13

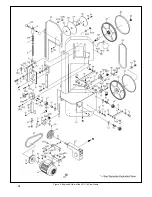

1. To remove the blade, place the saw frame in the rearmost position by pushing down

on the saw frame release lever (Figure 3 Item 2) and lock it by turning the saw frame

release knob (Figure 3 Item 1.2) clockwise.

2. Remove the panel on the base to expose the lower blade wheel.

3. Open the panel on the saw head to expose the upper blade wheel.

4. Remove the blade safety guard.

5. Turn the blade tension handle (Figure 3 Item 3) counterclockwise until the blade

hangs loose.

6. Use leather gloves to prevent cuts and scratches. Pull the blade off the drive wheels

and out of the blade guides. Store the removed blade carefully before proceeding.

7. To install the blade, slide the new blade into the blade guides.

8. Place the blade over the bottom wheel.

9. Place the blade over the top wheel. The teeth must point down toward the table.

10. Push the blade so it is seated against the shoulders of the wheels.

11. Turn the blade tension handle clockwise enough to hold the blade firmly in place.

12. Reconnect the saw to its electrical power source.

13. Turn the machine on to allow the blade to position itself. Check and adjust the

tracking of the blade. Refer to Blade Tracking Adjustments in this manual.

14. Turn the blade tension handle clockwise to finish tightening the blade. Do not over-

tighten the blade; tighten it just enough so it does not slip while cutting.

15. Install the wheel guards and blade covers.

The most common causes of your band saw not cutting straight are:

1. Blade tension is set to low.

2. The blade is either dull or worn on one side.

3. The blade is upside down. The teeth must point down toward the

table.

Blade Break-In Procedures

New blades are very sharp and, therefore, have a tooth geometry that is easily damaged

if a careful break-in procedure is not followed. Consult the blade manufacturer’s literature

for break-in of specific blades on specific materials. However, the following procedure will

be adequate for break-in of JET-supplied blades on lower alloy ferrous materials.

1. Clamp a section of round stock in the vise. The stock should be two inches or larger

in diameter.

2. Operate the saw at low speed. Start the cut with a very light feed rate.

3. When the saw has completed about 1/3 of the cut, increase the feed rate slightly and

allow the saw to complete the cut.

4. Keep the feed rate at the same setting and begin a second cut on the same or similar

work piece.

5. When the saw has completed about 1/3 of the cut, increase the feed rate while

watching the chip formation until cutting is at its most efficient rate (refer to Evaluating

Cutting Efficiency in this manual). Allow the saw to complete the cut.

6. The blade is now considered ready for use.

Controlling the Cut

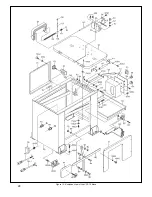

Hydraulic Feed Control

The weight of the saw frame provides the force needed to cut through the work piece.

The saw has a hydraulic cylinder that controls the feed rate.

The hydraulic feed control circuit consists of a single-acting hydraulic cylinder and a flow-

control valve. The feed control cylinder resists motion in the forward direction to control