CLEANNING:

It is recommended to use any cleaner without acid base formulation to clean all sanitary applian-

ces connected to the unit and the lifting station. Lo prevent lime deposit, it is recommended to, on a regular

basis, disconnect from the power net the lifting station, pour a mixture of 1 litre of vinegar and 3 litres of water

(aprox.) through any connected sanitary appliance (washbasin, sink, etc), leave it act some hours, connect the

lifting station and switch it back on.

PROBLEM SOLUTION:

Verify that the connected elements work correctly and do not have leakages, check that

the lifting station is correctly switched on its base and this base has power supply. Check the motor heat protec-

tion has not acted (by waiting 20 minutes aprox. the unit should reset itself automatically).

MAINTENANCE AND INSTRUCTION MANUAL - 7

English

EB-705 LIFTING STATION

PROBLEM

CAUSE

SOLUTION

- The lifting station does not start

- It is disconnected.

- The electricity supply is not the correct one.

- The electrical protection has been activated.

- Connect the appliance correctly.

- Check the electrical connection.

- Wait about 20 minutes until the motor cools.

- The differential switch trips

- The motor’s earth connection is defective.

- Motor is broken. Contact Technical Assistance

- The motor works but it does not discharge or it

does so slowly.

- Blockage in the drainage pipe

- Clean the drainage pipe

- The motor buzzes but does not turn

- Turbine blocked by foreign matter.

- Disassembly the caset. Contact Technical

Assistance.

- After draining, the motor starts up and stops

indiscriminately.

- Leak from the non-return valve, loss of water

from one of the connected sanitary fixtures

- Clean the discharge pipe’s non-return valve.

- Check and replace the joints of the taps of the

connected sanitary fixtures

- The motor does not stop

- Excess height or length of the drainage pipe.

- Loss of power because of too many elbows.

- Blockage in the discharge pipe.

- Obstruction of the drainage pipes due to

limescale.

- Malfunction of the microswitch.

- Reconsider the drainage installation.

- Reconsider the drainage installation.

- Clean the discharge pipe.

( G6)

- Carry out the descaling process.

- Contact Technical Assistance

- The motor does not work with the water of one of

the sanitary fixtures connected.

- The auxiliary connections are obstructed or the

non-return valve is blocked.

- Lack of aeration or gradient in the auxiliary

connection.

- Malfunction of the microswitch.

- Clean the auxiliary connection section of pipe.

- Provide the installation with secondary ventilation,

or install an aeration valve (Jimten A-69 type). /

Reconsider the installation.

- Contact Technical Assistance

- After draining, the motor starts up repeatedly

before stopping for good

- Water returning to the lifting station. The non-

return valve does not work properly

- Carry out a number of discharges with clean

water and clean the non-return valve.

(D1)

- Water returns to the shower basin.

- The minimum necessary gradient has not been

allowed for in the drainage installation. (See

shower basin height)

- Malfunction of the auxiliary connection’s non-

return valves.

- Reconsider the installation (raising the height of

the shower basin).

- Cleaning and/or replacement of the side connec-

tion’s non-return valve.

(G6A, G6B)

- Strange noise when the motor is working

- Obstruction/blockage because foreign matter has

fallen into the unit.

- Extract the matter from inside the unit.

- Smells come from the lifting station

- Wear of the active carbon filter.

- Replacement of the filter (Contact Technical

Assistance).

- The shower basin does not drain well

- Possible obstruction of the drain.

- Siphonic shower basin drain, creates plunging of

air during drainage

- Cleaning of the drainage piping.

- Remove the siphon from the shower basin valve

For widespread version of this manual, visit www.jimten.com

Summary of Contents for Ciclon Series

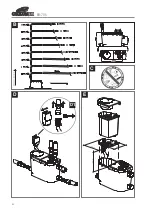

Page 2: ...1 2 EB 705 D E B C 2 D1...

Page 3: ...3 EB 705 G F F1 F2 F3...