Rubber track maintenance

C) Detachment of metal cores

The metal core functions as an adhesive for the rubber, especially between the core itself

and the steel cables. Detachment can be caused by excess track tension or by cable

breakage for the following reasons:

-

-

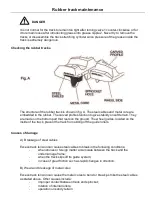

-metal cores have been rolled by a worn sprocket as

indicated in the figure. When this type of wear or

abrasion is encountered the sprocket must be

replaced as soon as possible.

This type of breakage, like that indicated in paragraghs A-B-C, leads to total functional

inefficiency and the track must be replaced.

D) Fatigue cracks and abrasion

1. Cracks at the base of the carved profiles are caused by fatigue due to rubber bending

caused by sprocket or the track-stretching wheel.

2. Cracks and bends on the edge of the rubber are caused

by maneuvering the track on concrete edges and curbs.

3. Cracks and abrasions in the rubber on the guide roller paths are caused by compression

fatigue of the rubber due to the weight of the wheel combined with operation on sandy

terrain or repeated sudden changes in direction.

4. Abrasion of the carved profile may be caused, in particular, by rotation on concrete or

gravel surfaces or hard surfaces.

Damage as indicated in paragraph D, points 1, 2 and 3, is not fatal for the track and the

track can continue to work even in the presence of gradual and progressive damage.

Continuation of the damage indicated at point 3 leads to exposure of the metal cores. If this

exposure extends for more than half of the circumference of the track then it is time to

replace the track, even though it can still be used.

E) Cracks caused by external factors

Cracks on the outside surface of the track (the surface in contact with the terrain) are often

due to contact with gravel, sharp stones, sharp materials such as sheet metal, nails, glass.

This type of damage is inevitable given the very nature of rubber itself, although the entity

depends on how the track used.

Cracks on the inside surface of the circumference and on the edge of the rubber are caused

by contact between track and the undercarriage structure or with sharp concrete edges.

Even though it does not look very good the track can still be subjected to severe working

conditions.