20

a

B

forward fEEding Backward fEEding

adjuSting ScrEw

(d)

(c)

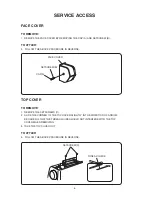

MECHANICAL ADJUSTMENT

BUTTONHOLE FEED BALANCE

TO CHECk:

whEn SEwing ButtonholE, thE StitchES on Each SidE of ButtonholE Should

BE thE SamE Stitch dEnSitY.

thE rangE of 9-12 StitchES in thE right SidE row (Backward fEEding)

againSt 10 StitchES in thE lEft SidE row (forward fEEding) iS conSidErEd

accEptaBlE.

ADJUSTMENT PROCEDURE:

1. chEck thE fEEd BalancE BY SEwing ButtonholES.

2. rEmovE thE cap on thE front covEr.

3. turn thE adjuSting ScrEw in thE dirEction of (c) in caSE of (a) (right StitchES

arE coarSE), or in thE dirEction of (d) in caSE of (B) (lEft StitchES arE coarSE).

4. mount thE cap.

Summary of Contents for NH15

Page 1: ...1 SERVICE MANUAL MODEL NH15 PARTS LIST...

Page 23: ...23 WIRING 1 WIRING FOR MACHINE SOCKET UNIT L M M MOTOR L LAMP M L 120V 240V...

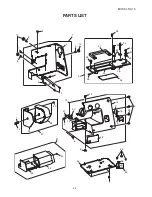

Page 34: ...34 MODEL NH15 PARTS LIST 1 2 3 4 4 5 6 7 8 9 10 11 12 13 14 8 4 15 16 17 8 8 18 19...

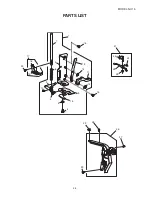

Page 38: ...38 MODEL NH15 PARTS LIST 1 2 3 9 5 8 6 7 4...

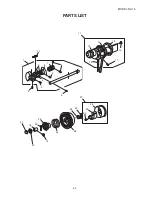

Page 40: ...40 MODEL NH15 PARTS LIST 2 8 1 4 5 7 6 3 9 10 11...