6

Figure 1. Adjustable supports

3. TRANSPORTATION, INSTALLATION AND COMMISSIONING

3.1. Transportation method

The unit requires careful protection against damage and accidental overturning during transportation. Glass elements and painted

surfaces are especially vulnerable. The equipment must be in an upright (working) position both when transporting and when moving. After

installing the equipment in a specific location, the network connection must be made after a minimum of 6 hours.

3.2. Storage method

The cabinet must always be stored in an upright position. Do not store the equipment exposed to direct sunlight or other weather

conditions (rain, snow, etc.).

3.3. Operating site requirements

The equipment should be installed in a dry, well ventilated place that allows good air circulation (distance between the wall and the unit

should be at least 10 cm), away from heat sources and devices that generate air flow (including fans, air conditioners).

Do not install the equipment in locations exposed to direct sunlight, rain, snow, etc.

Make sure that the cross-section of the power lines is suitable for the current power consumption.

3.4. Equipment installation and preparation for operation

Place the cabinet on the work surface and level it horizontally with the adjustable supports (Figure 1). Precise horizontal positioning

of the equipment affects the reduction of unit noise and guarantees condensate drainage.

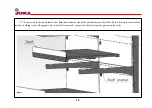

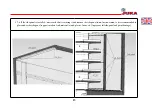

Set the brackets to the desired height and install the shelves on them.

It is necessary to install the cabinet not closer than 2m from the heating devices in

order to ensure its normal operation. Do not use the cabinet when it is exposed to direct

sunlight, air flows from air conditioners, fans and heaters

Wash the interior and exterior surfaces of the cabinet with non-corrosive and non-

abrasiv

3.5. Connection and commissioning

Requirements for operation:

а) After transportation or storage at low temperatures, keep the cabinet at a temperature

not lower than the operating temperature for 24 hours before start-up. Starting equipment

that has not been warmed up can cause the compressor to jam and result in product failure

b) products intended for display in refrigeration equipment should be loaded on the shelves evenly, cooled to the temperature of the

working volume;

c) place products in such a way that they do not interfere with the air circulation between the evaporator and the internal volume of the

equipment;

Height adjustment

Summary of Contents for ADI125

Page 1: ......

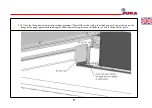

Page 12: ...12 3 7 5 Unscrew the self tapping screws and remove the rack plugs on the connection side...

Page 27: ......