx. 50 to 60 N / 5 to 6 kg)

Stitch length is displayed in section

A

on

the panel. (Example of display : 2.50 mm)

[How to adjust]

1) Display the stitch pitch entry screen by

pressing

❼

.

3-7. Adjusting the stitch length

A

B

C

❶

❷

2) The value displayed is changed by press-

ing

❷

. (In increments of 0.05

mm ; Input range : -5.00 to 5.00)

3) Confirm your entry by pressing

❻

.

Then, the sewing screen is displayed.

To avoid personal injury, never put your

fingers under the presser foot.

❷ ❻

A

❼

1. There may be the cases where the feed amount of the operation panel and the actual sewing

pitch are different from each other in case of the use in the state other than the standard

delivery or material used. Compensate the pitch in accordance with the sewing product.

2. Be aware that interference between the throat plate and feed dog can occur depending on

the gauge used. Be sure to check the clearance in the gauge to be used. (The clearance

must be 0.5 mm or more.)

3.

When you have changed the stitch length, feed dog height or feed timing, run the sewing

machine at a low speed to make sure that the gauge does not interfere with the changed part.