English –

17

INSTALLATION

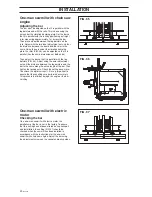

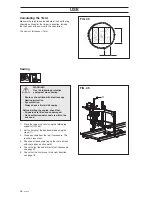

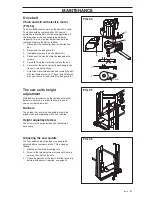

Setting up the Saw Carriage (FIG. 24)

WARNING!

The saw carriage is heavy. Two

persons are required when setting

up. Always wear boots with steel

toecaps.

CAUTION!

Do not drop the saw carriage onto the rails or

any other hard surface too heavily. This will

result in permanent damage to the saw

carriage’s bearings.

Do not place the saw carriage directly on the

ground so that dirt and unnecessary con-

tamination can come into contact with the

saw carriage’s wheels.

Assembly is done as follows:

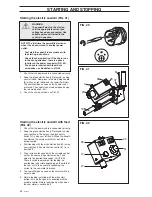

1. Fix the guide wheel’s bracket in place with a screw.

Place a 0.2 mm feeler gauge between the bearing

and rail (FIG. 26).

2. Press the bearing against the rail and tighten the

bearing bracket screw. Tightening torque: 40-50

Nm. Now remove the feeler gauge.

3. Carry out 1-2 above for the remaining guide wheels.

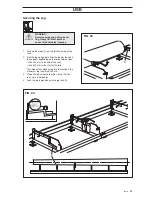

4. Position the four rail guards (FIG. 27) above the

wheel.

Saw Carriage Adjustment (FIG. 26)

The saw carriage is aligned on the rails by fitting its

lower guide wheels and rail guards. The lower guide

bearings have the task of preventing the saw carriage

from tilting and the rail guards keep the rails and the

saw carriage’s wheels free from dirt and the like.

Assembled on the saw carriage are:

• Two lower guide wheels

• Four rail guards.

!

Place the saw carriage on the rails and make

adjustments as follows:

1. Two persons take hold of the saw carriage, one on

each side. Hold the saw carriage as follows:

The

right-hand side:

under the engine console (A) on

the electric sawmill or under the saddle on the chain

saw sawmill.

The left-hand side:

in the sawmill

chassis (B).

2. Lift and place the saw carriage so that the grooves

in its wheels are positioned above their respective

rails (FIG. 25). Carefully lower the saw carriage onto

the rails.

FIG. 24

FIG. 25

FIG. 26

FIG. 27

0,2 mm

A

B

Summary of Contents for SM 2055 E

Page 35: ......

Page 36: ...2003W50 z x 6 108 89 11 26 ...