Installation, Operation & Maintenance Instructions

5

API PLAN 74 STEAM

SEAL SYSTEMS - STEAM

•

Check the condition of the steam traps (see Section 7.2).

•

Barrier pressure. Compare with the operating pressure on the

nameplate.

•

Condition of alarm signals (see Section 7.3)

7.2 Steam traps

Steam traps have a finite life, the duration of which is determined by the

quantity of condensate to be released from the system. If a steam trap

has reached the end of its life, it will no longer operate, and condensate

will begin to build up in the system.

To check the operation, visually check for signs that condensate is being

released, and then slightly crack open the manual steam drain valve. If

condensate is released, this indicates that the steam trap is no longer

operating and liquid is building up inside the system. The steam trap(s)

should then be replaced at the earliest opportunity.

While operating the manual drain, the system is

pressurized with high temperature steam. Correct PPE

must be worn, the drain must be directed to a safe

location for the release of hot steam, and the valve

should be opened by the absolute minimum to reduce

the quantity of steam released, for personnel safety,

and to prevent a loss of pressure in the Plan 74 Steam

control panel.

It is recommended that the steam traps are checked after the first month

of operation and thereafter at monthly intervals.

Irrespective of visual condition, it is recommended that the steam traps

are replaced annually.

7.3 Signals and alarms

The instrumentation on the system has the specific purpose of signalling

eventual malfunction of the mechanical seals. Possible alarm signals

indicating a malfunction are as shown in Table 2.

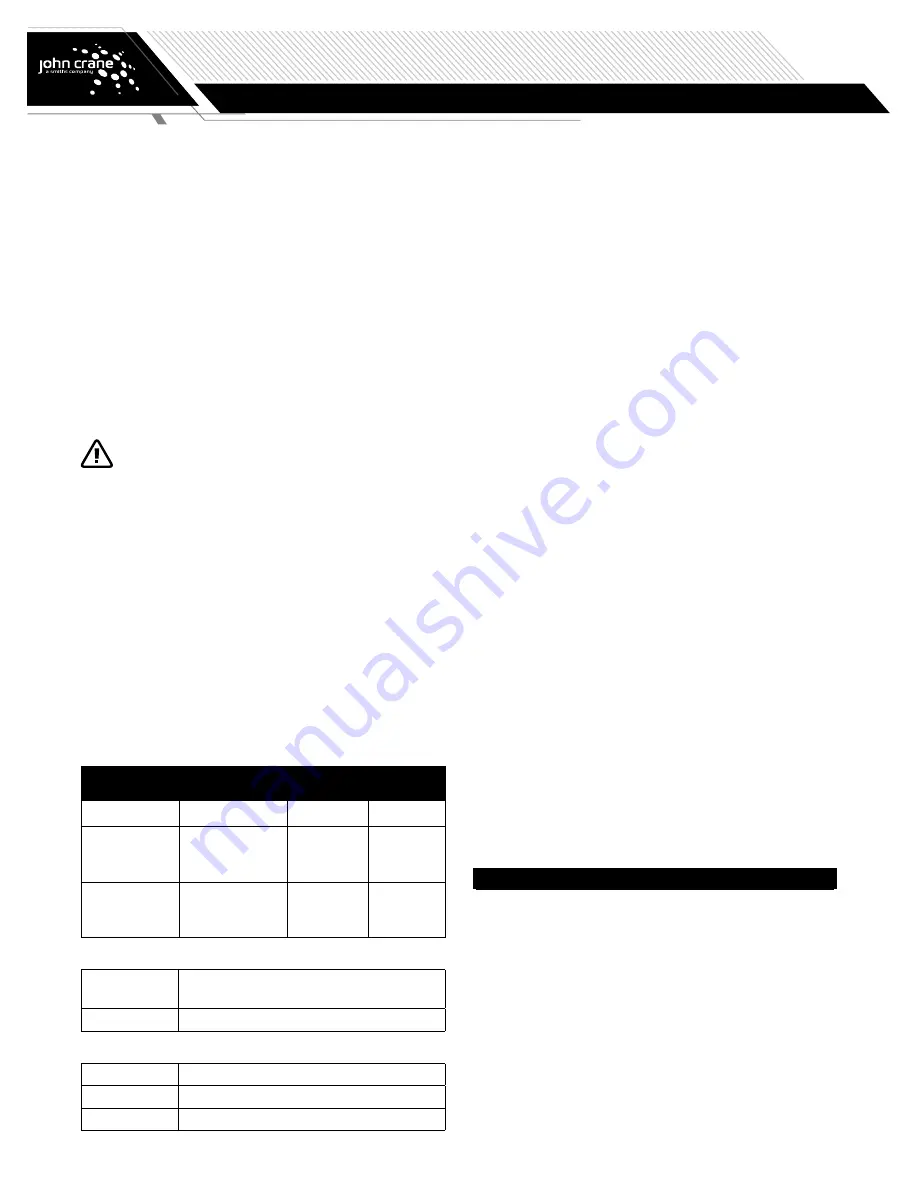

TABLE 2. Possible Alarm Signals Indicating a Malfunction

Effect

Instrument

Action

Cause

Falling Pressure

Pressure Gauge (PG)

or Pressure Indicating

Transmitter (PIT)

A

C to E

Low Pressure/

Shutdown Required

Pressure Indicating

Transmitter (PIT) or

Pressure Switch (PS)

B

C to E

Actions

A

Investigate cause and monitor to ensure values do not breach

safe limits

B

Shut down machine to prevent damage or loss of containment

Causes

C

Excessive leakage across the inboard seal or outboard seal

D

Pipe work/joint failure

E

Drop in the barrier gas supply pressure/flow

The signal from the pressure transmitter can be used either:

•

LOCALLY (with a Klaxon and/or beacon)

•

REMOTELY (in the control room)

Consult the specific instrument manufacturers manual should there be a

malfunction.

If necessary for safety, the alarm signals could be used as a

trip function.

7.4 Instrument maintenance

All instruments require regular calibration, following local processes

and regulations. See the supplier's instruction manual for and additional

instructions for maintenance of electrical instruments.

7.5 Spare parts

Spare parts must conform to the established technical specifications of the

manufacturer. This is guaranteed with John Crane spare parts.

You are advised to stock the most important wear parts on site.

The following data is necessary for spare part orders:

•

John Crane code/part number

•

John Crane order/ref no.

•

Part description

•

Quantity

7.6 Annual maintenance checks

Disconnection shall be made by plant person in charge of authorization.

Before any maintenance operation the system, the machine must be

stopped and depressurized, the barrier pressure must be fully discharged,

and the equipment allowed to cool to ambient temperature.

A suitable container should be available to contain any liquid drained

from the barrier system.

All parts requiring maintenance must be thoroughly decontaminated prior

to any work commencing.

All joints should be checked for tightness and signs of steam barrier

leakage. If present, all flange joints should be checked for tightness and,

if necessary, gaskets changed using replacements available from John

Crane.

8. Accompanying Documents

Installation Drawing (job specific) or Typical Drawing and Operational

Data Sheet.

A name and data plate is fitted to each Plan 74 Steam control panel.

It contains references and part numbers which must be quoted in any

communication.

For replacement parts please contact your local John Crane

office, quoting the system code number.