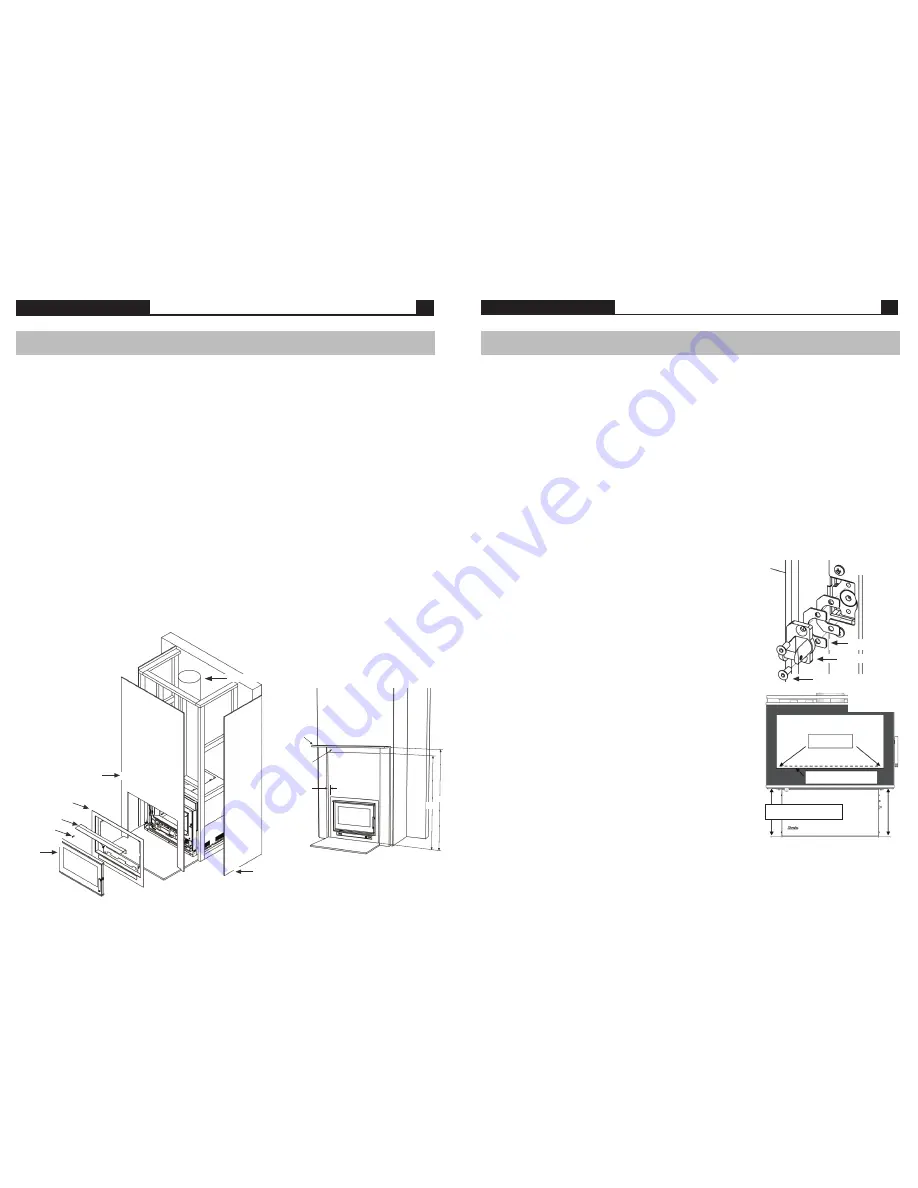

Door

Removable fascia

9mm cement sheet,

villaboard, Bellis Board

or equivalent

Tripleskin flue

Plaster,

timber,

MDF etc.

Mantle only

hot air deflector

M8 cap screw

Figure 4

Tilga Insert

6

Tilga Insert

11

Installation

(Continued)

Maintaining & Servicing your Jindara

Cleaning your flue (It is recommended that you seek the services of a licensed plumber to carry out flue maintenance).

Firstly and carefully remove cast iron plates and baffle system and put to one side. Close the heater door. Obtain a 150mm

flue brush from your local Jindara Dealer and proceed up onto the roof. Remove the cowl. Slowly push the brush down

the chimney until it stops. Pull the brush back out and repeat the process.

Each time you do this you will notice that the brush will go further down the chimney until it reaches the bottom.

The soot and creosote will fall down the chimney and into the firebox. Clean residue from firebox. Replace the baffle plate

first, followed by the cast iron liners.

Make sure you do the job well. The cleaner the flue the less chance there will be of the creosote sticking again.

After you replace the cowl, inspect the roof flashing for any damage that may have incurred whilst you were

cleaning the flue. Reseal the seal on the roof with roof and gutter silicon if required.

Cleaning the glass

Generally the only time you will possibly need to clean your glass is after a long overnight burn. If you find that you have

a wet sticky black film on your glass (creosote), it is better to burn the heater as normal for one load of wood. When the

wood has burnt down to a hot bed of embers, open the door and leave it wide open until the glass cools sufficiently to

be wiped with a damp cloth. This should clean all the white smoky film off the glass. Creosote on the glass is normally a

sign that you have tried to get too long an overnight burn or you have burnt excessively wet or green wood. If the film on

the glass won’t come off with a wet cloth, you can use wet ash from the ash bed as a cleaner or commercial products

such as Crystal Clear, Johnson Foam Clean or Windex.

ZCC Installation notes

The Jindara Tilga has been factory fitted and attached inside the ZCC. Depending on your desired installation type, whether

it be at ground level, or elevated for a mid-wall installation, the following sequence of installation steps may need to be adjusted

to suit.

• Select the position that you wish to install your Jindara Tilga Insert ZCC, carefully allowing for flue clearances of 305mm in the

roof cavity (the outer flue being 255mm requires a 25mm clearance on either side to combustibles, making overall clearance of

305mm), and allowing for sufficient clearances for combustibles where rear and side walls may play a role in the installation

process.

• Ensure there is access to a power supply inside the enclosure for connecting the fan in the heater. In some instances an

extension cord maybe required to reach a power supply. Please keep in mind that the fan will need to be removed for cleaning,

and access to the power supply should be made relatively easy.

• Remove door (open door handle and swing door open to roughly 45deg and lift off hinge), remove cast iron liners and baffle

system from inside the firebox to reduce overall weight of unit.

• Using a 5mm allen key, remove x4 M8 cap screws which attach the fascia to the firebox. Carefullly remove the fascia and place

to the side. Removing the fascia allows the ZCC to be mounted flush with the front of the enclosure face for a flush fascia finish.

• If installing at ground level onto a combustible floor surface, place required floor protector under the desired position of the

ZCC than carefully lift the ZCC into position.

• Fit flue system to upstands and appliance. Install through roof as per flue manufactur’s instructions, and terminate at the

required height above the roof line, fit cowl. Note: the base of the active flue will need to be trimmed and sealed with fire cement.

• Build your frame around the ZCC maintaining the clearances listed previously.

• Enclose the front of the frame with minimum 9mm non-combustible cement sheet, villaboard, bellis board, etc.

• Enclose the sides of the frame with plaster, timber, MDF, etc.

• Install the mantle if required as per mantle clearances on page 6.

Note: If mantle is made out of combustible material, the Jindara Tilga must have it’s hot air deflector attached to the fasica.

• Re-attach removable fascia & door.

55mm

(appliance to

mantle upright)

Breast plate no

thicker than

30mm

Mantle max

250mm

1500

1410

Catch Assembly

Latch Shim/s

Retaining Screws

To maintain an efficient and safe use of your Jindara Tilga, you may need to adjust

the door hinge and catch to ensure the door closes safely and correctly over the

duration of its life.

Adjusting door catch

• Open door to gain access to catch.

• Using a 3mm Allen key, remove the two catch retaining screws and set aside.

• To tighten the latch, remove one shim. To loosen the latch, fit an additional shim.

• Additional shims are provided in the user manual packaging. Refer to figure 11-1.

• Once the desired setting has been achieved, re-fit the catch assembly using the

two retaining screws.

• Note that if an adequate seal cannot be achieved through the removal of one

shim, a replacement door rope may be required.

Ash Lip Edges

Align With Glass Edge

Measure Height To Door

Adjusting door hinge

The door hinge defines the door alignment to the heater and the door catch,

as well as determining the amount of pressure applied to the main door rope

at the hinge side of the door.

To align door:

• Slightly loosen 3 x M8 Bolts securing the hinge to the heater. The upper bolts should

be loosened 1- 1+1/2 turns, while the lower bolt should only be loosened 1/2 a turn.

• Align door horizontally by pivoting the door about the lower bolt. Note that there is

no provision for lateral adjustment of the door hinge position.

• Check the alignment of the door by measuring vertically from the underside of the

door at each outer edge, to the base of the unit, as per figure 11-2. This measurement

should be taken with the hinge bolts tightened and with the door hanging under

its own weight.

To adjust hinge shims:

• Open door and lift free of hinge, and place on a soft flat surface while

servicing the hinge.

• Remove the door hinge and fasteners as shown in figure 13.

• Remove x1 hinge shim plate in order to tighten the seal of the door rope. The maximum number of shims permitted

behind the hinge is 2, fitted as standard.

• Fit door and re-align door to catch and firebox before fully tightening M8 bolts.

Figure 11-1

Figure 11-2