−

9

−

3. CONFIGURATION

3-1 Adjusting the needle stop position

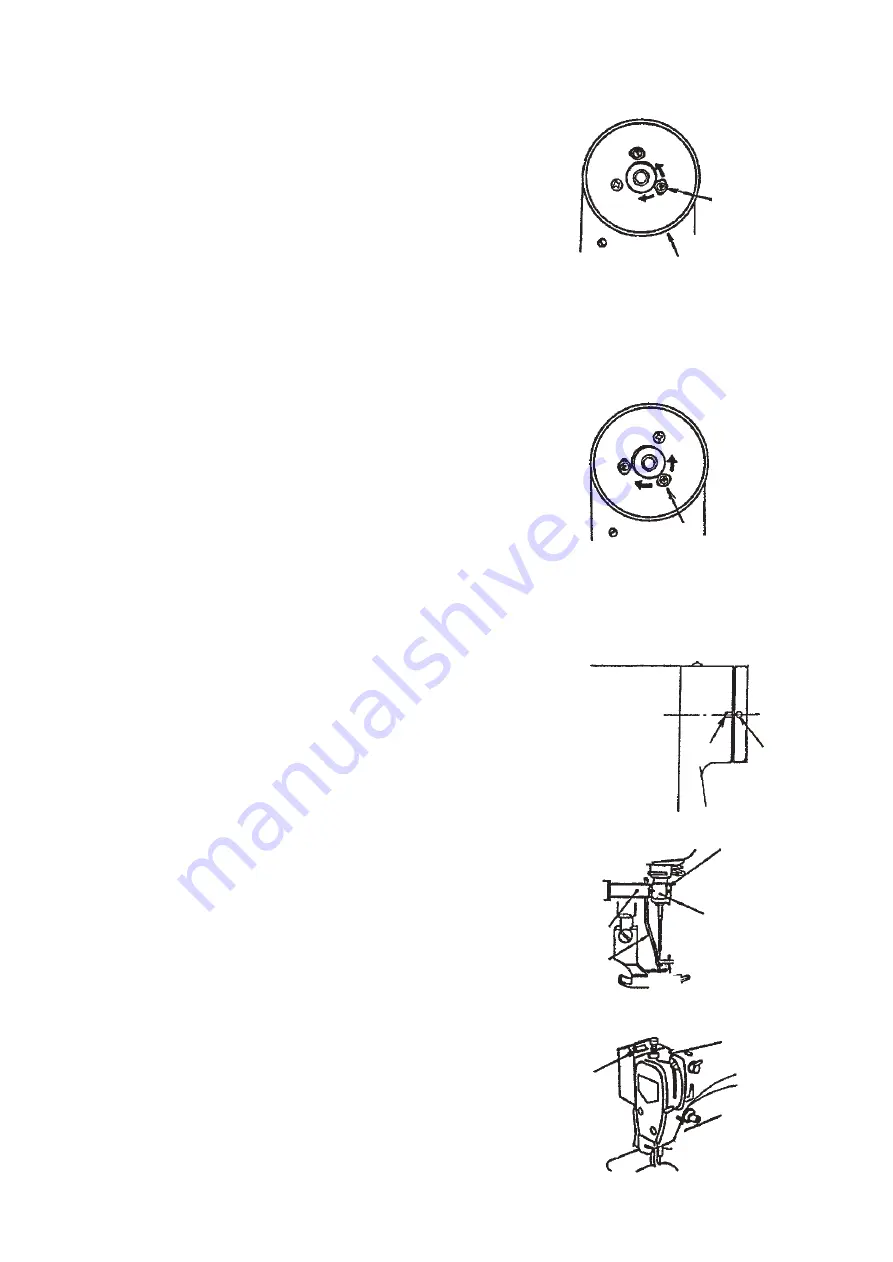

1) Adjusting the upper stop position (Upper stop position

after thread trimming)

The standrad needle stop position is obtained, when

needle stops after thread trimming, by aligning the red

marker dot on the machine arm with the white marker

dot on the handwheel.

Stop the needle in its highest position, and loosen screw

(A) in the figure on the right to perform adjustment within

the slot of the screw.

○

To advance needle stop position

→

Direction (1)

○

To delay needle stop position

→

Direction (2)

2) Adjusting the lower stop position

The lower needle stop position when the pedal is

returned to the neutral position after the front part of

the pedal is depressed can be adjusted by loosening

screw (B) in the figure on the right and adjusting within

the slot of the screw.

○

To advance needle stop position

→

Direction (1)

○

To delay needle stop position

→

Direction (2)

[Caution] Do not rotate the machine with screws (A)

and (B) loosened.Just loosen the screws,

and do not remove them.

3-2 Adjusting the wiper (WB type)

1. Adjusting the wiper position

Adjust the wiper position in accordance with the thickness

of fabric to be sewn.

Normally, adjust it as follows :

1) Turn the handwheel in the normal direction to align white

marker dot (1) with marker dot (2) on the machine arm.

2) Insert wiper (3) into wiper shaft (4) so that a clearance

of 2 mm is provided between the top end of the wiper

and the top end of the needle. At this time, adjust so

that the distance from the flat section of the wiper to

the center of the needle is 1 mm. Securely fix the wiper

with wiper adjusting screw (5) as if pressing wiper (3)

with wiper collar (6) .

[Caution] Do not loosen the wiper solenoid setscrew.

When the wiper is not used, turn OFF the

wiper seesaw switch.

(1)

(2)

(A)

(1)

(2)

(B)

(1)

(2)

(5)

(4)

(3)

(6)

1 mm

2 mm

Fig. 4

Handwheel

Fig. 5

Fig. 6

Fig. 7

Wiper seesaw

switch

Fig. 8