13

7330

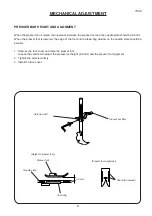

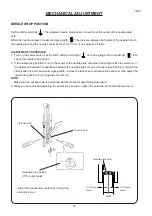

NEEDLE CLEARANCE TO SHUTTLE

The clearance between the needle and the tip of hook should be -0.1 to +0.05 mm.

PREPARATION:

1. Remove the needle plate, bobbin holder, and bed cover, and replace the needle with the test pin (B).

2. Turn the power switch on, and select pattern " " (simploe zigzag). (Maximum zigzag width)

ADJUSTMENT PROCEDURE:

1. Loosen the screws (A), (B), (C), then slightly tighten the hing screw (C).

2. Turn the handwheel toward you, and adjust the clearance between master needle and the point of the hook in

the left and right needle position to –0.1 to +0.05 mm by moving the hook in the left and right by moving the hook

set plate up or down.

3. Tighten the setscrews (A), (B), (C).

4. Check the backlash of the hook drive, gear and lower shaft gear. If the backlash is too great or not enough,

adjust the backlash in accordance with "to adjust the backlash of hook drive gear and lower shaft gear".

5. Attach the bed cover, needle plate and bobbin holder, and remove the master needle.

MECHANICAL ADJUSTMENT

Hinge screw (C)

Setscrew (B)

Hook set plate (E)

Setscrew (A)

Test pin (D)

Point of hook

–0.1 to +0.05 mm