– 9 –

4-8. Adjusting the thread take-up spring

Refer to

"I-4-8. Adjusting the thread take-up spring" p.12

the AMS-224EN.

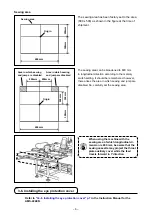

4-7. Intermediate presser height

Press INTERMEDIATE PRESSER SET-

TING button

A

and adjust with TEN keys

B

so that the clearance between the bottom

end of intermediate presser and the cloth is

-0.5 to 0.5 mm (thickness of thread used).

When raising the intermediate presser height, turn the pulley by hand to lower the needle

bar, and confirm that the needle bar does not interfere with the intermediate presser.

For the intermediate presser, the height setting range displayed is from 0 to 7 mm. It has

been factory-set to the range from 0 to 4 mm as an actual measurement at the time of ship-

ment. Be aware that, if the set value of the intermediate presser height is 3 mm or less, the

intermediate presser can interfere with the needle hole guide.

A

B

The actual height of the intermediate presser is 3 mm lower than the value entered with the TEN keys.

(Example)

Value entered with the TEN keys Actual height

7mm

4mm

4mm

1mm

3mm

0mm

Enter the value of the intermediate presser height that does not cause interference between the inter-

mediate presser and the needle hole guide referring to the aforementioned (Example).

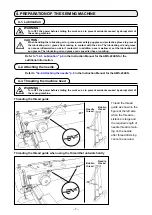

4-6. Adjusting the thread tension

Refer to

"I-4-6. Adjusting the thread tension" p.11

in the Instruction Manual for the AMS-

224EN.

• Clearance is large

→

Well-tensed seam is produced

Clearance is small

→

Small clearance or no clearance (the state that the material is slightly pressed

by the intermediate presser) is effective to prevent stitch skipping and isolated idling

loops which are produced when the needle penetrates the bobbin thread.

-0.5 mm to 0.5 mm

(reference)