Subject to change without notice. Published in U.S.A.

835961-UIM-A-0112

Copyright

©

2012 by Johnson Controls, Inc. All rights reserved.

Supersedes: 550377-UIM-D-1211

Johnson Controls Unitary Products

5005 York Drive

Norman, OK 73069

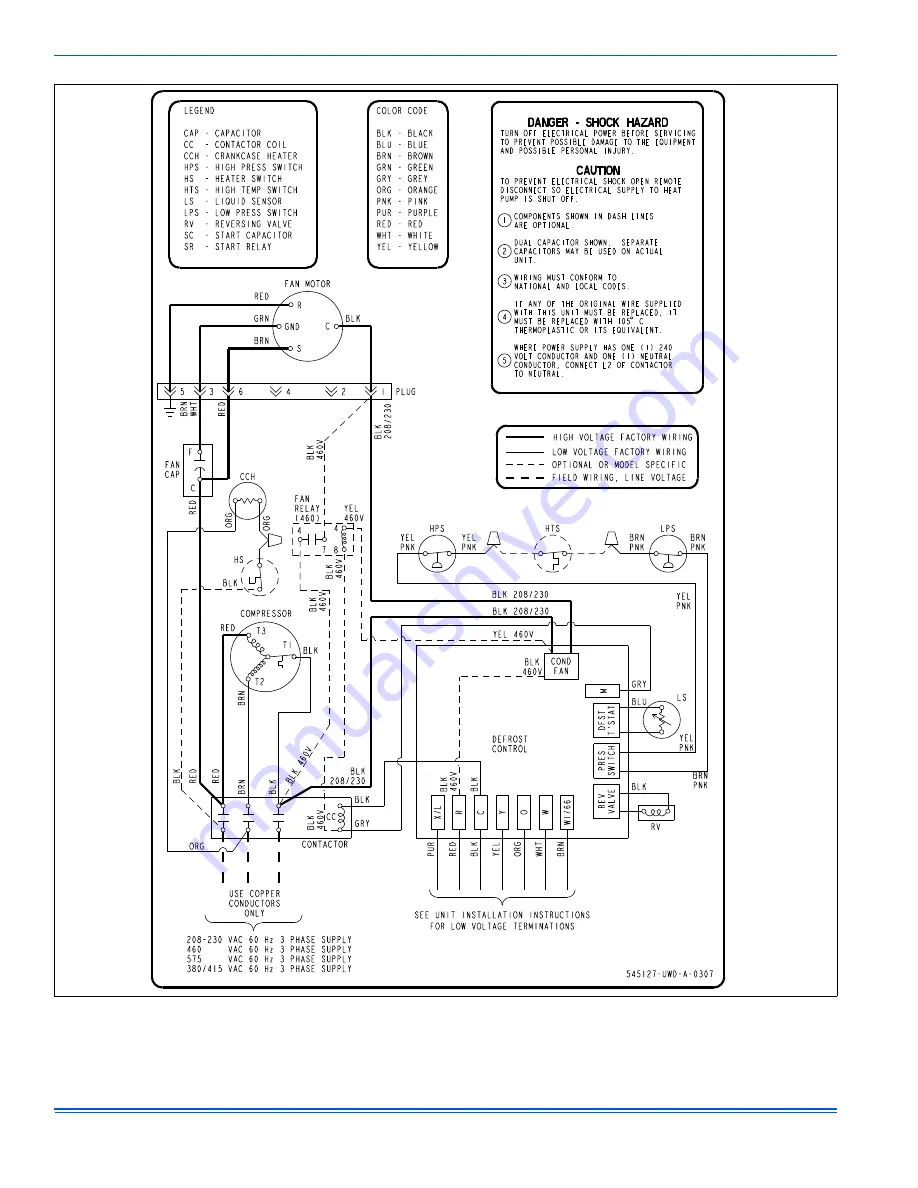

FIGURE 17:

Wiring Diagram - Three Phase (Time-Temp)