8

139467_03 GF 370 DV II June 2015

Venting Requirements

There are three types of venting configurations ap-

proved for use with this appliance:

• Vertical Venting / Vertical Termination

• Vertical Venting / Horizontal Termination

• Horizontal Venting / Snorkel Termination

This appliance is approved for use with the 4/6

direct vent systems manufactured by the companies

listed on page 8. Use parts of one manufacturer only

- DO NOT MIX VENT COMPONENTS FROM DIFFERENT

MANUFACTURERS WITHIN THE SAME SYSTEM.

Installation of any components not manufac-

tured or approved by Jøtul or failure to meet all clear-

ance requirements will void all warranties and could

result in property damage or bodily injury.

The approved vent configurations described

in this manual are derived from extensive testing

under controlled laboratory conditions. Gas appliance

performance can be negatively affected by variables

present in the installation environment, i.e.; atmo-

spheric pressure, strong prevailing winds, adjacent

structures and trees, snow accumulation, etc. These

conditions should be taken into consideration by the

installer and stove owner when planning the vent

system design.

Vertical Venting and Termination

The Jøtul GF

370

DV II can be vertically vented

through a roof or ceiling. Follow these guidelines

Steep roofs, nearby trees, or predominantly windy

conditions, can promote poor draft or down

draft conditions. In such cases, an increase to the

height of the vent may improve performance.

If an offset or elbow is necessary in the vertical

rise, the vent pipe must be supported every three feet

to avoid excessive stress on the offsets. Use listed Wall

Straps from any of the approved vent suppliers.

A maximum of two 90° or four 45° elbows may be

used in a vertical termination. Whenever possible,

use 45° elbows instead of 90° elbows as they

offer less restriction to the flow of flue gases and

intake air.

A listed firestop is required at any floor

penetration. The opening should be framed in

according to the manufacturer’s instructions.

Always maintain a minimum 1" clearance from

all sides of the vertical vent system to any

combustible material.

Minimum vertical termination height: 6 ft. of

vent pipe.

Approved Vent Manufacturers

The Jøtul GF

370

DV II stove is approved for installa-

tion with direct vent chimney components supplied

by the following manufacturers:

M&G DuraVent, Inc. (Direct Vent Pro Series)

P.O. Box 1510

Vacaville, CA 95696-1510

800-835-4429

Selkirk Corporation

1301 W. President George Bush Hwy, Suite 330

Richardson, TX 75080-1139

800-992-8368

American Metal Products (Amerivent)

8601 Hacks Cross Rd.

Olive Branch, MS 38654

800-423-4270

Security Chimneys International Limited

2125 Monterey, Laval, Québec

Canada, H7L 3T6

450-973-9999

Metal-Fab, Inc.

P.O. Box 1138

Wichita, KS 67201

316-943-2351

ICC, Inc.

400 J-F Kennedy St. Jerome, Quebec

Canada, J7Y 4B7

450-565 6336

Bernard Dalsin Manufacturing Co. (Pro Form)

5205 208th Street West

Farmington, MN 55024

651- 460-1080

IMPORTANT

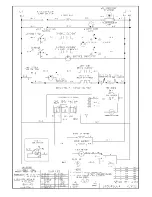

• JOINT SEALING

REQUIREMENT:

APPLY A 1/8” BEAD OF

HIGH-TEMPERATURE

SEALANT OR MIL-

PAC® TO THE MALE

SECTION OF THE

INNER VENT PIPE. THE

CEMENT SHOULD

FORM A SEAL BETWEEN

THE INNER AND OUTER PIPES.

DO NOT USE SILICONE.

SEE FIG. 6. SEE VENT MANUFACTURER’S INSTRUCTIONS.

• NEVER MODIFY ANY VENTING COMPONENT, OR

USE ANY DAMAGED VENTING PRODUCT.

• THE GAS APPLIANCE AND VENT SYSTEM MUST

BE VENTED DIRECTLY TO THE OUTSIDE OF THE

BUILDING AND NEVER ATTACHED TO A CHIMNEY

SERVING A SOLID FUEL OR GAS BURNING

APPLIANCE. EACH DIRECT VENT GAS APPLIANCE

MUST HAVE ITS OWN SEPARATE VENT SYSTEM.

COMMON VENT SYSTEMS ARE PROHIBITED.

• IF VENTING SYSTEM IS DISASSEMBLED FOR ANY

REASON, REINSTALL PER THE MANUFACTURER’S

INSTRUCTIONS PROVIDED FOR THE INITIAL

INSTALLATION.

Figure 6.