3

Product specific safety precautions

This equipment is designed be operated by qualified personnel. It should only be operated after

reading and understanding the safety warnings and operating procedures in this instruction manual.

1.

Do not smoke near this equipment.

2.

Firework is strictly prohibited during operation, keep away from heat, high voltage, flammable

and explosive place

3.

Use in a well ventilated area.

4.

When leaks are found in the equipment or hoses, immediately turn the air pressure off and repair

the leaks.

5.

Once leakage is found in the hose or other components during operation, turn off air compressor

immediately, conduct a detailed inspection and proceed with troubleshooting.

6.

Do not exceed the recommended operating air pressure. This could damage equipment. See

specification on Page 5.

7.

Keep a type ABC fire extinguisher nearby in case of fires.

8.

Always protect your skin and eyes from contact with oil and solvents.

9.

Do not start engine during the time of oil extraction. Otherwise it will cause the damage of

extraction probes and injuries of people.

10.

Be careful for the oil extracted out from the vehicle, as temperature of oil is high, always between

40~60

℃

11.

Used oil should be properly disposed or recycled. Please contact with your local waste liquid/solid

authority for information on recycling.

Summary of Contents for JA1041OD

Page 1: ...1 Pneumatic Oil Extractor Operational Manual Model No JA1041OD ...

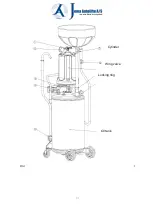

Page 12: ...12 FIG 3 2 Cylinder Locking ring Wing valve Oil tank ...

Page 13: ...13 ...

Page 15: ...15 ...