3. To detach the left-hand side of the terminal block,

position the flat blade underneath the terminal

block to the left, and push down the screwdriver

handle. When you do this, you are using the

screwdriver as a lever to pry up the terminal block.

4. To detach the right-hand side of the terminal block,

position the flat blade underneath the terminal

block to the right, and push down the screwdriver

handle.

5. If necessary, repeat steps 3 and 4 until the terminal

block is removed.

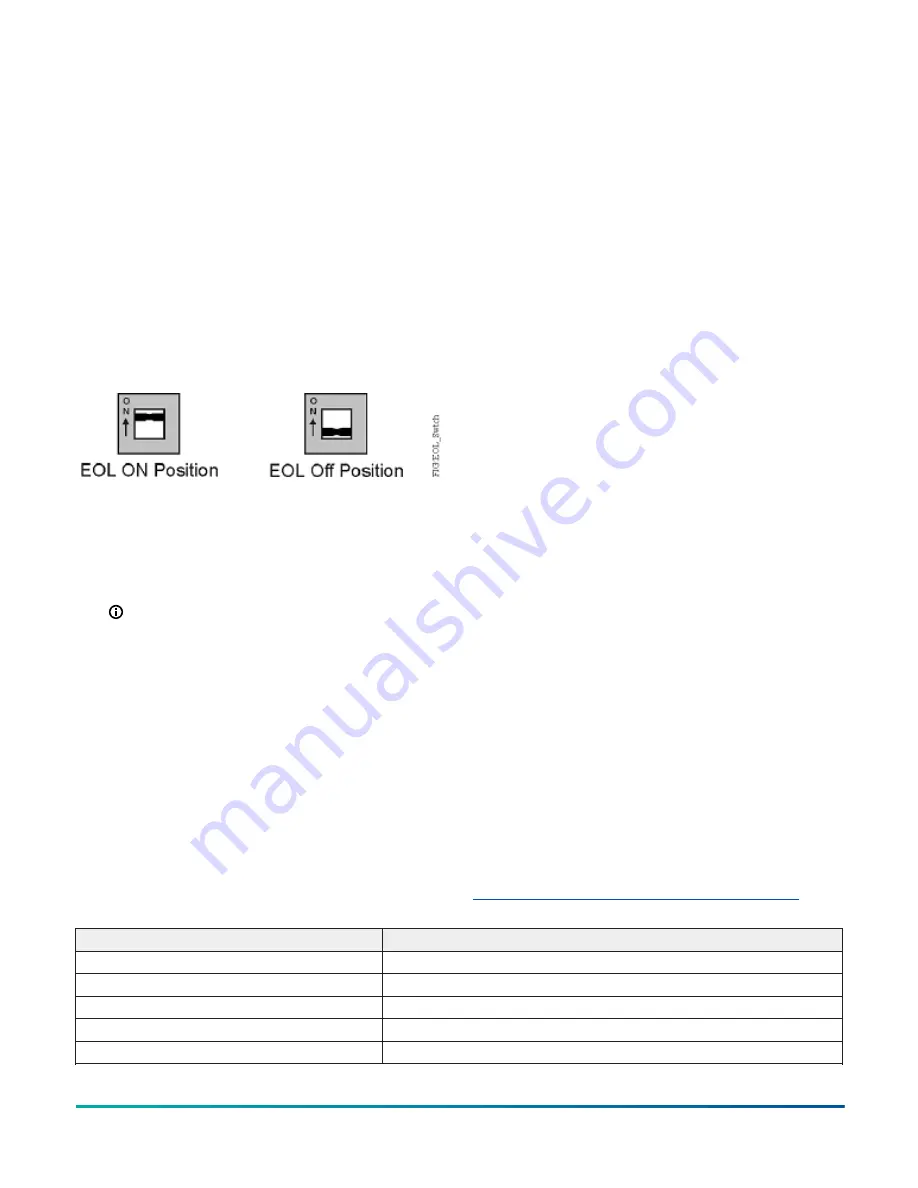

Setting the End-of-Line (EOL) switch

Each CVM controller has an EOL switch, which, when

set to ON (up), sets the CVM controller as a terminating

device on the bus. See

location. The default EOL switch position is OFF (down).

Figure 12: End-of-Line Switch Positions

To set the EOL switch on a CVM controller, complete the

following steps:

1. Determine the physical location of the controller on

the FC bus.

2. Determine if the controller must be set as a

terminating device on the bus.

Note:

For detailed information about EOL

termination rules and EOL switch settings on

FC buses, refer to the

MSTP Communications Bus

Technical Bulletin (LIT-12011034)

.

3. If the controller is a terminating device on the FC

Bus, set the EOL switch to ON. If the controller is not

a terminating device on the bus, set the EOL switch

to OFF.

When a controller is connected to power with its EOL

switch set to ON, the amber EOL LED on the controller

cover is illuminated.

Input and output wiring validation

The CVM controllers ship with a cooling only, warm or

cool adjust application loaded by default. You can use this

default application to perform wiring verification using

the MAP Gateway or the MS-DIS1710-0 local controller

display.

To perform wiring validation, ensure that you set the

rotary switches to the desired address and wire the input

and output terminals. Apply power to the CVM controller.

The Fault LED behaves the same as it does during normal

application load. When the Fault LED turns off, connect

to the device with either a MAP Gateway or MS-DIS1710-0

Local Display to view the points in the controller.

Commissioning equipment controllers

To commission the CVM03050 controller, use the following

procedure:

1. With the desired application loaded in the controller,

commission the VAV Box. Refer to the

Controller Tool

Help (LIT-12011147)

.

2. Perform airflow balancing on the VAV box.

Refer to the

VAV Balancing Tool Technical Bulletin

(LIT-12011087)

.

3. Perform commissioning checkout procedures. Refer

to the

Controller Tool Help (LIT-12011147)

.

You commision MS/TP equipment controllers with the

CCT software using either MAP Gateway, a ZFR wireless

dongle, or in passthrough mode. When the controller

is configured to use the N2 protocol, you must use the

MAP Gateway at the SA Bus. Wireless connections are not

supported in N2 mode. These connection options require

additional hardware listed in Table 13.

Firmware package file

The MS-FCP-0 equipment controller firmware package

files are required for CCT to configure and commission

the controllers. The firmware package files also allow you

to upgrade an existing controller to the latest firmware

release available for that controller.

Beginning at CCT Release 13, the firmware package files

are orderable separately; they are not included with CCT.

They are obtained from the

Metasys

software licensing

portal, and are loaded and licensed on the computer/

server that is running CCT.

For additional information about the firmware

package files, refer to the

CCT Installation Instructions

(LIT-12011259)

.

Setting a preloaded application

You can configure a CVM controller to use one of the

14 preloaded applications using the MAP Gateway

release 5.1 or later. Refer to Table 9 for the list of

preloaded applications. The CVM controllers ship with the

Cooling Only W/C Adjust application set by default. For

instructions on setting a different preloaded application

using the MAP Gateway, refer to the uLearn training video

Setting a CVM Preloaded Application using the MAP

Table 9: CVM Preloaded Standard Applications

Application Name

Description

Cooling Only W/C Adj

Single Duct Cooling Only, Warm/Cool Adjust

Cooling Only SP Adj

Single Duct Cooling Only, Setpoint Adjust

Incr HW Reheat W/C Adj

Single Duct Incremental Hot Water Reheat, Warm/Cool Adjust

Incr HW Reheat SP Adj

Single Duct Incremental Hot Water Reheat, Setpoint Adjust

Elec Reheat 3 Stg W/C Adj

Single Duct Electric Staged Reheat, 3 Stages, Warm/Cool Adjust

M4-CVM VAV Box Controllers Installation Guide

15