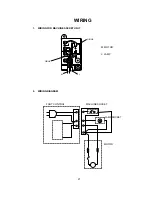

26

300g LOAD

DEFLECTION 7–9MM

(A)

(B)

MECHANICAL ADJUSTMENT

MOTOR BELT TENSION

TO CHECK:

1.

IF THE MOTOR BELT TENSION IS TOO TIGHT OR TOO LOOSE, IT CAN CAUSE A

BELT NOISE: IF THE TENSION IS TOO TIGHT, IT CAN CAUSE THE MACHINE TO RUN

SLOWLY AND THE MOTOR TO OVERLOAD; IF THE TENSION IS TOO LOOSE; IT CAN

CAUSE THE BELT TEETH ON THE MOTOR PULLEY TO JUMP.

2.

THE CORRECT MOTOR BELT TENSION IS WHEN THE DEFLECTION OF MOTOR

BELT IS ABOUT 7MM (0.28") - 9MM (0.36"). (WHEN PUSHING THE MOTOR BELT BY

FINGER WITH A 300 GRAM LOAD.)

ADJUSTMENT PROCEDURE:

1.

REMOVE THE FRONT COVER. (SEE PAGE 9)

2.

LOOSEN THE SCREWS (A) AND (B).

3.

MOVE THE MOTOR UP OR DOWN TO ADJUST THE DEFLECTION ABOUT 7MM (0.28")

- 9MM (0.36").

4.

TIGHTEN THE SCREWS (A) AND (B).