7.5 Installing work holding

The faceplate

is used for tuning bowls. There are a number

of holes for mounting the workpiece. Thread the faceplate

onto the spindle in a clockwise direction, and tighten two

setscrews (E, Fig 30).

Fig 30

Remove the faceplate by loosening two set screws. Push in

the spindle lock and use the provided wrench on faceplate

flats.

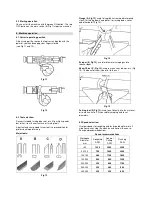

7.6 Adjusting tool rest

A 300mm tool rest is provided with your lathe. It is designed

to allow adjustment for height and position.

Loosen locking handle on tool rest base (G, Fig 31) to slide

base forward or back, and to angle it to the bed. Tighten

locking handle firmly before operating lathe.

Loosen handle (H) to raise or lower tool rest and angle it to

the work. Tighten handle before operating lathe.

Fig 31

Tool rest extension:

The extension (J, Fig 32) mounts to the tool rest base and

offers greater reach for the tool rest when turning off the bed

using the headstock at an angle, as shown.

Make sure the clamp bushings (K) are pulled apart sufficiently

to accept the post of the extension.

Fig 32

7.7 Adjusting tailstock

Turn the hand wheel (R, Fig 33) clockwise to move tailstock

spindle

forward. Lock tailstock spindle with the indexable

knob (Q).

Fig 33

The handle (P) locks the tailstock in position on the bed.

The live centre (S) can be ejected by turning the hand wheel

counter-clockwise.

The live centre pin can be removed to allow deep hole drilling

operations.

8. Maintenance and inspection

General notes:

Maintenance, cleaning and repair work may only be

carried out after the machine is protected against

accidental starting by pulling the mains plug.

Clean the machine regularly.

Inspect the proper function of the dust collection daily.

Defective safety devices must be replaces immediately.

Repair and maintenance work on the electrical system may

only be carried out by a qualified electrician.