SL600AC SLIDING GATE OPERATOR

6

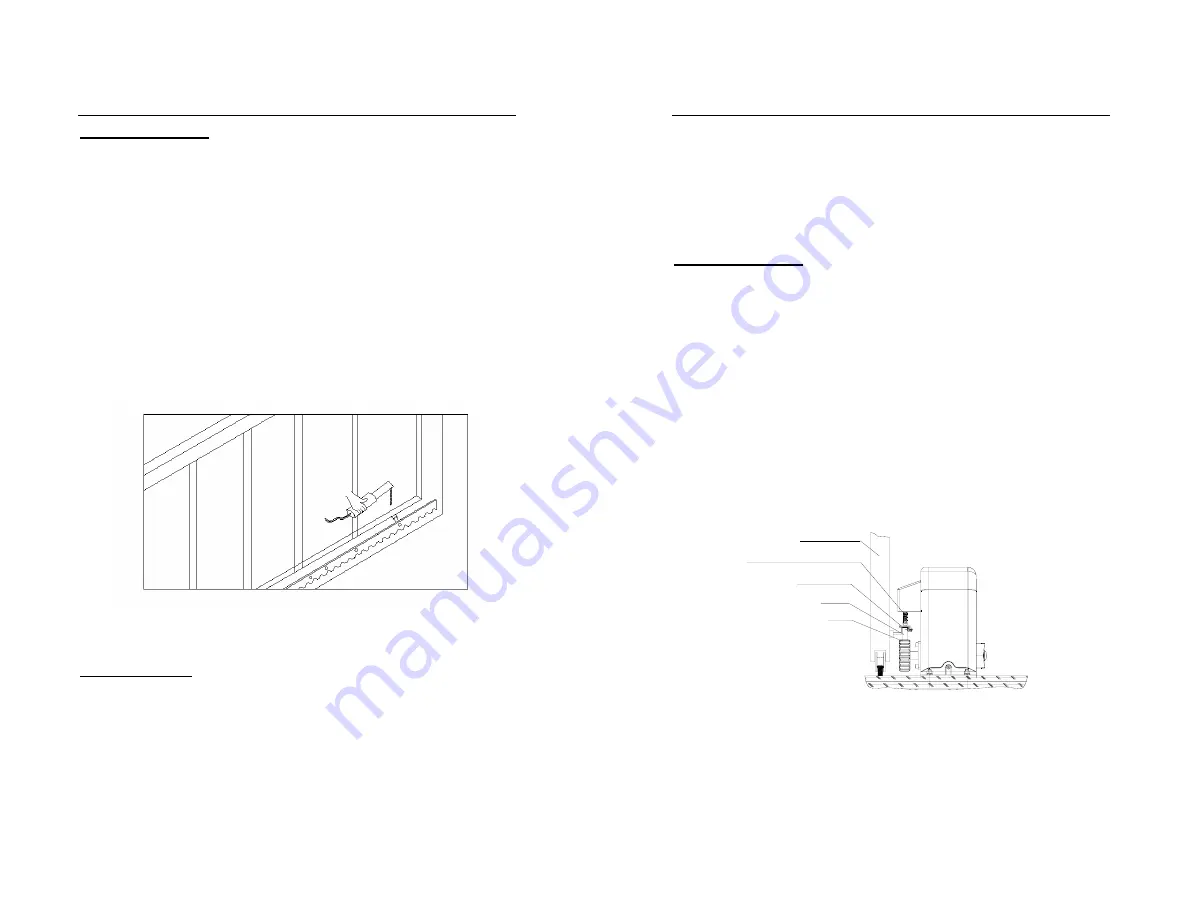

Installation of Rack

z

Fix the three nuts (in the same package with rack) on the rack

element.

z

Lay the first piece of rack on the gear and weld the first nut on the

gate.

z

Move the gate manually, checking if the rack is resting on the

gear, and weld the second and third nut.

z

Bring another rack element near to the previous one. Move the

gate manually and weld the three nuts as the first rack, thus

proceeding until the gate is fully covered.

z

When the rack has been installed, to ensure it meshes correctly

with the gear.

z

The space between rack and gear is about 0.5mm.

Fig.4

5. Adjustment

Spring limit switch

z

To ensure safety, it is recommended to install limit switches at

both ends of the gate to prevent the gate from sliding out of the

rails. The rails must be installed horizontally.

z

Install the limit block as shown in Fig.5 and Fig.6. The spring limit

switch and blocks are used to control the position of the gate.

SL600AC SLIDING GATE OPERATOR

7

z

Release the gear with the key and push the sliding gate manually

to pre-determine the position, fix the block to the rack and lock

the gear by push up the release bar. Moving the gate electrically,

adjust the block to the proper position until the position of the

opening and closing meet the requirement.

Magnetic limit switch

z

To ensure safety, it is recommended to install limit switches at

both ends of the gate to prevent the gate from sliding out of the

rails. The rails must be installed horizontally.

z

Install the limit block as shown in Fig.5 and Fig.6. The magnetic

of limit switch and blocks are used to control the position of the

gate.

z

Release the gear with the key and push the sliding gate manually

to pre-determine the position, fix the block to the rack and lock

the gear by push up the release bar. Moving the gate electrically,

adjust the block to the proper position until the position of the

opening and closing meet the requirement.

Spring limit switch

Gear

Sliding gate

Rack

limit block

Spring of limit switch