28

Abrasive Selection Guide

Grit Common

Application

24........ Abrasive planing, surfacing rough-sawn boards, maximum stock removal, glue removal.

36........ Abrasive planing, surfacing rough-sawn boards, maximum stock removal, glue removal.

50........ Surfacing and dimensioning boards, trueing warped boards

60........ Surfacing and dimensioning boards, trueing warped boards.

80........ Light dimensioning, removal of planer ripples.

100...... Light surfacing, removal of planer ripples.

120...... Light surfacing, minimal stock removal.

150...... Finish sanding, minimal stock removal.

180...... Finish sanding only, not for stock removal.

220 ..... Finish sanding only, not for stock removal.

Abrasives

The abrasive material you choose will have a

substantial effect on the performance of your

sander. Variations in paper type, weight, coating

and durability all contribute to achieving your

desired finish.

JET Abrasives are available in Ready-To-

Wrap

TM

pre-cut lengths or in the convenient

Ready-To-Cut pre-marked box. Your JET dealer

can recommend the best choice for your

application.

Selecting Drum Abrasives

It is important to select the proper grit of

abrasive for the type of sanding being performed

to achieve maximum results. As with any

sanding operation, first begin sanding with a

coarser grit, depending upon the roughness of

the stock or the amount of stock to be removed.

Then progressively work toward finer grits. The

chart (Figure 44) shows the general uses for the

various grits. JET offers abrasives in the ten

different grits shown – consult the stock

numbers on page 32 to order.

The amount of stock to be removed is a major

consideration when choosing the grit grade with

which to begin. Grits 24, 36, 50 and 60 are

primarily designed for stock removal. Grits 24

and 36 will remove the most material in one

pass, whether you are doing abrasive planing,

cleaning up glued panels, or flattening stock.

Grits from 100 through 220 are primarily

finishing grits designed to remove the scratch

pattern from the previous grit used. For best

results, never skip more than one grit grade

when progressing through a sanding sequence.

For fine work, such as furniture, try not to skip

any grit grades during the sanding process.

In general, premium quality abrasives will

produce a better finish with a less noticeable

scratch pattern.

NOTE: Grits that are too fine can sometimes

burnish the wood and leave a glossy surface

which will not accept stains evenly. This will vary

by type of wood. Oak, for example, is

susceptible to burnishing because of its open

pores.

Cleaning Abrasive Strips

Regularly clean the abrasive strips on the drums

with commercially available cleaning sticks,

following the manufacturer’s directions. When

cleaning, also brush the stick crumbs from the

drum while it is still rotating.

In some cases, build-ups resulting from burns

can also be removed with Plexiglas held on

edge over the rotating drum.

Always wear eye protection

while performing sandpaper cleaning, and

take all precautions to avoid any contact of

hands or clothing with the rotating drum.

Cloth-backed abrasives can be cleaned by

soaking in paint thinner or mineral spirits for 20

minutes to 1 hour, then using a brush to remove

any build-up. Dry the abrasive strips completely

before using. Any used solvents should be

discarded in compliance with environmental

regulations.

Increasing Abrasive Life

Abrasive life can be increased not only by

cleaning, but by removing the abrasive strip from

the drum and reversing it. To do this, remove the

strip and use what was the trailing end as the

starting end on the left (outboard) side of the

drum. Reversing the strip will provide a fresh set

of cutting edges on the abrasive.

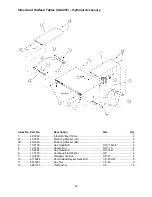

Figure 44

Summary of Contents for SandSmart 22-44 Pro

Page 34: ...34 Stand Assembly...

Page 36: ...36 Drum Head Assembly...

Page 38: ...38 Conveyor and Motor Assembly...

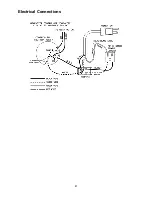

Page 41: ...41 Electrical Connections...

Page 42: ...42 NOTES...

Page 43: ...43...