6

Fig 4

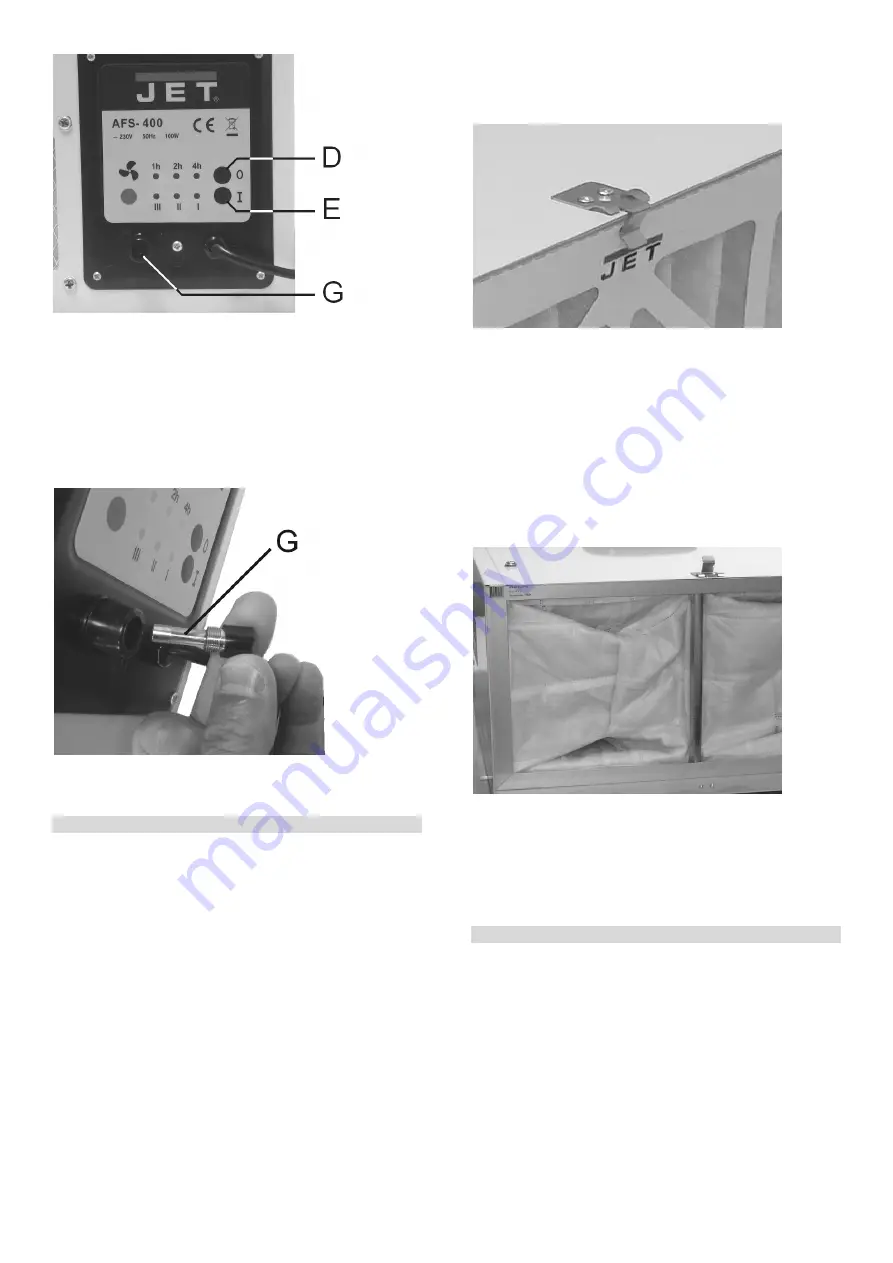

6.2 Overload protection

In case of overload, the motor control unit switches the unit

off. Wait 5 minutes to cool down and then re-start the unit.

The fuse (G, Fig 5) protects the electrical system in case of high

Amp-overload.

Fig 5

7. Maintenance and inspection

General notes:

Maintenance, cleaning and repair work may only be carried

out after the machine is protected against accidental starting

by pulling the mains plug.

Inspect the proper function of the air filtration system daily.

Replace clogged filters.

Clean the unit regularly.

Defective safety devices must be replaced immediately.

Repair and maintenance work on the electrical system may

only be carried out by a qualified electrician.

7.1 Changing Filters

Disconnect the machine from the power source.

During the changing or cleaning of the filters it’s necessary to

use a mask (mask with filtration).

There are two filters that need to be cleaned or changed.

The outer filter

can easily be removed by disengaging the two

clips (Fig 6).

Fig 6

Now you can simply pull the filter out, or carefully use a

screwdriver to pop the filter out.

Make sure the filter is inserted facing the proper direction

(JET-Logo visible)

The outer filter should be replaced depending on the amount

of usage and the environment of your shop.

The inner filter

can be pulled out of the unit (Fig 7).

Fig 7

The inner filter can be blown out with air (to be done outside

of building only!), or can be washed out.

8. Trouble shooting

Unit doesn’t start

*No electricity-

check mains and fuse.

*Defective switch, motor or cord-

consult an electrician.

*Motor overload protection has reacted-

Wait 5 minutes to cool down, re-start the unit.

*Overload fuse has blown-

Change the fuse.