TFP700

Page 2 of 4

Cautions must be understood by all dis-

ciplines (for example, sprinkler fitters,

designers, authorities having jurisdic-

tion, and material handlers) involved

with the installation of automatic sprin-

klers. Care must be exercised during

installation, and the following guide-

lines must be followed to ensure that

the sprinkler will operate properly:

• Store sprinklers properly and shield

them from extreme heat. Do not

store sprinklers in direct sunlight or

in areas of vehicles that are subject.

to extreme temperatures. Over-

heating will damage the sprinkler

by weakening the thermal sens-

ing element resulting in premature

activation.

• Sprinkler cartons are specially

designed to protect the sprinkler

during transit. Do not empty sprin-

klers from their cartons into bags or

buckets prior to installation, since

damage to the sprinklers may result.

Install the sprinklers directly from

their cartons.

• Unless otherwise modified by

NATIONAL FIRE PROTECTION

STANDARDS (NFPA) such as

NFPA 13 “Installation of Sprin-

kler Systems”, sprinkler temper-

ature ratings shall be as follows:

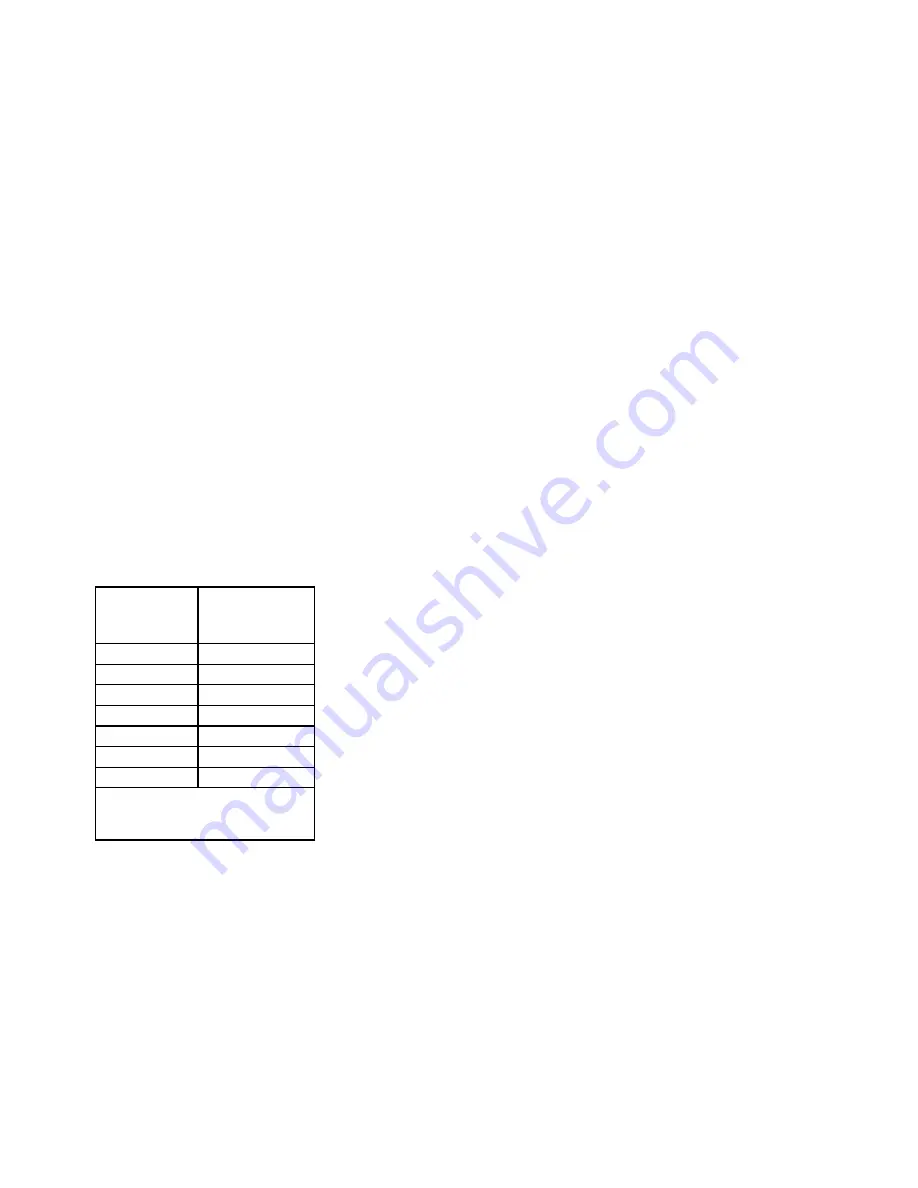

Maximum

Ceiling

Temperature,

°F (°C)

Sprinkler

Temperature

Rating,

°F (°C)

100 (38)

135-170 (57-77)

150 (66)

175-250 (79-107)

225 (107)

250-300 (121-149)

300 (149)

325-375 (163-191)

375 (191)

400-475 (204-246)

475 (246)

500-575 (260-302)

625 (329)

650 (343)

TABLE A

TEMPERATURE

RATINGS

Over-heating will damage the sprin-

kler by weakening the thermal sens-

ing element resulting in premature

activation.

• Do not install any sprinkler that

shows signs of damage. Immediately

replace all sprinklers that are dam-

aged during installation.

• Inspect glass bulb sprinklers at the

time of installation to make sure that

the bulb contains fluid. Inspection of

the glass bulb is to be made with the

sprinkler strap in place by looking

through the openings of the sprin-

kler strap.

Any glass bulb that shows evidence

of leakage or that does not have

any fluid must be discarded. Do not

install any bulb type sprinkler if the

bulb is cracked or there is a loss of

liquid from the bulb. With the sprin-

kler held horizontally, a small air bub-

ble should be present. The diameter

of the air bubble is approximately

1/16 inch (1,6 mm) for the 135°F

(57°C) to 3/32 inch (2,4 mm) for the

360°F (182°C) temperature ratings.

Loss of liquid from a bulb can cause

the sprinkler to fail to activate in a

fire. Install sprinklers in fittings with

the pipe ‘in place’. Sliding piping

through structural members with the

sprinklers in place can severely dam-

age sprinklers.

• Do not apply any thread roughen-

ing process to the sprinkler thread.

Application of this effect can cause

distortion of the frame, which may

result in leakage or damage to the

actuation mechanism.

• When starting the thread of a sprin-

kler, do not over-tighten by hand.

Excessive tightening by hand can

cause damage to the thermal sens-

ing element without knowledge to the

installer.

• Always wrench tighten the sprinklers

with the sprinkler wrench specified

for use with the specific sprinkler

being installed. Using the wrong

wrench can damage the sprinkler.

• Apply sprinkler wrenches to the

proper sprinkler wrench boss/flats

only. Do not allow the sprinkler

wrench to slip during the wrench

tightening procedure. Wrenching

the sprinkler frame arms, deflector,

or thermal sensing element, and/or

wrench slippage, will severely dam-

age the sprinkler.

• Do not over-tighten (maximum torque

is as follows: 1/2” NPT/14 ft.-lbs.; 3/4”

NPT/20 ft.-lbs.; 1” NPT/30 ft.-lbs.).

Over-tightening can distort the sprin-

kler inlet causing leakage or inability

of the sprinkler to operate properly.

• Do not attempt to make-up for insuf-

ficient adjustment in the escutcheon

plate by under- or over-tightening the

sprinkler. Over-tightening can distort

the sprinkler inlet causing leakage or

inability of the sprinkler to operate

properly. Under-tightening can result

in pipe thread leakage. Relocate the

position of the sprinkler, as neces-

sary, to facilitate the adjustment pro-

vided by the escutcheon.

• Do not remove protective devices (for

example, sprinkler straps or protec-

tive caps for concealed type sprin-

klers) until the water supply, either

temporary or permanent, is made

available to the sprinklers for pur-

poses of fire protection. Failure to

maintain the protective devices

where provided may allow damage to

occur to the thermal sensing element

with increasing risk of the sprinkler

failing to activate in a fire or causing

the sprinkler to activate prematurely.

Note

: For upright sprinklers and sprin-

klers installed more than 10 ft. (3,1 m)

above the floor, protective devices (for

example, sprinkler straps or protec-

tive caps for concealed type sprin-

klers) are permitted to be removed

from the sprinklers immediately fol-

lowing their installation. (Where instal-

lation of mechanical services or other

construction work is expected to take

place following the installation of sprin-

klers, consideration should be given to

leaving protective devices in place until

such time as the water supply is made

available to the sprinklers for purposes

of fire protection.)

• After a protective device (for exam-

ple, sprinkler straps or protective

caps for concealed type sprinklers)

is removed, inspect glass bulb sprin-

klers to make sure that the bulbs

contain fluid, and inspect fusible sol-

der type sprinklers for damage to the

fusible element and associated link

assembly parts.

Any sprinkler having a glass bulb

that shows evidence of leakage or

that does not have any fluid must

be replaced, and any sprinkler that

shows evidence of damage to the

fusible element and associated link

assembly parts must be replaced.

• Sprinklers cannot operate properly

with protective devices in place (for

example, sprinkler straps or protec-

tive caps for concealed type sprin-

klers). As applicable, refer to the

“Sprinkler Strap Instructions” pro-

vided in this data sheet.

• Sprinklers that are found to be leak-

ing or exhibiting visible signs of cor-

rosion must be replaced. Leakage

and/or corrosion may cause the

sprinkler to fail to activate in a fire,

and corrosion may cause the sprin-

kler to activate prematurely.

• Automatic sprinklers (including cover

plates of concealed type sprin-

klers) must never be painted, plated,

coated or otherwise altered after

leaving the factory. Painted, coated,

or otherwise altered sprinklers may

interfere with the sprinkler’s ability to

operate in a fire. Modified sprinklers

must be replaced.

• After a fire, bulb type sprinklers that

have been exposed to corrosive

products of combustion, but have

not operated, should be replaced if

they cannot be completely cleaned

by wiping the sprinkler with a cloth

or by brushing it with a soft bristle

brush.