10000W Dual-Fuel Generator

50

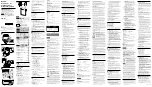

Air Cleaner

APA Part No.

Description

O

G10000EGL

-O-01-JD

G10000EGL

-O-02-JD

G10000EGL

-O-03-JD

G10000EGL

-O-04- D

G10000EGL

-O-05-JD

G10000EGL

-O-07-JD

G10000EGL

-O-06-JD

AIR CLEANER COVER COMP

AIR CLEANER ELEMENT

FLANGE NUT (M5)

AIR CLEANER SEPARATOR

AIR CLEANER SEAL

AIR CLEANER CASE COMP

BREATHER GASKET

JD Part No.

Qty

1

1

6

1

1

1

1

JF240.6.2-1

JF240.6.2-2

JF240.6.2-4

JF240.6.2-3

JF240.6.2-5

JF240.6.1-6

20.6-M5