14

138301_Rev_G 10.4.11

Gas Pressure

Correct gas pressure is essential for efficient and safe

operation of the GF 400 BV gas stove. It is important

that the correct pressure is established at the time of

the installation. Proper gas pressure provides a consis-

tent flow of gas to the appliance and is instrumental in

checking for gas leaks.

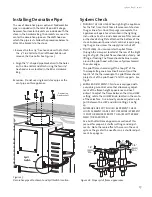

Pressure Test: Attach a manometer to the appro-

priate test point on the valve. See fig. 19. The gauge

connections are located on the front of the valve under

the On/Off/Pilot- knob. Gauge connections are identi

-

fied by:

E - for Inlet or Supply Pressure (the amount of gas

coming to the valve.)

A - for Manifold Pressure (the amount of gas that

is coming out of the valve to the burner.)

ALWAYS TEST PRESSURES WITH VALVE CONTROL

KNOB SET ON HIGH.

INLET GAS PRESSURES

(inches water column)

MIN

MAX

NATURAL GAS 5.0

7.0

PROPANE

12.0

14.9

The appliance and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing on that system

at test pressures in excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas

supply line by closing its individual manual gas

shut-off valve (gas cock) during any pressure testing

of the gas supply piping system that is equal to or

less than pressures of 1/2 psig (3.5 kPa).

MANIFOLD PRESSURES

(inches water column)

MIN

MAX

NATURAL GAS 1.2

3.8

PROPANE

2.9

11.0

Figure 19. Pressure test points.

Leak test:

1. Mix a 50-50 solution of water and dish

soap.

2. Light appliance- see lighting instructions

on the inside back cover of this manual or

on the stove’s rating plate.

3. Brush or spray all joints and connections

with the soapy water solution.

4. If bubbles appear at any connection or

seam or a gas odor is detected, imme-

diately turn gas control knob to the OFF

position.

5. Tighten or reconnect the leaking joint

and retest for any gas leaks.

Figure 18. Supply valve connection fittings.

E

A