14

Figure 17

8.12

Face plate: Installing/removing

1. Disconnect lathe from power source.

2. Mount the face plate to your workpiece.

3. Engage spindle lock pin.

4. Install face plate onto threads of headstock

spindle and rotate clockwise as far as it will go.

5. Face plate is now ready for turning.

6. To

remove

the face plate, engage spindle lock,

and turn face plate counterclockwise with face

plate wrench.

8.13

Checking center alignment

When the headstock is returned from outboard

position, the alignment between centers should be

checked.

1. Lock the headstock in normal spindle turning

position.

2. Slide the tailstock toward the headstock until

the centers almost touch (see Figure 18). Lock

the tailstock in position.

3. View the center points from top and side to

make sure they align.

4. If the centers do not align, unlock the headstock

and pivot it slightly. There should be enough

“play” in the headstock to adjust for this

alignment. Lock the headstock when finished.

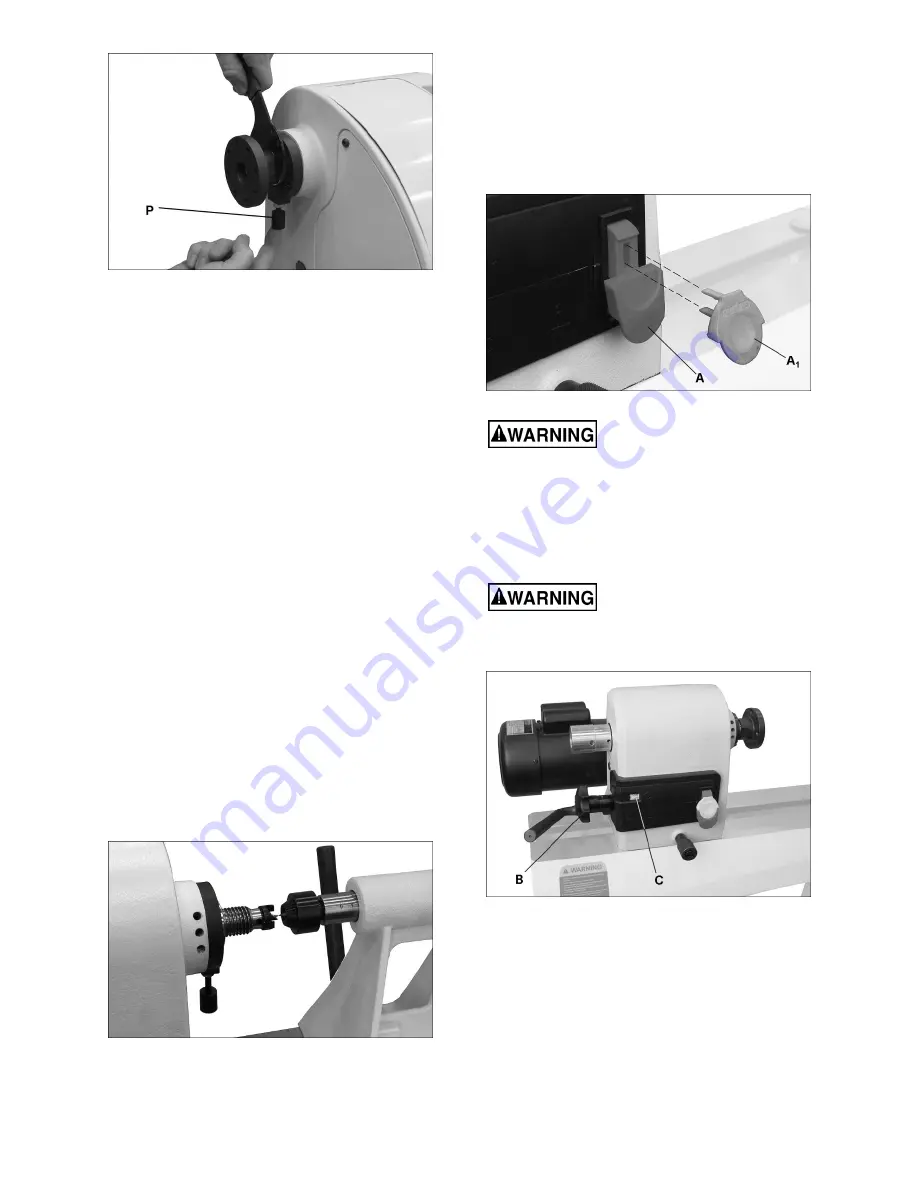

Figure 18

9.0

Operating controls

Refer to Figure 19.

On/off switch

(A): Pull to start lathe, push to stop.

The safety key (A

1

) can be removed to prevent

unauthorized use of lathe. The safety key must be

inserted to restart the lathe.

Figure 19

If a power outage should occur

during operation, the lathe will immediately

restart when power is resumed if the start switch

is still engaged. Push switch immediately to OFF

position in the event of a power outage.

Speed control handle:

Rotate handle (B, Figure

20) to set speed, which is displayed as RPM

(revolutions per minute) in the adjoining window (C).

Do not start lathe at maximum

speed when a workpiece is mounted in the lathe.

Start at lower speed and gradually increase to

desired speed.

Figure 20

The JWL-1440VS contains a Reeves or “split-

pulley” system.

As speed is increased, via the speed change

handle, the

spindle pulley

widens and the belt drops

down to the smaller diameter between the pulley

halves. Conversely, the

motor pulley,

which is

spring-loaded so that it adjusts automatically to the

movement of the spindle pulley, gets narrower,

drawing the belt outward toward the larger diameter.