13

7.9

Coolant flow

Coolant pump must be

submerged before operating to prevent damage

to pump.

The blade guides are fitted with coolant valves.

Coolant is provided to the fittings through

interconnecting tubing, and is dispensed directly

onto saw blade.

Adjust coolant flow valves atop blade guide brackets

to provide desired flow. The flow should be no more

than blade can draw into the workpiece by its

movement through the material.

The coolant flow can be stopped in two ways: Turn

off coolant pump switch on control panel, or close

coolant flow valves.

8.0

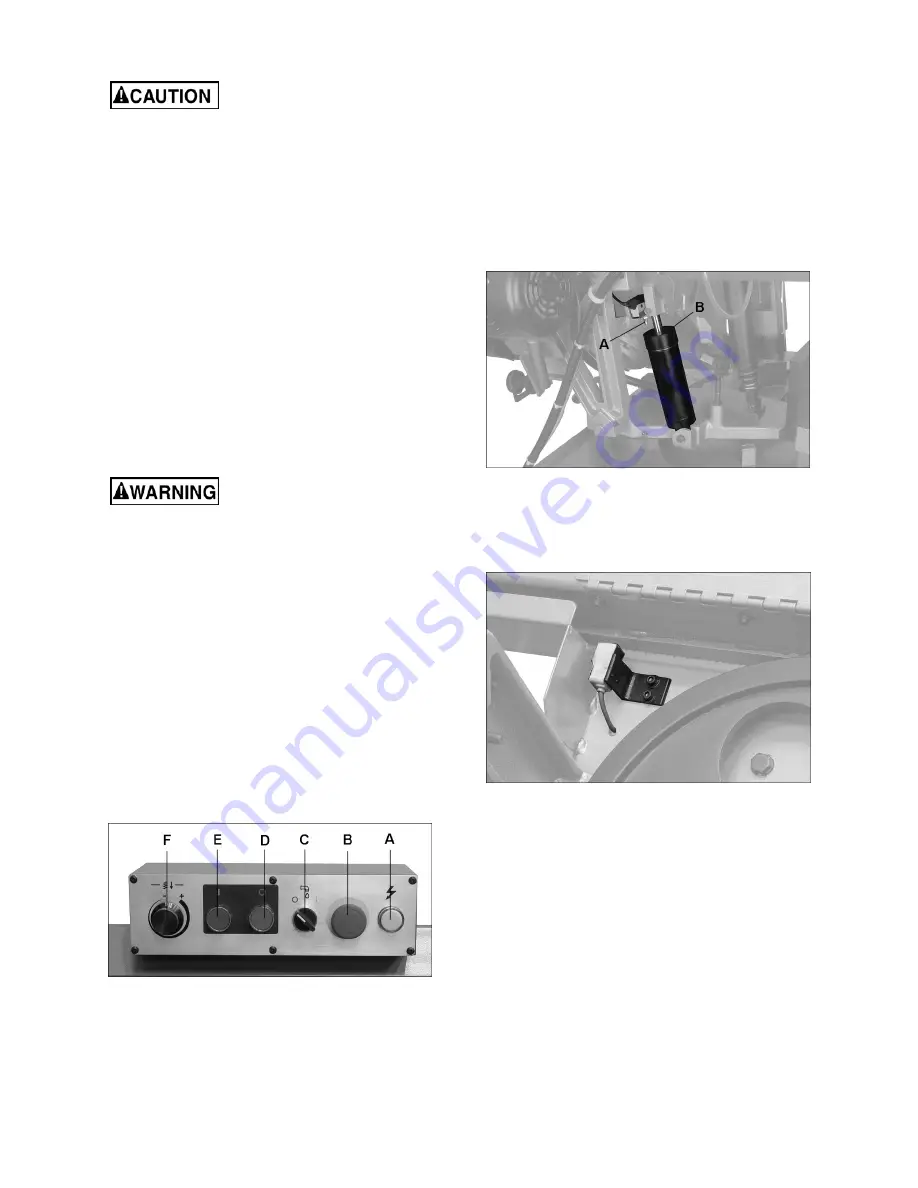

Control panel

Refer to Figure 8-1.

Power Indicator Light (A)

– illuminates whenever

machine is running.

If bulb is out, light will not be

on but machine may still have power.

Emergency Stop Button (B)

– Press to immediately

stop all machine functions. To restart machine,

rotate button clockwise until it disengages.

Coolant Switch (C)

– Turn arrow to “I” to turn on

coolant flow. Turn arrow to “O” to stop coolant flow.

Stop Button (D)

– Press to stop motor/blade.

Coolant will still flow.

Start Button (E)

– Press to start motor/blade.

Feed Rate Control (F)

– Sets amount of downward

force that is applied to saw blade. The feed rate is

proportional to opening of valve. Increasing valve

opening (counterclockwise) increases feed rate;

decreasing valve opening (clockwise) reduces feed

rate. When set to zero, bow is locked in raised

position.

Figure 8-1: control panel

9.0

Operation

9.1

Automatic shut-off

9.1.1

Cut completion

The machine and any accessories which are wired

into the electrical system are controlled by the start-

stop buttons. Saw will automatically shut off when

cut is completed. The limit switch (A, Figure 9-1),

contacts top of hydraulic cylinder (B) and

deactivates motor.

Figure 9-1: auto shut-off switch

9.1.2

Blade breakage

If blade breaks during operation, a sensor near drive

wheel will shut off the saw (Figure 9-2).

Figure 9-2: blade break sensor

9.2

Auxiliary coolant hose

The saw is equipped with auxiliary coolant hose and

spray nozzle. This can be used to direct greater

volume of coolant at workpiece, or for washing off

table area.

9.3

Prior to Operation

1. Check that blade tooth direction matches

diagram on blade guard, and blade guides are

properly set.

2. Check gauge to verify proper blade tension.

Make adjustments if needed.

3. Check to see that blade is properly seated on

wheels after applying correct tension.

Summary of Contents for MBS-1018-1

Page 18: ...18 12 1 1 MBS 1018 1 MBS 1018 3 Bow Assembly Exploded View...

Page 22: ...22 12 2 1 MBS 1018 1 MBS 1018 3 Base Assembly Exploded View...

Page 26: ...26 12 3 1 MBS 1018 1 MBS 1018 3 Electrical Box Assembly Exploded View...

Page 29: ...29 13 2 Wiring Diagram for MBS 1018 3...

Page 31: ...31 This page intentionally left blank...

Page 32: ...32 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...