14 of 17

7.

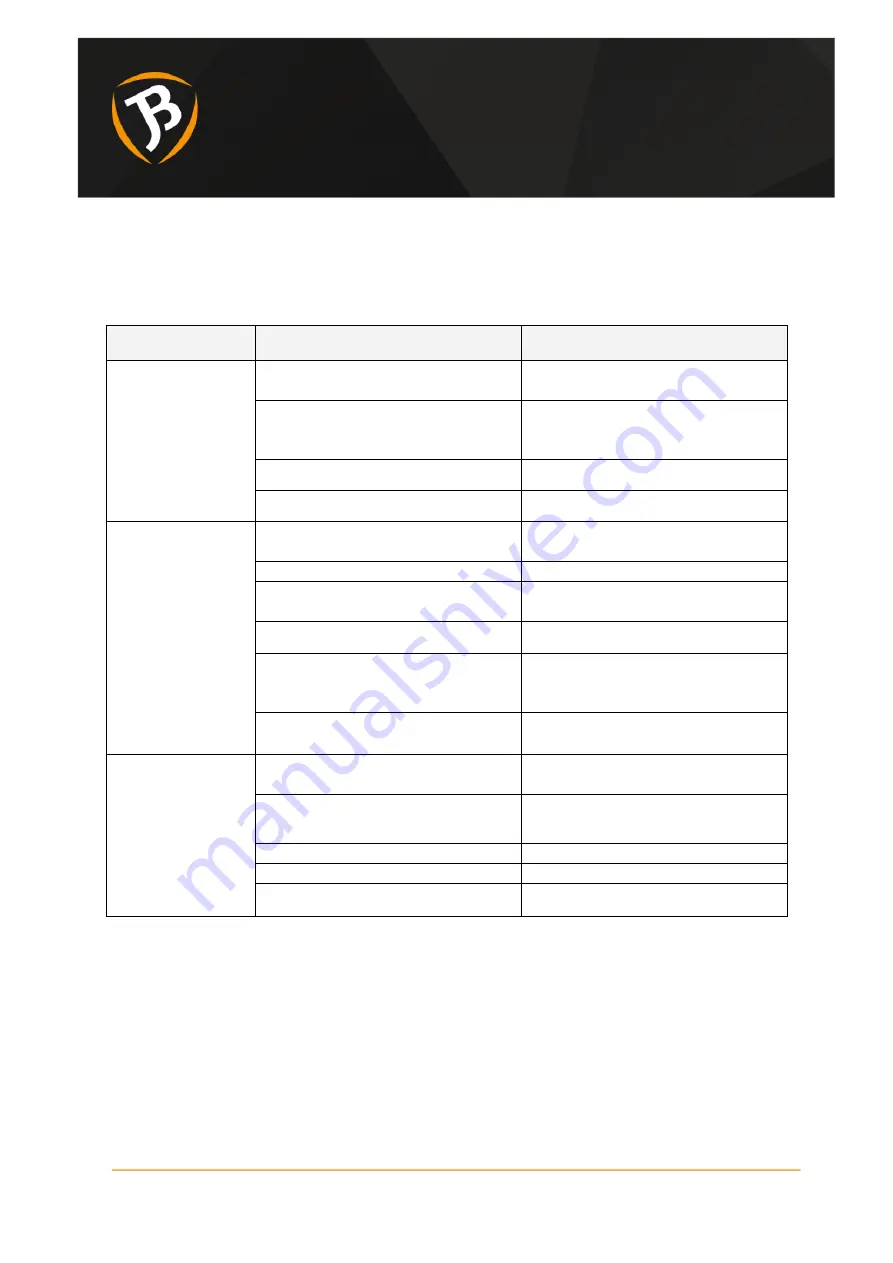

MALFUNCTION-CAUSE-REMEDY

Malfunction

Possible Cause

Remedy

•

Low flow, Low

Pressure

Incorrect blower rotation

Check and correct blower rotation if

required

Dirty or contaminated filters

These items MUST be changed regularly

(maximum of 6 months) dependant on

amount of use

Damaged hose lining

Replace damaged hose

Air leaks in system

Check / replace damaged hose and clips

•

Electrical

Overloading

Blower not piped to system correctly

Only run blower when connected to the

operating system. Never run in isolation.

Motor has winding or bearing damage

Contact

supplier

immediately

Electrical supply problems

Ensure that supply voltages match with

the motor rating plate details

Leak in air delivery ducting

Replace any damaged ducting

Blockage in air delivery ducting

Check all ducting and air delivery devices

for blockages/damage. Replace as

necessary.

Build-up of dust on the impeller blades

Clean dust from impeller blades.

•

Irregular/Excessive

Noise

Bolts loose on blower/motor assembly

Regular maintenance and

checking/tightening all bolts

Motor mounts loose

Regular maintenance and

checking/tightening all mounts

Motor bearings worn

Contact supplier immediately

Summary of Contents for JS-606 Series

Page 1: ...PERSONNEL CLEANING BOOTH EXTRACTOR ACM 0002 Issue 3...

Page 8: ...8 of 17...

Page 9: ...9 of 17...