operation and

maintenance instructions

Model SHC 140, 165, 165B, 165G, 165GT and 205

page 16 of 20

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA E--MAIL.

TEL. 860-347-7271

FAX. 860-347-6978

WWW.

jarvisproducts.com

JARVIS

6207016::::.

3.3 When the desired length of cut is reached, re-

lease the trigger. This will stop the blade from

rotating.

Continue holding the tool with two hands un-

til the saw blade comes to a complete stop.

3.4 Withdraw the saw blade from the carcass.

Note: Avoid banging the blade into bone, as this could

damage the saw due to the cutting power available. All

cuts should be made in a firm, steady motion with the car-

cass supported to prevent it from moving with the pres-

sure of the blade.

MAINTENANCE INSTRUCTIONS

ALWAYS DISCONNECT ALL HYDRAULIC AND AIR

HOSES AND SHUT OFF THE POWER SUPPLY IN AC-

CORDANCE WITH OSHA’S LOCKOUT/TAGOUT PRO-

CEDURES (29 CFR 1910.147) BEFORE PERFORMING

ANY REPAIRS OR MAINTENANCE

.

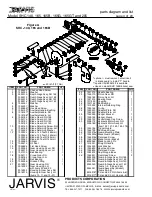

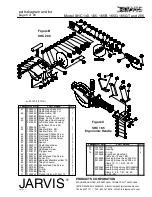

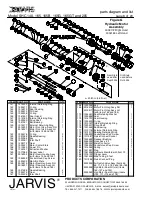

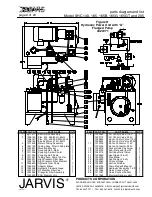

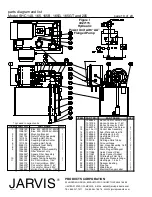

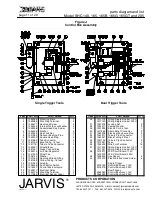

Refer to Figures A to G on pages 4--8 for referenced

items.

1 DAILY:

Note: The hydraulic and air hoses must be

connected and the power turned on to per-

form the above maintenance check only

.

For Single Trigger Tools:

1.1 Make sure that the trigger lever (item 188) is

working correctly. Depress the trigger and the

tool should start. Release the trigger and the tool

should stop.

If the tool malfunctions, repair or

remove it from service immediately

.

For Dual Trigger Tools:

1.2 Make sure that the dual anti--tie down control

triggers on the side and rear handles are working

correctly.

Depress

each trigger separately and

the tool should not start.

Depress

one trigger,

then pause one second and depress the other trig-

ger and the tool should not start. Repeat this pro-

cedure reversing the triggers.

Depress

both trig-

gers simultaneously (within one half second of

each other) and the tool should start. With the

tool running,

release

one trigger and the tool

should stop. Continue holding the depressed

trigger and then depress the other trigger. The

tool should not start.

Repeat

this procedure

holding the other trigger.

If the tool malfunc-

tions, remove it from service and report the

problem to your supervisor immediately

.

Always use two hands when starting and

stopping the tool. Continue holding the tool

with two hands until the saw blade comes to

a complete stop.

1.3 Four (4) times per day, add

Jarvis

1315 White

Grease

to the grease fitting (item 20 or 96) in the

gear housing (item 21, 50 or 99).

1.4 Check the level of the hydraulic fluid in the pow-

er unit.

1.5 Inspect all hoses for leaks, cuts and abrasions

and replace if necessary.

1.6 Check all fittings for leaks and tighten or re-

place, as necessary.

2 WEEKLY:

2.1 Check the condition of the fluid in the hydraulic

power unit. Replace the fluid if it appears dirty

or smells burnt.

Always replace the filters

(items 10 and 15, Figure H, page 9) when chang-

ing the fluid.

3 BLADE REMOVAL:

SHC--140, 165, 165B and 205 Models

3.1 Loosen or remove (SHC--165B) flat head

screws (item 44 or 55) and pivot the blade guard

and gage assembly (item 9, 37 or 48) up and

away from the blade.

3.2 Remove the blade retaining screw (item 10) and

blade retaining washer (item 11) and remove

blade (item 12 or 49).

3.2.1 Place blade locking pin (item 40) through

the hole in the blade to prevent it from rotat-

ing.

3.3 Inspect all parts for wear and replace, as neces-

sary.

3.3.1 Sharpen or replace the blade, as necessary.

SHC--165G Model

3.4 Remove hex head screws (item 79) and separate

cover assembly (items 75--81, 103 and 104)

from blade guard (item 88).

3.5 Remove the blade retaining screw (item 82) us-

ing adjustable spanner wrench (8039093).