Jema Autolifte A/S Industrihegnet 2 4030 Tune Denmark Tel. (+45) 48180300

www.jemaautolifte.dk

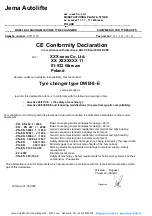

4. DEMOUNTING TYRE

Switch machine and air supply on.

Pull tyre separator lever 21 back, insert wheel between separator arm and rubber cushion on machine

wall and move the arm to touch the tyre, close to wheel rim edge.

BE CAREFUL NOT TO REST THE ARM AGAINST WHEEL RIM

Holding separator arm in appropriate position, depress tyre separator pedal 18 and hold it until the

tyre is separated from wheel edge. If necessary, repeat the operation at several points of wheel

circumference. Then reverse wheel and separate in the same way tyre from wheel rim on the other

side of the wheel.

Fig 6. Separating the tyre

21 - tyre separator lever

By means pedal 17, deflect column backwards. With pedal 16 open table jaws (pedal in mid and

bottom positions). Set - up wheel on work table so that the tyre rests against jaws and shift pedal 16

to top position. Check if jaw hitches gripped wheel rim edge securely. Shift pedal 17 to top position

-the column will revert to the vertical working position). Grip, with your left hand, the top of lever 11

and with your right hand, the slide locking knob 20. Sliding the slide out, to an appropriate distance

and pressing the arm top, make the foot rest on the wheel rim edge, as in fig 9. Then turn knob 20 to

the right arm and slide will be loaded and the foot will automatically adopt the working position,

taking into account the necessary clearance between the foot and the wheel rim. Press tyre edge,

opposite to the foot into wheel rim recess. Rest tyre lever against the support of foot 22 and pull tyre

edge on bulb 23 - as in gigs 10 and 11.

8

Beadbreaker

function

Beadbreaker

function