12

Electrical Connections

All electrical connections must

be made by a qualified electrician! Failure to

comply may cause serious injury!

General Electrical Cautions

This machine must be grounded in accordance with

the National Electrical Code and local codes and

ordinances. This work should be done by a qualified

electrician. The machine must be grounded to protect

the user from electrical shock.

Wire Sizes

For circuits which are far away from

the electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords

according to the following table is recommended:

Conductor

Length

AWG Number

230/460 Volt Lines

120 Volt Lines

0 – 50 Ft.

No. 14

No. 14

50 – 100 Ft.

No. 14

No. 12

Over 100 Ft. No. 12

No. 8

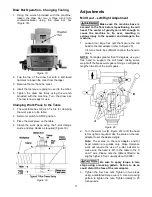

Figure 4

Confirm that power at the site matches power

requirements of the mill before connecting to the

power source.

The JTM-4VS has been pre-wired for 230 volt

operation. To change from 230V to the other voltage

offered, remove the junction box cover on the motor

and change the wires according to the diagram found

on the inside of the cover.

Before connecting to the power source, make sure

that the switch is in the off position.

The mill must be properly grounded.

Check for proper spindle rotation

in the high-speed

range

. The spindle should rotate clockwise when

viewed from the top of the machine. If the spindle

rotates counter-clockwise, disconnect from power

and switch two of the three power leads.

Lubrication

Do not operate the mill before

lubricating the machine fully. Failure to comply

may cause damage to the machine.

Refer to the

Maintenance/Lubrication

section and

make sure the machine has been fully lubricated

before operating.

Operating Instructions

Operating Controls

The lubrication system is a manually operated, one-

shot system requiring operator intervention. The

operator must lower the one-shot lever to lubricate

the machine ways and ball screws. The one-shot

lubrication system reservoir is located on the left side

of the machine.

The position of the milling machine mill head can be

set up to accommodate the work piece being

machined. The mill head can be set up for angles to

the left or right and for fore and aft angles. The mill

head can also be rotated on its turret. The ram can

be moved back and forth to reach work piece

locations at the fore and aft extremes of worktable

travel. Refer to the

Adjustments

section.

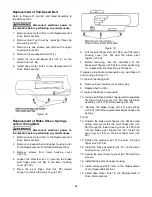

Motor Switch

The

Motor Switch

is on the upper left-hand side of the

mill head (Figure 5). The switch has three positions:

FWD (forward), STOP, and REV (reverse).

Setting the switch to FWD will provide clockwise

spindle rotation. Use FWD for normal, right-hand

tooling.

FWD (clockwise) operation occurs only when the

gearbox is in the low speed position. When the

gearbox is in high-speed position, the motor switch

must be in the REV position to provide right-hand or

clockwise rotation. Refer to Figure 6 for a chart of

required switch positions.

The motor switch controls a three-phase motor. The

motor can be switched from FWD to REV and back

with the motor running, and will reverse direction

when the switch setting is changed. At higher

speeds, this may put strain on the timing belt but

there will be no damage to the motor or gear

mechanism.

Figure 5

Summary of Contents for JTM-4VS

Page 10: ...10 JTM 4VS Dimensions Figure 2 Installation Diagram...

Page 11: ...11 JTM 4VS Overview and Terminology Figure 3 Overview...

Page 26: ...26 Head Assembly...

Page 30: ...30 Spindle Assembly...

Page 34: ...34 Base Assembly...