IDC INDUCED DRAFT EVAPORATIVE CONDENSERS

MAINTENANCE

S140-500 IOM (FEB 08)

Page 21

4.6 Belt Replacement and Tensioning

Replacement

When the decision is made to replace the belt, follow these

steps:

1. Lock out and tag the starter.

2. After the power has been turned off and the motor guard

removed, loosen the motor mount adjustment nuts.

3. Move the motor until there is enough slack in the belt so

it can be removed without prying.

4. Remove the old belts and inspect for unusual wear. Ex-

cessive wear may indicate problems with alignment or

sheave damage.

5. Use replacement belts from the factory to ensure a proper

belt equivalent.

6. Inspect other drive components such as bearings and

sheaves for alignment, wear, lubrication, etc.

7. Clean the sheaves of debris before installing the new

belt.

8. Install the new belt, align the drive, and tension the belt

according to the procedures outlined here.

Tensioning

Proper belt tension is very important to ensure maximum

belt life. If too little tension is applied, the belt will slip. Too

much tension can reduce belt and bearing life. It is not recom-

mended that belt dressing be used when belt slippage occurs

as this will damage the belt and cause premature failure.

1. Decrease the center distance between the sheaves (by

turning the tensioning nut counter clockwise) so the

sheaves are somewhat loose.

2. Apply tension to the belt by turning the tensioning nut

clockwise.

3. Operate the drive a few minutes to seat the belt in the

sheave grooves. Observe the operation of the drive during

start-up. A slight bowing of the slack side of the drive indi-

cates proper tension. If the slack side remains taut during

the peak load, the drive is to tight. Excessive bowing or

slippage indicates insuffi cient tension. If the belt squeals

as the motor comes on, it is not tight enough. The drive

should be stopped and the belt tightened.

NOTE: Do not overtighten the drive.

4. If the above procedure still results in the belt squealing,

but the belt is still taut on the slack side, a more precise

method of testing the belt tension must be used. In this

case, use a belt-tensioning gage available from V-belt

drive manufacturers or from the Factory.

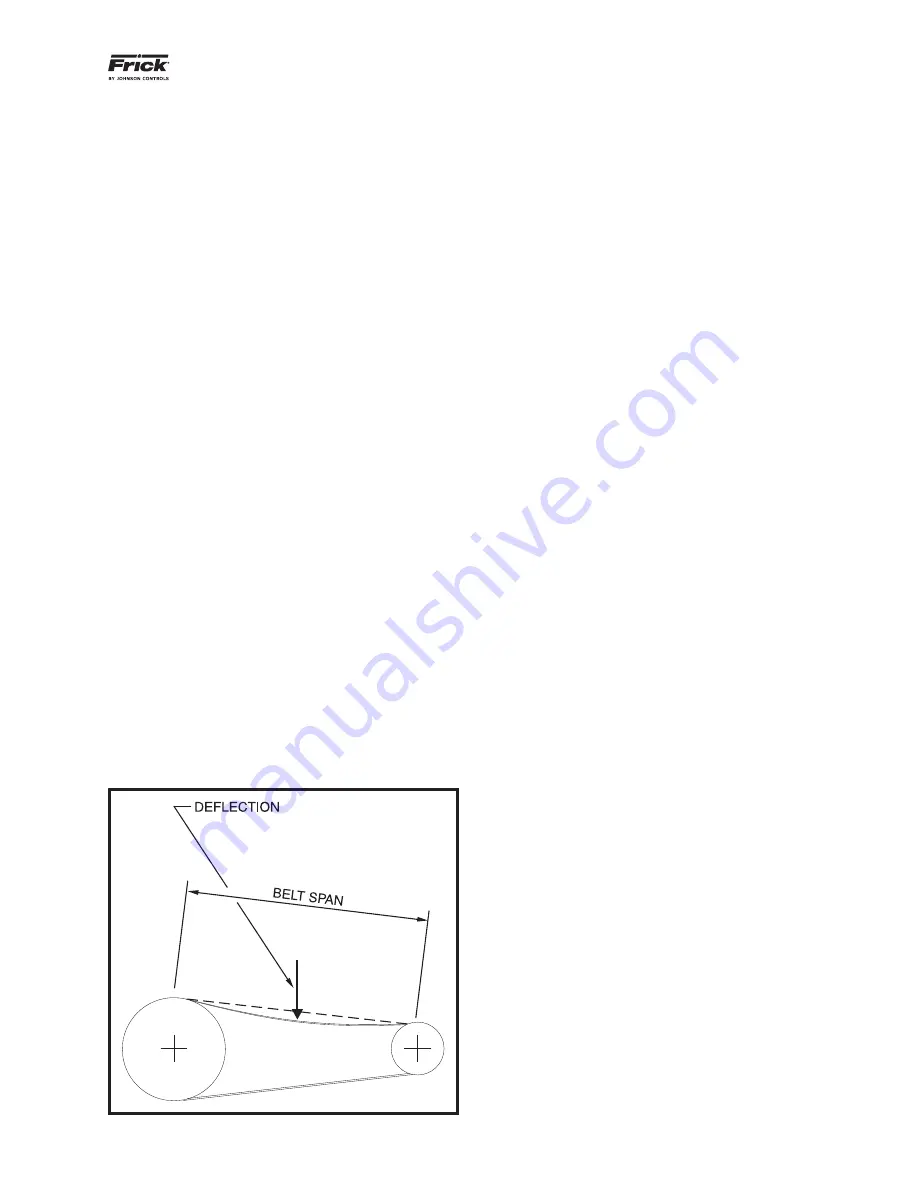

All belt tension measuring devices should include operating

instructions. These are spring-loaded devices that use a

hook to place tension on a stationary belt. Tension readings

are observed at a point where the belt defl ects a predeter-

mined distance. Tension is usually applied at the belt span’s

mid-point as measured between the tangent of belt contact

for both sheaves. Reference

Figure 4-5. Belt Tensioning

Schematic.

4.7 New Belt Run-in

During initial startup of new belts, a belt run-in procedure is

recommended. During start-up, follow these instructions:

During start-up, look and listen for unusual noise or vibra-

tion.

1. After shutting down and locking out the starter, check the

bearings and motor. If they feel hot, the belt tension may

be too tight.

2. Run the drive under full load for 24 hours of continuous

operation. Running the belts under full load allows them

to seat themselves into the grooves.

3. After running the drive, check the tension of the belts. Re-

tension to the recommended values. This run-in procedure

will reduce the future need for re-tensioning and will help

extend the life of the belts.

4.8 Coil

Assembly

An evaporative-cooled condenser’s operational readiness is

dependent on the condition of the coil. Coils that are dirty,

blocked from air-fl ow, or physically damaged may affect

overall heat transfer capability of the IDC to a signifi cant

degree.

Periodically conduct a visual inspection of the coil section

and refrigerant line connections. Remove any airborne debris

that may have collected on the face of intake louvers or on

the coils themselves. If separate air fi ltration exists prior to

the intake louvers, ensure that adequate “free area” exists

to meet intake-air CFM requirements.

Further need for cleaning or repair of an IDC coil should be

left to the judgement of a certifi ed or factory-trained service

person. Contact the local Frick representative if a coil or its

connections appears to have been signifi cantly damaged.

4.9 Water Makeup Requirements

At its rated capacity (given in tons), an IDC unit will evaporate

3 gallons/min per 100 tons.

When the water evaporates, any impurities remain. Recircu-

lating water fl ow then requires refreshing to prevent eventual

scale build up. A bleed-off valve is located on the spray pump

discharge line to bleed off an equal amount of water to that

evaporated. (3 GPM per 100 tons)

For conditions where the original water hardness is very high

or a large number of airborne contaminants may be washed

into the recirculating spray water, a higher bleed-off rate or

chemical treatment may be required. Consult a local water

treatment company for recommendations.

4.10 Water Treatment

If the condition of the water is such that constant bleed-off

will not control scale and/or control the recirculating water

pH level within the acceptable range listed below, chemical

treatment may be required. If a water treatment program

Figure 4-5. Belt Tensioning Schematic