5750149-UIM-D-1219

Johnson Controls Ducted Systems

11

SECTION V: ELECTRICAL POWER

ELECTRICAL POWER CONNECTIONS

Field wiring to the unit must be grounded. Electric wires that are field

installed shall conform to the temperature limitation for 63°F (35°C) rise

wire when installed in accordance with instructions. Refer to Table 6 in

these instructions for specific furnace electrical data.

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

DANGER

PROPANE AND HIGH ALTITUDE CONVERSION KITS

It is very important to choose the correct kit and/or gas orifices for the altitude and the type of gas for which the furnace is being installed.

Only use natural gas in furnaces designed for natural gas. Only use propane (LP) gas for furnaces that have been properly converted to use pro-

pane (LP) gas. Do not use this furnace with butane gas.

Incorrect gas orifices or a furnace that has been improperly converted will create an extremely dangerous condition resulting in premature heat

exchanger failure, excessive sooting, high levels of carbon monoxide, personal injury, property damage, a fire hazard and/or death.

High altitude and propane (LP) conversions are required in order for the appliance to satisfactory meet the application.

An authorized distributor or dealer must make all gas conversions.

In Canada, a certified conversion station or other qualified agency, using factory specified and/or approved parts, must perform the conversion.

The installer must take every precaution to insure that the furnace has been converted to the proper gas orifice size when the furnace is installed.

Do not attempt to drill out any orifices to obtain the proper orifice size. Drilling out a gas orifice will cause misalignment of the burner flames, caus-

ing premature heat exchanger burnout, high levels of carbon monoxide, excessive sooting, a fire hazard, personal injury, property damage and/or

death.

!

CAUTION

Use copper conductors only.

!

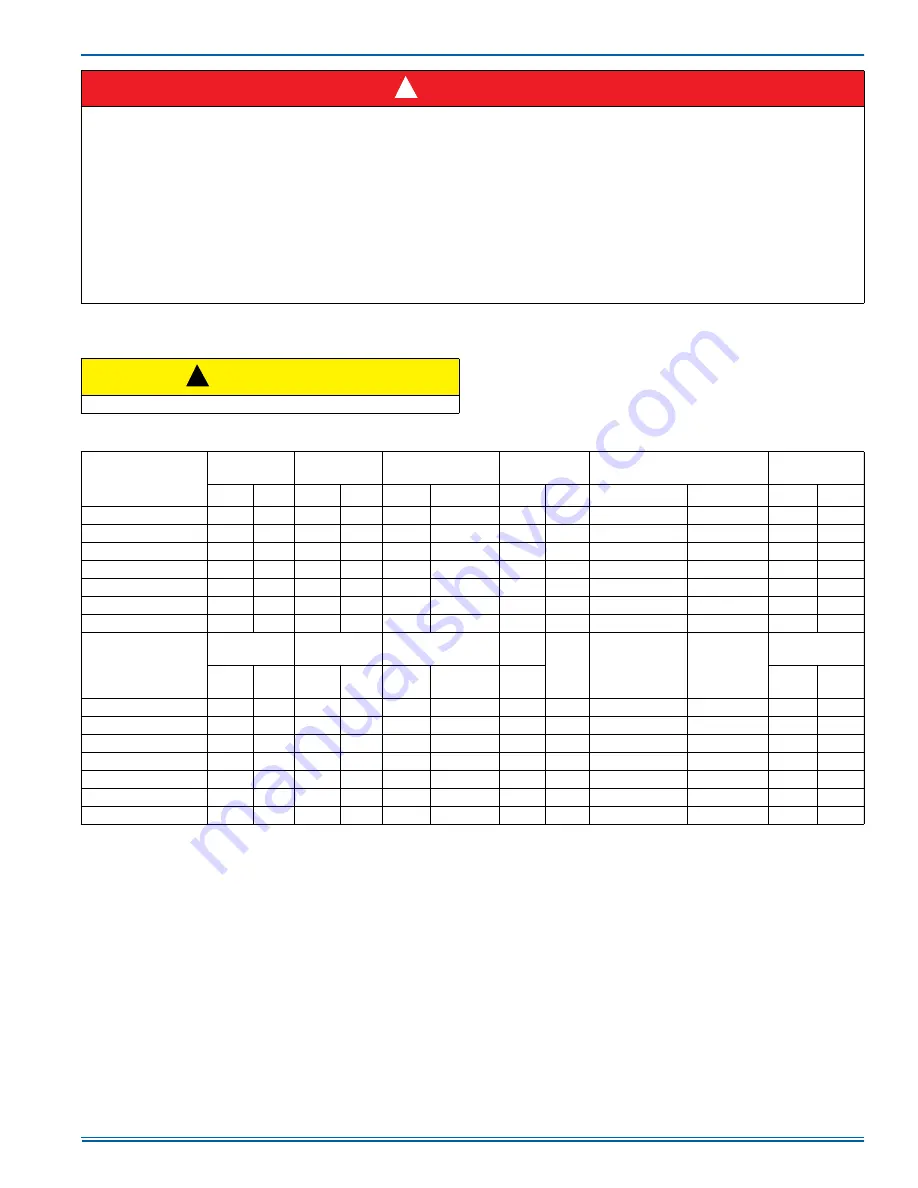

Table 6:

Ratings & Physical / Electrical Data

Model

Input

High/Low

Output

High/Low

Nominal

Airflow

Cabinet Width

High Fire

Air Temp. Rise

Low Fire

Air Temp. Rise

MBH

kW

MBH

kW

CFM

m

3

/min

in.

cm

°F °C

°F

°C

TM9V040A10

40/26

12/8

38/25

11/7

1000

28.3

14-1/2

36.8

30 - 60

17-33

20 - 50

11-28

TM9V060B12

60/39

18/11

58/37

17/11

1200

34

17-1/2

44.4

35 - 65

19-36

35 - 65

19-36

TM9V080B12

80/52

23/15

77/50

22/14

1200

34

17-1/2

44.4

40 - 70

22-39

35 - 65

19-36

TM9V080C16

80/52

23/15

77/50

22/14

1600

45.3

21

53.3

35 - 65

19-36

35 - 65

19-36

TM9V100C16

100/65 29/19

96/62

28/18

1600

45.3

21

53.3

35 - 65

19-36

30 - 65

17-33

TM9V100C20

100/65 29/19

96/62

28/18

2000

56.6

21

53.3

35 - 65

19-36

35 - 65

19-36

TM9V120D20

120/78 35/23 115/75 33/22

2000

56.6

24-1/2

62.2

35 - 65

19-36

35 - 65

19-36

Model

Max. Outlet

Air Temp.

Blower

Blower Wheel Size

AFUE Total

Unit

Amps

Recommended

Fuse or

Circuit Breaker

Amps

Gas Pipe

Connection,

NPT

Operating

Weight

°F

°C

HP

Amps inches

cm

%

Lbs.

kg.

TM9V040A10

190

88

1/2

7.7

11 x 8

27.9 x 20.3

96

9.6

15

1/2”

113

51.2

TM9V060B12

190

88

1/2

7.7

11 x 8

27.9 x 20.3

96

9.6

15

1/2”

122

55.3

TM9V080B12

190

88

1/2

7.7

11 x 8

27.9 x 20.3

96

9.6

15

1/2”

126

57.1

TM9V080C16

190

88

3/4

9.6

11 x 10 27.9 x 25.4

96

11.5

15

1/2”

136

61.7

TM9V100C16

190

88

3/4

9.6

11 x 10 27.9 x 25.4

96

11.5

15

1/2”

142

64.4

TM9V100C20

190

88

1

12.8

11 x 11 27.9 x 27.9

96

14.7

20

1/2”

145

65.7

TM9V120D20

190

88

1

12.8

11 x 11 27.9 x 27.9

96

14.7

20

1/2”

156

70.7