19

10.10

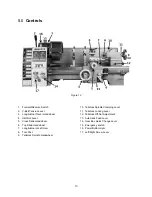

Four-way tool post

The four-way tool post is mounted on the top slide

and allows for tools to be clamped. Loosen the

center clamp handle to rotate any of the four tools

into position (Figure 29).

Use a minimum of two clamping screws when

installing a cutting tool.

10.11

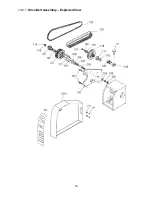

Change Gears

There are eleven gears (Figure 30, 2 pre-mounted

already) with different numbers of teeth (28, 30, 32,

38, 40, 44, 45, 46, 48, 52 and 56). They can be

combined for different speeds and feeds as

required. See chart on headstock.

11.0

Adjustment/replacement

11.1

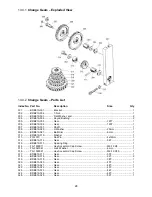

Adjustment of main spindle

bearings

The main spindle bearings are adjusted at the

factory. If end play becomes evident after

considerable use, the bearings may be adjusted.

Loosen setscrew (1, Figure 31) in the slotted nut (2,

Figure 31) on the back of the spindle. Tighten

slotted nut until all end play is taken up. The spindle

should still revolve freely.

Caution:

Excessive

tightening or preloading will damage the bearing

.

Re-tighten set screw (1, Figure 31).

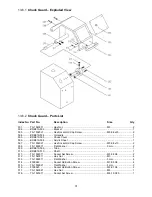

11.2

Adjustment of cross and top

slide

Each slide is fitted with a gib strip and can be

adjusted with screw (1, Figure 32) fitted with lock

nut (2, Figure 32). Loosen the lock nuts to adjust the

screws, and re-tighten lock nuts to secure the

setting.

Figure 32

Figure 29

Figure 30

Figure 31

Summary of Contents for 321370K

Page 25: ...25 13 2 1 Drive Belt Assembly Exploded View ...

Page 29: ...29 13 5 1 Electrical Exploded View ...

Page 32: ...32 13 7 1 Gear Box Exploded View ...

Page 35: ...35 13 8 1 Apron I Exploded View ...

Page 38: ...38 13 10 2 Saddle and Cross Slide Exploded View ...

Page 40: ...40 13 11 1 Compound Slide Exploded View ...

Page 42: ...42 13 12 1 Tailstock Exploded View ...

Page 46: ...46 13 15 1 BD 919 Bed Assembly Exploded View ...

Page 48: ...48 13 16 1 BDB 929 Bed Assembly Exploded View ...

Page 54: ...54 15 0 Speed and threading charts ...

Page 56: ...56 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...