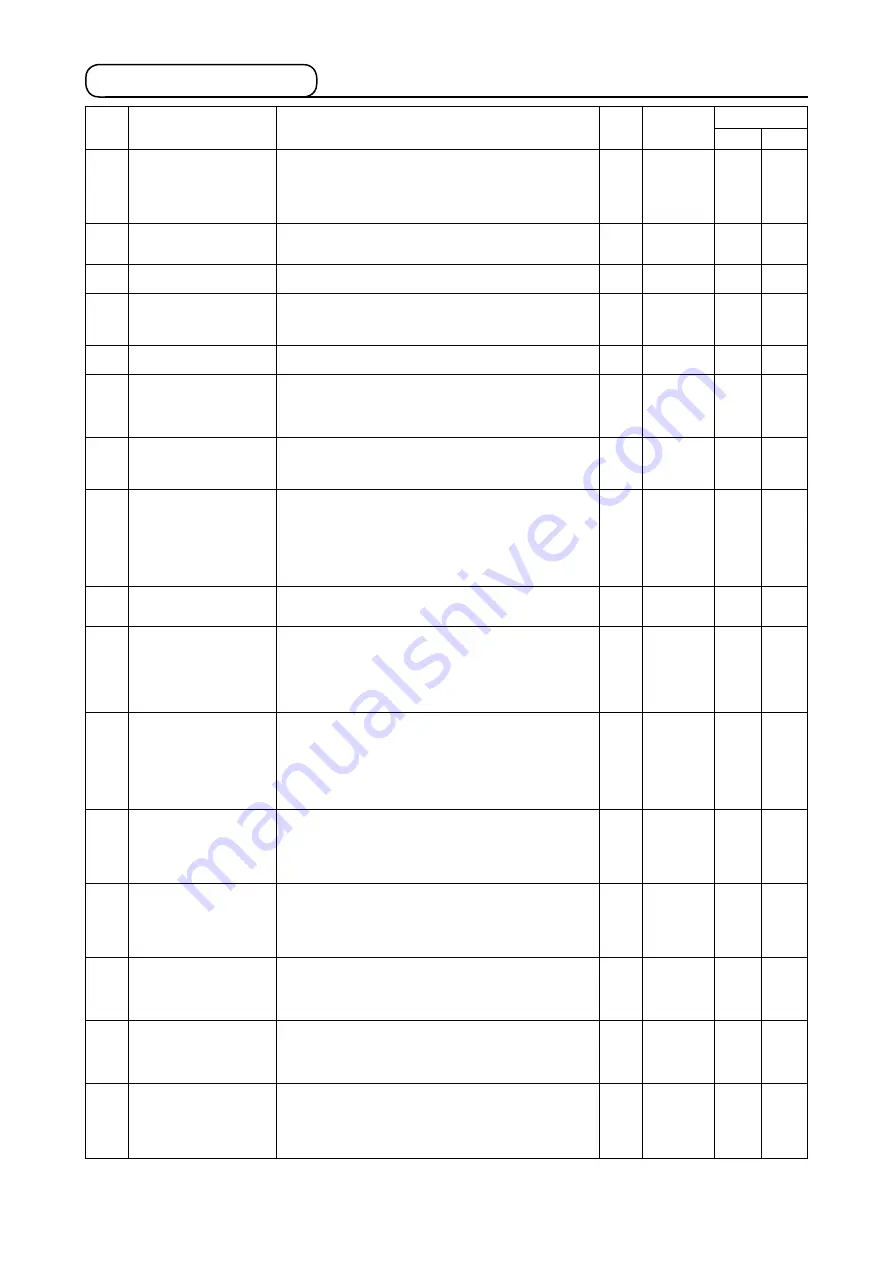

No.

Item

Description

Level

Setting

range

Default

AS-7

AH-7

P01 Maximum sewing speed

The maximum sewing speed reached by fully depressing

the pedal is set with this function setting item. The maximum

sewing speed can be changed within the sewing speed range

specified for [P68 Maximum sewing speed].

* The maximum sewing speed can also be changed using the

+ - switch on the operation panel.

U

100-[P68]

(sti/min)

4000

3500

P04 Reverse feed stitching

speed at the beginning of

sewing

The sewing speed to be used during the reverse feed stitching

at the beginning of sewing is set with this function setting item.

U

100-3000

(sti/min)

1900

1900

P05 Reverse feed stitching

speed at the end of sewing

The sewing speed to be used during the reverse feed stitching

at the end of sewing is set with this function setting item.

U

100-3000

(sti/min)

1900

1900

P06 Overlapped stitching speed The sewing speed to be used during the overlapped stitching is

set with this function setting item.

* This speed can also be changed using the relevant switch

on the operation panel.

U

100-3000

(sti/min)

1900

1900

P07 Sewing speed for soft start The sewing speed for soft start at the beginning of sewing is set

with this function setting item.

U

100-1500

(sti/min)

800

800

P08 Soft start function

The number of stitches to be sewn with the soft-start function at

the beginning of sewing is set with this function setting item.

0: The soft-start function is not selected

1 - 99: The number of stitches to be sewn with the soft-start

function

U

0-99

(Stitches)

1

1

P09 Sewing speed of the con-

stant dimension sewing

This parameter is used to set the sewing speed to be employed

when the constant dimension sewing is performed.

* The sewing speed can be changed with the switch on the

operation panel.

U

200-[P68]

(sti/min)

4000

3500

P10 Setting of the reverse feed

stitching at the end of con-

stant dimension sewing

This parameter is used to set whether or not the reverse feed

stitching is automatically performed at the end of constant

dimension sewing.

ON: Reverse feed stitching is automatically performed at the

end of sewing

OFF: Sewing machine stops sewing before starting reverse

feed stitching at the end of sewing. It performs reverse feed

stitching when the front part of pedal is depressed.

U

ON/OFF

ON

ON

P11 Selection of operation of

BTSW

This parameter is used to select the operation of the BTSW.

0: Reverse feed stitching at the midpoint of sewing

1: Needle up / down correction switch

0

0

P12 Changeover of the reverse

feed stitching at the start

of sewing between Auto /

Manual

The sewing speed for the reverse feed stitching at the begin-

ning of sewing is set with this function setting item.

0: The reverse feed stitching is performed by manually oper-

ating the pedal.

1: The reverse feed stitching is performed at the sewing

speed set with [P04 Reverse feed stitching speed at the

beginning of sewing].

U

0-1

1

1

P13 Function of stop immedi-

ately after the reverse feed

stitching at the beginning of

sewing

Operation to be carried out at the end of the reverse feed stitch-

ing at the beginning of sewing is selected with this function

setting item.

CON: The sewing machine does not stop temporarily after

completion of the reverse feed stitching at the beginning of

sewing

STP: The sewing machine stops temporarily after completion

of the reverse feed stitching at the beginning of sewing

U

CON/STP

CON

CON

P15 Changeover of the needle

up/down correction function

The function of needle up/down correction switch is changed

over with this function setting item.

0: Needle up/down correction

1: One stitch correction

2: Continuous half stitch

3: Continuous one stitch

U

0-3

0

0

P18 Correction of solenoid-on

timing for the reverse feed

stitching at the beginning of

sewing

Stitch alignment can be carried out by changing the timing

of actuating the reverse-feed stitching solenoid at the time of

reverse feed stitching at the beginning of sewing. When the

set value for this parameter is increased, the length of stitch at

the end of A process is increased and the length of stitch at the

beginning of B process is decreased.

U

0-200

132

120

P19

Correction of solenoid-off

timing for the reverse feed

stitching at the beginning of

sewing

Stitch alignment can be carried out by changing the timing

of releasing the reverse-feed stitching solenoid at the time of

reverse feed stitching at the beginning of sewing. When the set

value for this parameter is increased, the length of stitch at the

beginning of B process is increased.

U

0-200

148

160

P25 Correction of solenoid-on

timing for the reverse feed

stitching at the end of sew-

ing

Stitch alignment can be carried out by changing the timing

of actuating the reverse-feed stitching solenoid at the time of

reverse feed stitching at the end of sewing. When the set value

for this parameter is increased, the length of stitch at the begin-

ning of C process is increased.

U

0-200

100

112

P26

Correction of solenoid-off

timing for the reverse feed

stitching at the end of sew-

ing

Stitch alignment can be carried out by changing the timing

of releasing the reverse-feed stitching solenoid at the time of

reverse feed stitching at the end of sewing. When the set value

for this parameter is increased, the length of stitch at the end of

C process is decreased and the length of stitch at the beginning

of D process is increased.

U

0-200

151

158

*

Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at

the time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated. If

it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

6. Function setting list

– 29 –