12

8.0

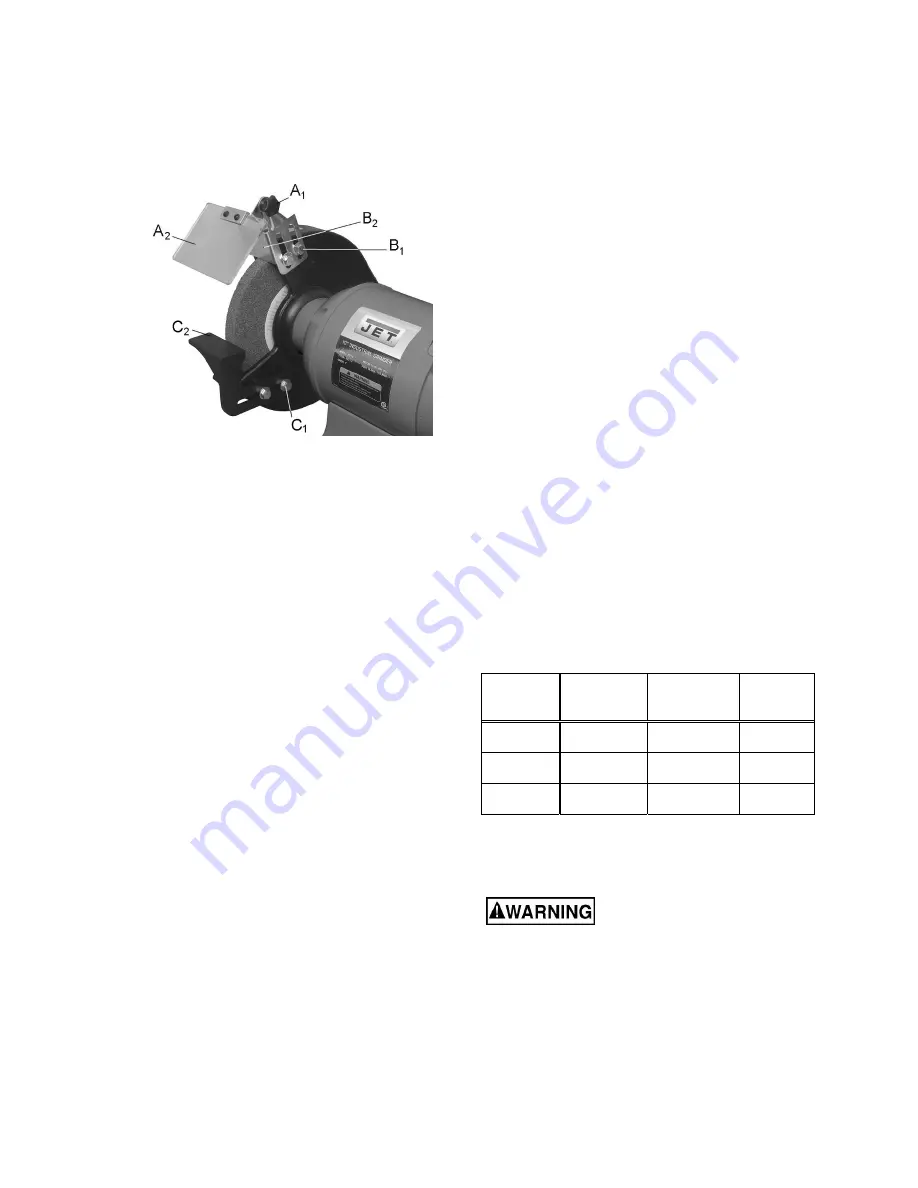

Adjustments

8.1

Eye Shield Tilt Adjustment

1. Loosen lock knob (A

1

, Figure 10).

2. Adjust eye shield (A

2

) to the desired tilt angle.

Figure 10: eye shield adjustment

8.2

Spark Guard

As the wheel wears down, the spark guards must

be re-adjusted to maintain a 1/16" distance.

Refer to Figure 10.

1. Loosen two hex cap screws (B

1

) with a 14mm

wrench.

2. Slide the spark guard (B

2

) to 1/16" distance

from the grinding wheel surface.

3. Tighten screws (B

1

).

8.3

Tool Rest

As the wheel wears down, the tool rests must be

re-adjusted to maintain a 1/16" distance.

Refer to Figure 10.

1. Loosen two hex cap screws (C

1

) with a 14mm

wrench.

2. Slide the tool rest (C

2

) to a distance of 1/16"

from the grinding wheel.

3. Tighten screws (C

1

).

9.0

Maintenance

For safety, turn the switch to OFF and remove plug

from the power source outlet before adjusting and

maintaining the bench grinder. If the power cord is

worn, cut or damaged in any way, have it replaced

immediately.

9.1

Ring Test

Before replacing a grinding wheel, perform this

simple test on the replacement wheel:

1. Loop a piece of string through the grinding

wheel hole and suspend the wheel by holding

up the string.

2. Tap the wheel with a piece of scrap wood or a

wooden dowel.

3. A good wheel will "ring"; a defective wheel will

"thud". Discard any wheel that does not "ring".

An internal defect may not be apparent by visual

inspection alone. The ring test may identify an

internal crack or void.

9.2

Care of Grinding Wheels

In normal use, grinding wheels may become

cracked, grooved, rounded at the edges, chipped,

out of true or loaded with foreign material.

Cracked wheels should be replaced

IMMEDIATELY. The other conditions can be

remedied with a dressing tool. New wheels

sometimes require dressing to make them round.

See

sect. 10.5.

9.3

Changing Wheels

The JET Series bench grinders come equipped

with general purpose grinding wheels. Wheels vary

according to types of abrasive, hardness, grit size,

and structure. Contact your local distributor for the

proper grinding wheel or wire wheel brush for your

application.

If you replace a wheel, obtain one with a safe rated

speed at least as high as the

NO

LOAD RPM

marked on the grinder's nameplate. Refer to Table

2 to determine correct dimensions for the

replacement wheel.

Model

Wheel

Diameter

Maximum

Width

Center

Hole

IBG-8

8" 1"

5/8"

IBG-10

10" 1" 1"

IBG-12

12” 2”

1-1/4”

Table 2

Your bench grinder will accept most polishing and

buffing wheels available at dealers and hardware

stores.

The use of any other

accessory is not recommended and may result

in serious injury!

To change a wheel

(see Figure 11)

:

1. Disconnect grinder from power source.

2. Loosen spark guard (B) and tool rest (C) and

move them away from the wheel.

3. Remove wheel guard using a cross-point or

flathead screwdriver.

Summary of Contents for IBG-8

Page 18: ...18 12 1 1 IBG 8 Grinder Exploded View...

Page 21: ...21 12 2 1 IBG 10 Grinder Exploded View...

Page 24: ...24 12 3 1 IBG 12 Grinder Exploded View...

Page 29: ...29 13 0 Electrical Connections 13 1 Wiring Diagram for IBG 8...

Page 30: ...30 13 2 Wiring Diagram for IBG 10...

Page 31: ...31 13 3 Wiring Diagram for IBG 12...

Page 33: ...33 This page intentionally left blank...

Page 34: ...34 This page intentionally left blank...

Page 35: ...35 This page intentionally left blank...

Page 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...