(6) 12-Gallon, 100 PSI Carpet Extractor

12-Gallon, 100 PSI Carpet Extractor (11)

3.0 Set-Up / Prepare Unit for Use

DO NOT USE ON WET SURFACES. DO NOT EXPOSE TO RAIN. STORE

INDOORS.

•

All Carpet Extractors, no matter what the time of year, are shipped with antifreeze in

the solution lines. Prior to first use, fill the tank with one quart of warm water. Attach

the hose and using the hand tool wand, flush out the system by spraying the one quart

of water through the pump.

•

Attach the 1-1/2 inch vacuum hose and the brass quick disconnect.

•

Fill the base unit (the recovery tank must be removed) with warm water (less than

100 degrees Fahrenheit). Fill to approximately 4 inches from the top. Use a liquid

detergent made for carpet cleaning or upholstery. Read and mix to the dilution ratios

as directed.

• Be sure to replace any filters back into the machine prior to use.

•

Do not use citrus acid, buterol or harsh degreasers inside the machine.

3.1 Electrical

Plug cord(s) into 20 AMP grounded wall outlet(s). 20 AMP circuits are normally found in

kitchens and bathrooms. Never remove ground prong from the plug. If a circuit breaker

trips during operation, turn machine off, reset the breaker and move the electrical cord to

a different outlet and resume operation.

3.2 Vacuum System

The extractor uses a dual vacuum motor system that provides outstanding water lift and

air flow.

Vacuum Float Assembly Warning System:

the float assembly on the vacuum stand

pipe prevents the waste tank from overflowing the stand pipe and damaging the vacuum

motors. Motors will reach a fast, high-pitched sound alerting you when the recovery tank

is about to over flow. When this happens, immediately turn OFF the vacuum switches and

empty the waste tank.

The float assembly has a filter to prevent lint and debris from entering the stand pipe.

Refer to the “Maintenance” section for removal and proper cleaning.

Recovery Tank:

the vacuum system requires the use of an external filter. The clear

view in-line filter is included with the machine and must be used on every job.

It is also necessary to use a defoamer to eliminate foam build-up in the recovery

tank which could lead to foam/moisture entering the vacuums and contributing to

early failure of the vacuum motors.

If moisture does enter the vacuum motors, contact an authorized service center. To

prevent moisture from damaging the vacuum motors during storage, empty the recovery

tank and store with the lid open.

6.0 Storage and Freeze Protection Continued

Recommended Procedure for Storage Continued

•

Disconnect the solution hose from the chemical feed and allow the system to bypass

for 10 minutes. This will work antifreeze into the pressure gauge.

•

Attach and wands and hand tools that will also be stored with the Carpet Extractor.

Open the valve for 30 seconds, directing the spray to the solution tank. Disconnect the

hose and with the valve open and the jets pointing down, depress the dimple on the

male QD. This will drain the solution out of the tool. Drain thoroughly before storing.

•

Turn off the pump and disconnect all hoses and tools. Vacuum out the solution tank

and thoroughly drain the recovery tank and vacuum hose.

To return to service, flush the pressure system by repeating the above steps, using

fresh water in place of antifreeze.

7.0 Trouble Shooting Guide

Never operate this Carpet Extractor when the equipment is not performing as expected

or when any part is visibly damaged. When repair is needed, take the equipment to an

authorized service center.

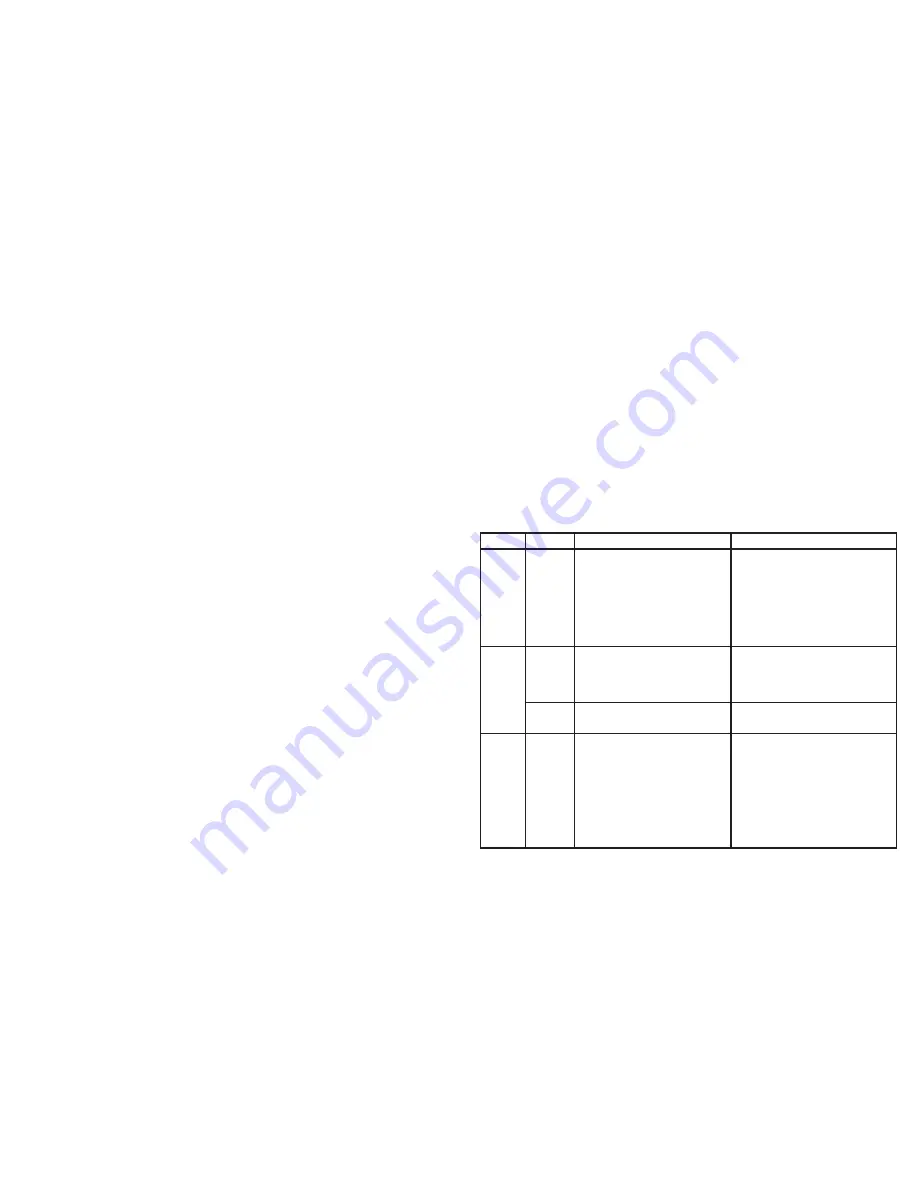

System

Problem

Possible Cause

Remedy

Vacuum

System

No Vacuum

/ Weak

Vacuum

1.

Vacuum Tank Full

2.

Float Assembly Tank Screen Dirty

3.

Float Ball Stuck

4.

Damaged or Loose Vacuum Hose

5.

Dump Valve Open

6.

Access Lid not Sealed

7.

Vacuum Hose Clogged

8.

Air Intake Grid Clogged

9.

Leak in Recovery Tank

10.

Water Coming out of Vacuum Exhaust

1.

Empty Tank

2.

Clean the Screen with Water

3.

Tap Float to Unstick then Clean

4.

Attach or Replace

5.

Close Valve

6.

Replace Gasket

7.

Clear Debris

8.

Clean

9.

Clean and Dry Area, Patch with Silicone

10.

Use a Low Foaming Detergent

Electrical

System

Unit will not

Turn On

1.

Extension Cord not Plugged In

2.

Switch not in the “On” Position

3.

Building Circuit Overloaded

4.

Wiring Connections Loose

1.

Check if Machine and Cord are Plugged In

2.

Check Switches, Replace if Necessary

3.

Reset Circuit

4.

Unplug Machine and Check for Loose

Wires

Burning

Smell

1.

Vacuum Motor Hung Up

2.

Pump Motor Hung Up

1.

Replace Vacuum Motor

2.

Replace Pump

Pump

System

Pump is not

Running

Properly

1.

No Power to the Pump

2.

Jets on Wand are Clogged

3.

In-Line Water Filter is Clogged

4.

Debris in Solution Tank Covering Inlet

5.

Kinked or Loose Hose

6.

Pump Failed

7.

Quick Disconnects are not Completely

Locked Together

8.

Heater is Clogged with Deposits

9.

Pump is Pulsating

10.

Auto Prime Valve is Open

1.

Check the Electrical System

2.

Clean Jet Filters

3.

Clean In-Line Filter

4.

Clear Debris

5.

Check and Replace Hoses if Necessary

6.

Replace Pump

7.

Snap Quick Disconnects Together\

8.

Flush Heater with System Maintainer or

Replace if Necessary

9.

Check for Clogged Jets and Clean

10.

Close Valve