7 / 8

General information

1

2

Janitza electronics GmbH

Vor dem Polstück 6

35633 Lahnau, Germany

Support tel. +49 6441 9642-22

Fax +49 6441 9642-30

E-mail: [email protected]

www.janitza.com

www

.janitza.com

Doc no. 2.100.010.1 05/2018

Item no. 33.03.373

Smart Energy Panel

JPC70

Installation instructions

Installation

Device settings

Deutsche V

ersion:

siehe V

or

derseite

3

2

Safety

Safety instructions

The installation instructions do not include

a complete list of all safety measures necessary

for operating the device.

Special operating conditions may require

additional measures. The installation

instructions contain notes that must be

observed for your personal safety and to

prevent property damage.

ATTENTION

Indicates an imminently dangerous situation

that can result in property damage or

environmental damage in the event of

noncompliance.

NOTE

Points out procedures during which a danger

of injuries or property damage does not exist.

Safety instructions are highlighted by a warning

triangle and are presented as follows depending

on the level of risk:

DANGER

Indicates an imminent danger that will result

in serious and/or fatal injuries.

WARNING

Indicates a potentially dangerous situation

that can result in serious injuries or death.

CAUTION

Indicates a potentially dangerous situation

that can result in minor injuries or property

damage.

Safety measures

When operating electrical devices, specific

parts of these devices inevitably carry

dangerous voltage. As a result, serious bodily

harm or property damage can occur if they are

not handled correctly:

• Before connecting the device, ground it at

the protective conductor terminal if available.

• Dangerous voltages may be present in all

circuit parts connected to the voltage supply.

• There may still be dangerous voltages present

in the device even after it is disconnected

from the supply voltage (capacitor storage).

• Do not exceed the threshold values specified

in the user manual and on the rating

plate. This must also be observed during

inspections and commissioning.

• Observe the safety instructions and warning

notices in the documents that accompany

the devices.

Qualified personnel

To prevent personal injuries and property

damage, only qualified personnel with electrical

engineering training may work on the device.

They must also have knowledge

• Of the national accident prevention

regulations

• In safety technology standards

• In the installation, commissioning and

operation of the device.

Intended use

The device is

• intended for installation in switching cabinets

and small installation distributors. Refer

to the technical data for the installation

location.

• not intended for installation in vehicles! Using

the device in mobile equipment is considered

an unusual environmental condition and is

only permissible by special agreement.

• not intended for installation in areas exposed

to harmful oils, acids, gases, vapors, dust

and radiation, etc.

The prerequisites for smooth and safe operation

of the device include proper transport, storage,

setup and assembly, as well as proper operation

and maintenance.

DANGER

Electrical voltage!

It may result in serious bodily harm or death

due to:

• Touching live exposed or stripped cores.

• Device inputs that are dangerous to touch.

Before starting work, disconnect your

system from the power supply.

Verify that there is no current.

• Cut-out size: 186.8 ±1 mm x 129.8 ±1 mm

• Wall thickness: 2 to 6 mm

Assembly

User manual:

Disclaimer

It is essential that the information products

for the devices are observed to ensure

safe operation and achieve the specified

performance characteristics and product

features. Janitza electronics GmbH assumes

no liability for personal injuries, property

damage and financial losses resulting from the

failure to observe the information products.

Make sure that your information products are

legible and accessible.

You can find more documentation on our web

site www.janitza.de under Support > Downloads.

Copyright notice

© 2018 - Janitza electronics GmbH - Lahnau.

All rights reserved. Any duplication, processing,

distribution and any other kind of use, even in

part, is prohibited.

Subject to technical changes.

• Make sure that the installation instructions

match your device.

• First, make sure you have read and

understood the document accompanying

the product.

• Keep the documents accompanying the

product accessible through its service life

and hand them over to the subsequent

owner where applicable.

• Refer to www.janitza.de for information

concerning device revisions and

the associated adjustments to the

documentation accompanying the product.

Disposal

Please observe the national regulations.

Dispose of individual parts, where necessary,

depending on the properties and existing

country-specific regulations, e.g. as:

• Electronic waste

• Plastic

• Metal

or commission a certified disposal company

with the scrapping.

Relevant laws,

applied standards and directives

Please refer to the Declaration of Conformity

on our web site (www.janitza.de) for the laws,

standards and directives applied by Janitza

electronics GmbH.

CAUTION

Property damage due to noncompliance

with the assembly instructions.

Noncompliance with the assembly instructions

can damage or destroy your device.

Ensure sufficient air circulation in your

installation environment and, where

applicable, sufficient cooling with high

ambient temperatures. Follow the general

ESD protective measures.

NOTE

You can find more detailed information about

the device functions, data and assembly in the

user manual.

Fig. 1: Installation position, side view JPC70

Fig. 2: Installation position, side distances JPC70

Torque: 0.6 Nm.

The device must be installed using the supplied

retaining clamps (see Fig. 06) on a level, clean and

burr-free surface. Unevenness can cause damage

to the display and result in the penetration of dust

and water.

1. Insert the front side of the device in the

provided installation cut-out.

2. Insert the retaining clamps in the recesses

provided on the device.

Fig. 3: Inserting the retaining clamps

3. Slide the retaining clamps towards the rear until

they are flush with the back side of the recess.

Fig. 4: Sliding the retaining clamps towards the rear

4. Fix the retaining clamps by tightening

the fastening screws on the wall and/or

the switch cabinet sheet metal.

Fig. 5: Fixing the retaining clamps

Fig. 6: Rear view with retaining clamps

The stand-by screen with the Janitza logo

appears after the device has been activated

for the first time. Touch the screen to call up the

start-up screen.

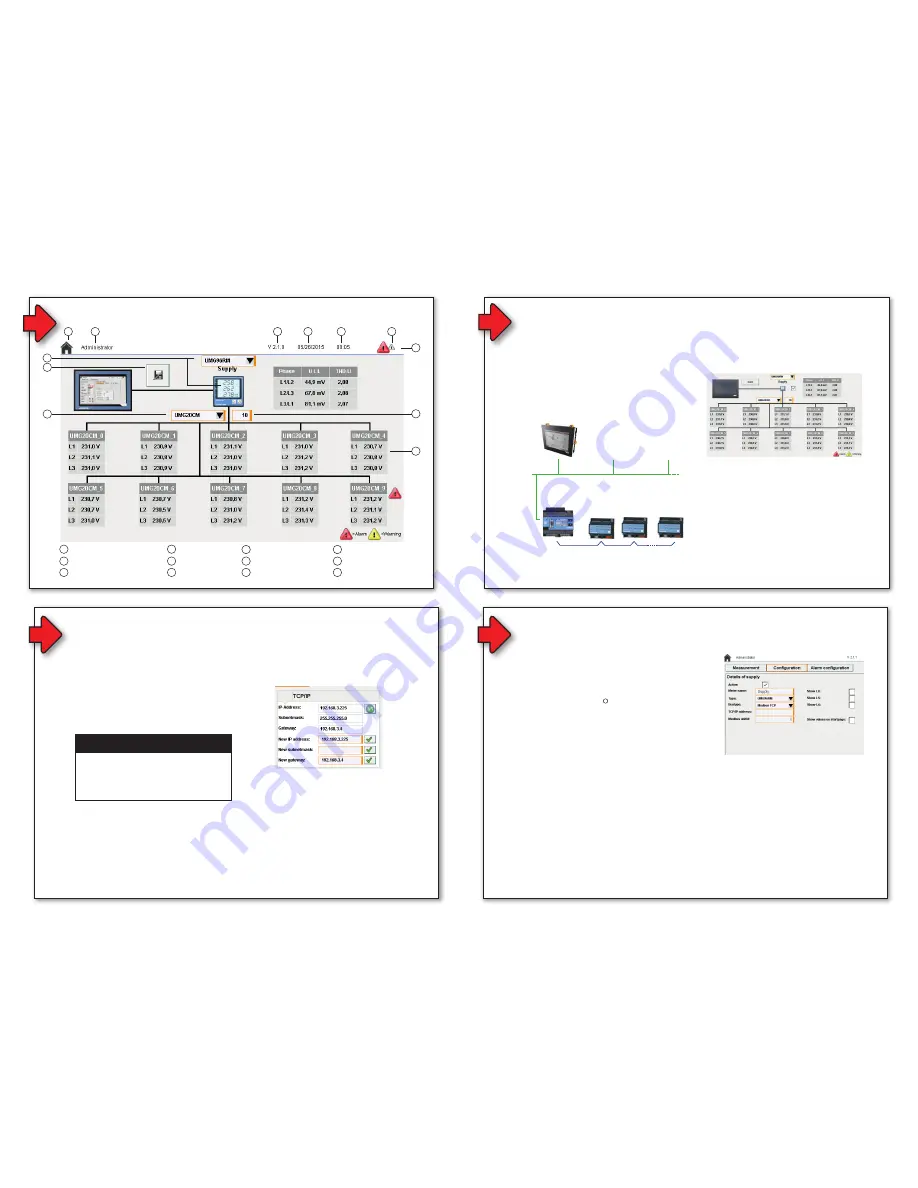

Fig. 11: JPC70 start-up screen

You must be logged in as an administrator to

make configurations on the device.

1. Touch the display of the current role in the

status bar to open the login mask. After a

restart of the system, this is the

ViewOnly

role.

2. Enter login data for the administrator in the

user and password input fields. (the factory

setting for both of these fields is "Admin")

Faults are discharged effectively via a

grounding lug. The cable shield (e.g. Ethernet)

is discharged via the ground plate.

5

Connecting elements and diagnostic LEDs

4

Device connection

Ground conductor:

The connection to the ground potential must

be made as short as possible and adequately

strong (≥4 mm²) via the provided flat plug

connection (Faston 6.3 mm).

2

Unshielded conductors:

All unshielded conductors must be relieved of

tensile stress with cable ties on the ground plate.

1

LED

Color

Description

RDY/F

Yellow BOOT, SERVICE or DIAGNOSIS

mode

R/E

Green

RUN mode: Application running.

Red

BOOT, SERVICE or DIAGNOSIS

mode

Button code

Mode

Description

Press the button briefly (<2 s)

RUN

A hardware reset is initiated:

• All user programs are stopped.

• Outputs of all connected

modules are set to zero.

Then the device starts up in

RUN mode and the application

is started.

Press and hold the button (>2 s)

DIAGNOSIS Only for internal use.

1. Press the button briefly (<2 s)

2. Pause (<2 s)

3. Press and hold the button (>2 s)

BOOT

Only for internal use.

7

CAUTION

Property damage due to noncompli-

ance of the connection conditions or

impermissible voltage swells!

Noncompliance of the connection

conditions or exceeding the permissible

voltage range can damage or destroy

your device.

Before you connect the device to the

supply voltage, please observe the

following:

•

In building installations, secure the

supply voltage with a UL/IEC-listed

circuit breaker/fuse.

•

The circuit breaker

-

must be easily accessible for the

user and located in the vicinity of

the device.

-

must be labeled for the respec-

tive device.

6

1

2

3

4

5

6

7

8

9

1

LED CAN-bus status

6

USB Interface

2

LED: R/E

7

Ethernet interface

3

LED: RDY/F

8

Reset button

4

24V supply voltage

9

CAN-bus interface

(internal)

5

Ground lug

Start screen

1

Selected slave devices

6

Software version

2

Save

button

3

Selected master device

4

Home

button

7

Current date

8

Current time

9

Warnings/alarms

10

Status bar

11

Number of slave devices

12

Slave device (tabular

representation)

5

Active user role

Configuration

2

1

Fig. 7: Rear view - JPC70 with connections

Fig. 8: Rear view - JPC70 connections and LEDs

1

2

3

5

4

6

7

8

9

11

12

10

Fig. 9: JPC70 start-up screen (topology view)

The JPC70 is connected via the Ethernet

interface to a master device in a bus system

in order to be able to manage this bus system

on the JPC70. Refer to the documentation for

the respective master and slave devices for the

configuration of a bus system.

Connect the JPC70 and master device via the

Ethernet interfaces.

JPC70

UMG 605-PRO

as a master

Slave 1

Slave 2

Slave n

Ethernet

Modbus

Modbus

Modbus

Ethernet

Fig. 10: Topology view of a bus system

DANGER

The ground potential (ground lug on the device)

and GND connection of the voltage supply are

connected internally in this device.

Use at least one PELV power supply unit.

The factory settings must be accepted after the

initial commissioning. For this purpose, proceed

as follows:

1. Touch the display of version, date or time

to open the system settings.

2. Press the

ACK

button.

• The standard IP address and gateway are

loaded to the TCP/IP settings.

NOTE

Performing TCP/IP configuration first

is recommended, because assignment

of a fixed IP address without consulting

with the network administrator can result

in complications.

3. Enter an IP address and the corresponding

gateway address under in the

New IP

address

New gateway

text input fields

under

TCP/IP

.

4. Confirm the new address by pressing

the button with the green check mark.

5. Update the view of the IP configuration

by pressing the

Update

button next to the

IP address

text input field.

6. Press the

Save

button to save the settings.

Fig. 12: TCP-IP configuration of the JPC70

Integrating the master device:

8

9

Network settings

Show bus system

1. Log in as an administrator. (See

Step 7

)

2. Navigate back to the start-up screen

by pressing the

Home

button.

3. Open the settings of the master device by

pressing the illustration of a UMG master

device (see Fig. 09

3

).

4. Select the type of the master device

from the

Type

selection list.

5. Select the option Modbus TCP in the

Bus type

selection list.

6. Enter the IP address of the master device

in the

TCP/IP address

text input field.

7. Enter the Modbus address of the master

device in the

Modbus UnitID

text input

field.

8. You can optionally have the values of the

master device displayed on the start-up

screen. For this purpose, activate the

Show values on startpage selection box.

9. Save the settings by pressing the Save

button.

• Proceed with the configuration of the slave

devices.

Fig. 13: Master device configuration

10

General information

Net weight

600 g

Dimensions

197 mm x 140 mm x 47.8 mm

Backlight (LED)

• Brightness: type 500 cd/m

2

• Half brightness time

1)

: 50,000 h

Cooling

Passive

Power button

No

Reset button

Yes

Status display (7 LEDs)

• Supply voltage OK

• Operating status

• Module status

• Ethernet

Processor

ARM Cortex-A8, 1 GHz

Working memory

256 Mbyte DDRAM

Interfaces

USB

2 x USB 2.0 type A rating 0.49 A

Ethernet

• 1x RJ45 shielded

• Max. transmission rate 10/100 Mbit/s

• Cable type: 10BASE-T/100BASE-TX

Ambient conditions

Protection rating according

to EN 60529

IP65 front side, IP20 rear side

Installation elevation above

sea level

0 to 2000 m

Operating temperature

-20 to 60 °C

Storage and transport

temperature

-20 to 70 °C

Air humidity

5 to 96 %, non-condensing

Electrical properties

Supply voltage

24 V DC -15% / +20%

Max. power consumption

2)

6.2 W

Pole reversal protection

Yes

Display

Type

Color TFT

Diagonal

7"

Colors

16.7 million (RGB, 8 bits per channel)

Resolution

WVGA, 800 x 480 pixels

Contrast

typically 600:1

Touchscreen

Yes

Technical data

1) With 25°C ambient temperature. Reduction of brightness

by 50% can increase the half brightness time by about 50%.

2) Without USB interfaces

Integrating slave devices:

1. Switch to the start-up screen.

• The message "Reboot necessary!" appears

after configuration of the master device.

2. Select the appropriate slave device type

from the selection list.

3. Enter the number of slave devices

connected in the bus in the input field next

to the selection list.

4. Now open the configuration for the

respective slave device by touching the

corresponding tabular representation.

5. Enter the Modbus address of the device

in the

Modbus address

input field.

6. Save the settings by pressing the

Save

button.

7. Repeat steps 4-6 for all slave devices

in the bus system.

8. Navigate back to the start-up screen.

9. Save the setting by pressing the

Save

button.

Communication between the master device

and JPC70 takes place via the Modbus TCP

protocol and must be started explicitly:

1. Log in as an administrator.

2. Navigate to the system settings.

3. Activate the selection box if you want

to overwrite the configuration of the

connected devices with the configuration

from the JPC70.

4. Press the start button under

Modbus TCP

.

• The update symbol appears next to the

Modbus TCP

menu item and displays an

active transmission.

Finishing the configuration

The device must be restarted to finish the

configuration:

1. Navigate to the system settings.

2. Press the

Reboot

button under

Device

.

• At this point, you have the opportunity to

save the settings.

NOTE

If the device remains in SERVICE mode

during the restart, disconnect the device

supply voltage and re-connect it after about

2 seconds.

Activating communication via Modbus TCP

Fig. 14: Slave device configuration

Fig. 15: Modbus TCP system settings

General information

1

2

Janitza electronics GmbH

Vor dem Polstück 6

35633 Lahnau, Germany

Support tel. +49 6441 9642-22

Fax +49 6441 9642-30

E-mail: [email protected]

www.janitza.com

www

.janitza.com

Doc no. 2.100.010.1 05/2018

Item no. 33.03.373

Smart Energy Panel

JPC70

Installation instructions

Installation

Device settings

Deutsche V

ersion:

siehe V

or

derseite

3

2

Safety

Safety instructions

The installation instructions do not include

a complete list of all safety measures necessary

for operating the device.

Special operating conditions may require

additional measures. The installation

instructions contain notes that must be

observed for your personal safety and to

prevent property damage.

ATTENTION

Indicates an imminently dangerous situation

that can result in property damage or

environmental damage in the event of

noncompliance.

NOTE

Points out procedures during which a danger

of injuries or property damage does not exist.

Safety instructions are highlighted by a warning

triangle and are presented as follows depending

on the level of risk:

DANGER

Indicates an imminent danger that will result

in serious and/or fatal injuries.

WARNING

Indicates a potentially dangerous situation

that can result in serious injuries or death.

CAUTION

Indicates a potentially dangerous situation

that can result in minor injuries or property

damage.

Safety measures

When operating electrical devices, specific

parts of these devices inevitably carry

dangerous voltage. As a result, serious bodily

harm or property damage can occur if they are

not handled correctly:

• Before connecting the device, ground it at

the protective conductor terminal if available.

• Dangerous voltages may be present in all

circuit parts connected to the voltage supply.

• There may still be dangerous voltages present

in the device even after it is disconnected

from the supply voltage (capacitor storage).

• Do not exceed the threshold values specified

in the user manual and on the rating

plate. This must also be observed during

inspections and commissioning.

• Observe the safety instructions and warning

notices in the documents that accompany

the devices.

Qualified personnel

To prevent personal injuries and property

damage, only qualified personnel with electrical

engineering training may work on the device.

They must also have knowledge

• Of the national accident prevention

regulations

• In safety technology standards

• In the installation, commissioning and

operation of the device.

Intended use

The device is

• intended for installation in switching cabinets

and small installation distributors. Refer

to the technical data for the installation

location.

• not intended for installation in vehicles! Using

the device in mobile equipment is considered

an unusual environmental condition and is

only permissible by special agreement.

• not intended for installation in areas exposed

to harmful oils, acids, gases, vapors, dust

and radiation, etc.

The prerequisites for smooth and safe operation

of the device include proper transport, storage,

setup and assembly, as well as proper operation

and maintenance.

DANGER

Electrical voltage!

It may result in serious bodily harm or death

due to:

• Touching live exposed or stripped cores.

• Device inputs that are dangerous to touch.

Before starting work, disconnect your

system from the power supply.

Verify that there is no current.

• Cut-out size: 186.8 ±1 mm x 129.8 ±1 mm

• Wall thickness: 2 to 6 mm

Assembly

User manual:

Disclaimer

It is essential that the information products

for the devices are observed to ensure

safe operation and achieve the specified

performance characteristics and product

features. Janitza electronics GmbH assumes

no liability for personal injuries, property

damage and financial losses resulting from the

failure to observe the information products.

Make sure that your information products are

legible and accessible.

You can find more documentation on our web

site www.janitza.de under Support > Downloads.

Copyright notice

© 2018 - Janitza electronics GmbH - Lahnau.

All rights reserved. Any duplication, processing,

distribution and any other kind of use, even in

part, is prohibited.

Subject to technical changes.

• Make sure that the installation instructions

match your device.

• First, make sure you have read and

understood the document accompanying

the product.

• Keep the documents accompanying the

product accessible through its service life

and hand them over to the subsequent

owner where applicable.

• Refer to www.janitza.de for information

concerning device revisions and

the associated adjustments to the

documentation accompanying the product.

Disposal

Please observe the national regulations.

Dispose of individual parts, where necessary,

depending on the properties and existing

country-specific regulations, e.g. as:

• Electronic waste

• Plastic

• Metal

or commission a certified disposal company

with the scrapping.

Relevant laws,

applied standards and directives

Please refer to the Declaration of Conformity

on our web site (www.janitza.de) for the laws,

standards and directives applied by Janitza

electronics GmbH.

CAUTION

Property damage due to noncompliance

with the assembly instructions.

Noncompliance with the assembly instructions

can damage or destroy your device.

Ensure sufficient air circulation in your

installation environment and, where

applicable, sufficient cooling with high

ambient temperatures. Follow the general

ESD protective measures.

NOTE

You can find more detailed information about

the device functions, data and assembly in the

user manual.

Fig. 1: Installation position, side view JPC70

Fig. 2: Installation position, side distances JPC70

Torque: 0.6 Nm.

The device must be installed using the supplied

retaining clamps (see Fig. 06) on a level, clean and

burr-free surface. Unevenness can cause damage

to the display and result in the penetration of dust

and water.

1. Insert the front side of the device in the

provided installation cut-out.

2. Insert the retaining clamps in the recesses

provided on the device.

Fig. 3: Inserting the retaining clamps

3. Slide the retaining clamps towards the rear until

they are flush with the back side of the recess.

Fig. 4: Sliding the retaining clamps towards the rear

4. Fix the retaining clamps by tightening

the fastening screws on the wall and/or

the switch cabinet sheet metal.

Fig. 5: Fixing the retaining clamps

Fig. 6: Rear view with retaining clamps

The stand-by screen with the Janitza logo

appears after the device has been activated

for the first time. Touch the screen to call up the

start-up screen.

Fig. 11: JPC70 start-up screen

You must be logged in as an administrator to

make configurations on the device.

1. Touch the display of the current role in the

status bar to open the login mask. After a

restart of the system, this is the

ViewOnly

role.

2. Enter login data for the administrator in the

user and password input fields. (the factory

setting for both of these fields is "Admin")

Faults are discharged effectively via a

grounding lug. The cable shield (e.g. Ethernet)

is discharged via the ground plate.

5

Connecting elements and diagnostic LEDs

4

Device connection

Ground conductor:

The connection to the ground potential must

be made as short as possible and adequately

strong (≥4 mm²) via the provided flat plug

connection (Faston 6.3 mm).

2

Unshielded conductors:

All unshielded conductors must be relieved of

tensile stress with cable ties on the ground plate.

1

LED

Color

Description

RDY/F

Yellow BOOT, SERVICE or DIAGNOSIS

mode

R/E

Green

RUN mode: Application running.

Red

BOOT, SERVICE or DIAGNOSIS

mode

Button code

Mode

Description

Press the button briefly (<2 s)

RUN

A hardware reset is initiated:

• All user programs are stopped.

• Outputs of all connected

modules are set to zero.

Then the device starts up in

RUN mode and the application

is started.

Press and hold the button (>2 s)

DIAGNOSIS Only for internal use.

1. Press the button briefly (<2 s)

2. Pause (<2 s)

3. Press and hold the button (>2 s)

BOOT

Only for internal use.

7

CAUTION

Property damage due to noncompli-

ance of the connection conditions or

impermissible voltage swells!

Noncompliance of the connection

conditions or exceeding the permissible

voltage range can damage or destroy

your device.

Before you connect the device to the

supply voltage, please observe the

following:

•

In building installations, secure the

supply voltage with a UL/IEC-listed

circuit breaker/fuse.

•

The circuit breaker

-

must be easily accessible for the

user and located in the vicinity of

the device.

-

must be labeled for the respec-

tive device.

6

1

2

3

4

5

6

7

8

9

1

LED CAN-bus status

6

USB Interface

2

LED: R/E

7

Ethernet interface

3

LED: RDY/F

8

Reset button

4

24V supply voltage

9

CAN-bus interface

(internal)

5

Ground lug

Start screen

1

Selected slave devices

6

Software version

2

Save

button

3

Selected master device

4

Home

button

7

Current date

8

Current time

9

Warnings/alarms

10

Status bar

11

Number of slave devices

12

Slave device (tabular

representation)

5

Active user role

Configuration

2

1

Fig. 7: Rear view - JPC70 with connections

Fig. 8: Rear view - JPC70 connections and LEDs

1

2

3

5

4

6

7

8

9

11

12

10

Fig. 9: JPC70 start-up screen (topology view)

The JPC70 is connected via the Ethernet

interface to a master device in a bus system

in order to be able to manage this bus system

on the JPC70. Refer to the documentation for

the respective master and slave devices for the

configuration of a bus system.

Connect the JPC70 and master device via the

Ethernet interfaces.

JPC70

UMG 605-PRO

as a master

Slave 1

Slave 2

Slave n

Ethernet

Modbus

Modbus

Modbus

Ethernet

Fig. 10: Topology view of a bus system

DANGER

The ground potential (ground lug on the device)

and GND connection of the voltage supply are

connected internally in this device.

Use at least one PELV power supply unit.

The factory settings must be accepted after the

initial commissioning. For this purpose, proceed

as follows:

1. Touch the display of version, date or time

to open the system settings.

2. Press the

ACK

button.

• The standard IP address and gateway are

loaded to the TCP/IP settings.

NOTE

Performing TCP/IP configuration first

is recommended, because assignment

of a fixed IP address without consulting

with the network administrator can result

in complications.

3. Enter an IP address and the corresponding

gateway address under in the

New IP

address

New gateway

text input fields

under

TCP/IP

.

4. Confirm the new address by pressing

the button with the green check mark.

5. Update the view of the IP configuration

by pressing the

Update

button next to the

IP address

text input field.

6. Press the

Save

button to save the settings.

Fig. 12: TCP-IP configuration of the JPC70

Integrating the master device:

8

9

Network settings

Show bus system

1. Log in as an administrator. (See

Step 7

)

2. Navigate back to the start-up screen

by pressing the

Home

button.

3. Open the settings of the master device by

pressing the illustration of a UMG master

device (see Fig. 09

3

).

4. Select the type of the master device

from the

Type

selection list.

5. Select the option Modbus TCP in the

Bus type

selection list.

6. Enter the IP address of the master device

in the

TCP/IP address

text input field.

7. Enter the Modbus address of the master

device in the

Modbus UnitID

text input

field.

8. You can optionally have the values of the

master device displayed on the start-up

screen. For this purpose, activate the

Show values on startpage selection box.

9. Save the settings by pressing the Save

button.

• Proceed with the configuration of the slave

devices.

Fig. 13: Master device configuration

10

General information

Net weight

600 g

Dimensions

197 mm x 140 mm x 47.8 mm

Backlight (LED)

• Brightness: type 500 cd/m

2

• Half brightness time

1)

: 50,000 h

Cooling

Passive

Power button

No

Reset button

Yes

Status display (7 LEDs)

• Supply voltage OK

• Operating status

• Module status

• Ethernet

Processor

ARM Cortex-A8, 1 GHz

Working memory

256 Mbyte DDRAM

Interfaces

USB

2 x USB 2.0 type A rating 0.49 A

Ethernet

• 1x RJ45 shielded

• Max. transmission rate 10/100 Mbit/s

• Cable type: 10BASE-T/100BASE-TX

Ambient conditions

Protection rating according

to EN 60529

IP65 front side, IP20 rear side

Installation elevation above

sea level

0 to 2000 m

Operating temperature

-20 to 60 °C

Storage and transport

temperature

-20 to 70 °C

Air humidity

5 to 96 %, non-condensing

Electrical properties

Supply voltage

24 V DC -15% / +20%

Max. power consumption

2)

6.2 W

Pole reversal protection

Yes

Display

Type

Color TFT

Diagonal

7"

Colors

16.7 million (RGB, 8 bits per channel)

Resolution

WVGA, 800 x 480 pixels

Contrast

typically 600:1

Touchscreen

Yes

Technical data

1) With 25°C ambient temperature. Reduction of brightness

by 50% can increase the half brightness time by about 50%.

2) Without USB interfaces

Integrating slave devices:

1. Switch to the start-up screen.

• The message "Reboot necessary!" appears

after configuration of the master device.

2. Select the appropriate slave device type

from the selection list.

3. Enter the number of slave devices

connected in the bus in the input field next

to the selection list.

4. Now open the configuration for the

respective slave device by touching the

corresponding tabular representation.

5. Enter the Modbus address of the device

in the

Modbus address

input field.

6. Save the settings by pressing the

Save

button.

7. Repeat steps 4-6 for all slave devices

in the bus system.

8. Navigate back to the start-up screen.

9. Save the setting by pressing the

Save

button.

Communication between the master device

and JPC70 takes place via the Modbus TCP

protocol and must be started explicitly:

1. Log in as an administrator.

2. Navigate to the system settings.

3. Activate the selection box if you want

to overwrite the configuration of the

connected devices with the configuration

from the JPC70.

4. Press the start button under

Modbus TCP

.

• The update symbol appears next to the

Modbus TCP

menu item and displays an

active transmission.

Finishing the configuration

The device must be restarted to finish the

configuration:

1. Navigate to the system settings.

2. Press the

Reboot

button under

Device

.

• At this point, you have the opportunity to

save the settings.

NOTE

If the device remains in SERVICE mode

during the restart, disconnect the device

supply voltage and re-connect it after about

2 seconds.

Activating communication via Modbus TCP

Fig. 14: Slave device configuration

Fig. 15: Modbus TCP system settings

General information

1

2

Janitza electronics GmbH

Vor dem Polstück 6

35633 Lahnau, Germany

Support tel. +49 6441 9642-22

Fax +49 6441 9642-30

E-mail: [email protected]

www.janitza.com

www

.janitza.com

Doc no. 2.100.010.1 05/2018

Item no. 33.03.373

Smart Energy Panel

JPC70

Installation instructions

Installation

Device settings

Deutsche V

ersion:

siehe V

or

derseite

3

2

Safety

Safety instructions

The installation instructions do not include

a complete list of all safety measures necessary

for operating the device.

Special operating conditions may require

additional measures. The installation

instructions contain notes that must be

observed for your personal safety and to

prevent property damage.

ATTENTION

Indicates an imminently dangerous situation

that can result in property damage or

environmental damage in the event of

noncompliance.

NOTE

Points out procedures during which a danger

of injuries or property damage does not exist.

Safety instructions are highlighted by a warning

triangle and are presented as follows depending

on the level of risk:

DANGER

Indicates an imminent danger that will result

in serious and/or fatal injuries.

WARNING

Indicates a potentially dangerous situation

that can result in serious injuries or death.

CAUTION

Indicates a potentially dangerous situation

that can result in minor injuries or property

damage.

Safety measures

When operating electrical devices, specific

parts of these devices inevitably carry

dangerous voltage. As a result, serious bodily

harm or property damage can occur if they are

not handled correctly:

• Before connecting the device, ground it at

the protective conductor terminal if available.

• Dangerous voltages may be present in all

circuit parts connected to the voltage supply.

• There may still be dangerous voltages present

in the device even after it is disconnected

from the supply voltage (capacitor storage).

• Do not exceed the threshold values specified

in the user manual and on the rating

plate. This must also be observed during

inspections and commissioning.

• Observe the safety instructions and warning

notices in the documents that accompany

the devices.

Qualified personnel

To prevent personal injuries and property

damage, only qualified personnel with electrical

engineering training may work on the device.

They must also have knowledge

• Of the national accident prevention

regulations

• In safety technology standards

• In the installation, commissioning and

operation of the device.

Intended use

The device is

• intended for installation in switching cabinets

and small installation distributors. Refer

to the technical data for the installation

location.

• not intended for installation in vehicles! Using

the device in mobile equipment is considered

an unusual environmental condition and is

only permissible by special agreement.

• not intended for installation in areas exposed

to harmful oils, acids, gases, vapors, dust

and radiation, etc.

The prerequisites for smooth and safe operation

of the device include proper transport, storage,

setup and assembly, as well as proper operation

and maintenance.

DANGER

Electrical voltage!

It may result in serious bodily harm or death

due to:

• Touching live exposed or stripped cores.

• Device inputs that are dangerous to touch.

Before starting work, disconnect your

system from the power supply.

Verify that there is no current.

• Cut-out size: 186.8 ±1 mm x 129.8 ±1 mm

• Wall thickness: 2 to 6 mm

Assembly

User manual:

Disclaimer

It is essential that the information products

for the devices are observed to ensure

safe operation and achieve the specified

performance characteristics and product

features. Janitza electronics GmbH assumes

no liability for personal injuries, property

damage and financial losses resulting from the

failure to observe the information products.

Make sure that your information products are

legible and accessible.

You can find more documentation on our web

site www.janitza.de under Support > Downloads.

Copyright notice

© 2018 - Janitza electronics GmbH - Lahnau.

All rights reserved. Any duplication, processing,

distribution and any other kind of use, even in

part, is prohibited.

Subject to technical changes.

• Make sure that the installation instructions

match your device.

• First, make sure you have read and

understood the document accompanying

the product.

• Keep the documents accompanying the

product accessible through its service life

and hand them over to the subsequent

owner where applicable.

• Refer to www.janitza.de for information

concerning device revisions and

the associated adjustments to the

documentation accompanying the product.

Disposal

Please observe the national regulations.

Dispose of individual parts, where necessary,

depending on the properties and existing

country-specific regulations, e.g. as:

• Electronic waste

• Plastic

• Metal

or commission a certified disposal company

with the scrapping.

Relevant laws,

applied standards and directives

Please refer to the Declaration of Conformity

on our web site (www.janitza.de) for the laws,

standards and directives applied by Janitza

electronics GmbH.

CAUTION

Property damage due to noncompliance

with the assembly instructions.

Noncompliance with the assembly instructions

can damage or destroy your device.

Ensure sufficient air circulation in your

installation environment and, where

applicable, sufficient cooling with high

ambient temperatures. Follow the general

ESD protective measures.

NOTE

You can find more detailed information about

the device functions, data and assembly in the

user manual.

Fig. 1: Installation position, side view JPC70

Fig. 2: Installation position, side distances JPC70

Torque: 0.6 Nm.

The device must be installed using the supplied

retaining clamps (see Fig. 06) on a level, clean and

burr-free surface. Unevenness can cause damage

to the display and result in the penetration of dust

and water.

1. Insert the front side of the device in the

provided installation cut-out.

2. Insert the retaining clamps in the recesses

provided on the device.

Fig. 3: Inserting the retaining clamps

3. Slide the retaining clamps towards the rear until

they are flush with the back side of the recess.

Fig. 4: Sliding the retaining clamps towards the rear

4. Fix the retaining clamps by tightening

the fastening screws on the wall and/or

the switch cabinet sheet metal.

Fig. 5: Fixing the retaining clamps

Fig. 6: Rear view with retaining clamps

The stand-by screen with the Janitza logo

appears after the device has been activated

for the first time. Touch the screen to call up the

start-up screen.

Fig. 11: JPC70 start-up screen

You must be logged in as an administrator to

make configurations on the device.

1. Touch the display of the current role in the

status bar to open the login mask. After a

restart of the system, this is the

ViewOnly

role.

2. Enter login data for the administrator in the

user and password input fields. (the factory

setting for both of these fields is "Admin")

Faults are discharged effectively via a

grounding lug. The cable shield (e.g. Ethernet)

is discharged via the ground plate.

5

Connecting elements and diagnostic LEDs

4

Device connection

Ground conductor:

The connection to the ground potential must

be made as short as possible and adequately

strong (≥4 mm²) via the provided flat plug

connection (Faston 6.3 mm).

2

Unshielded conductors:

All unshielded conductors must be relieved of

tensile stress with cable ties on the ground plate.

1

LED

Color

Description

RDY/F

Yellow BOOT, SERVICE or DIAGNOSIS

mode

R/E

Green

RUN mode: Application running.

Red

BOOT, SERVICE or DIAGNOSIS

mode

Button code

Mode

Description

Press the button briefly (<2 s)

RUN

A hardware reset is initiated:

• All user programs are stopped.

• Outputs of all connected

modules are set to zero.

Then the device starts up in

RUN mode and the application

is started.

Press and hold the button (>2 s)

DIAGNOSIS Only for internal use.

1. Press the button briefly (<2 s)

2. Pause (<2 s)

3. Press and hold the button (>2 s)

BOOT

Only for internal use.

7

CAUTION

Property damage due to noncompli-

ance of the connection conditions or

impermissible voltage swells!

Noncompliance of the connection

conditions or exceeding the permissible

voltage range can damage or destroy

your device.

Before you connect the device to the

supply voltage, please observe the

following:

•

In building installations, secure the

supply voltage with a UL/IEC-listed

circuit breaker/fuse.

•

The circuit breaker

-

must be easily accessible for the

user and located in the vicinity of

the device.

-

must be labeled for the respec-

tive device.

6

1

2

3

4

5

6

7

8

9

1

LED CAN-bus status

6

USB Interface

2

LED: R/E

7

Ethernet interface

3

LED: RDY/F

8

Reset button

4

24V supply voltage

9

CAN-bus interface

(internal)

5

Ground lug

Start screen

1

Selected slave devices

6

Software version

2

Save

button

3

Selected master device

4

Home

button

7

Current date

8

Current time

9

Warnings/alarms

10

Status bar

11

Number of slave devices

12

Slave device (tabular

representation)

5

Active user role

Configuration

2

1

Fig. 7: Rear view - JPC70 with connections

Fig. 8: Rear view - JPC70 connections and LEDs

1

2

3

5

4

6

7

8

9

11

12

10

Fig. 9: JPC70 start-up screen (topology view)

The JPC70 is connected via the Ethernet

interface to a master device in a bus system

in order to be able to manage this bus system

on the JPC70. Refer to the documentation for

the respective master and slave devices for the

configuration of a bus system.

Connect the JPC70 and master device via the

Ethernet interfaces.

JPC70

UMG 605-PRO

as a master

Slave 1

Slave 2

Slave n

Ethernet

Modbus

Modbus

Modbus

Ethernet

Fig. 10: Topology view of a bus system

DANGER

The ground potential (ground lug on the device)

and GND connection of the voltage supply are

connected internally in this device.

Use at least one PELV power supply unit.

The factory settings must be accepted after the

initial commissioning. For this purpose, proceed

as follows:

1. Touch the display of version, date or time

to open the system settings.

2. Press the

ACK

button.

• The standard IP address and gateway are

loaded to the TCP/IP settings.

NOTE

Performing TCP/IP configuration first

is recommended, because assignment

of a fixed IP address without consulting

with the network administrator can result

in complications.

3. Enter an IP address and the corresponding

gateway address under in the

New IP

address

New gateway

text input fields

under

TCP/IP

.

4. Confirm the new address by pressing

the button with the green check mark.

5. Update the view of the IP configuration

by pressing the

Update

button next to the

IP address

text input field.

6. Press the

Save

button to save the settings.

Fig. 12: TCP-IP configuration of the JPC70

Integrating the master device:

8

9

Network settings

Show bus system

1. Log in as an administrator. (See

Step 7

)

2. Navigate back to the start-up screen

by pressing the

Home

button.

3. Open the settings of the master device by

pressing the illustration of a UMG master

device (see Fig. 09

3

).

4. Select the type of the master device

from the

Type

selection list.

5. Select the option Modbus TCP in the

Bus type

selection list.

6. Enter the IP address of the master device

in the

TCP/IP address

text input field.

7. Enter the Modbus address of the master

device in the

Modbus UnitID

text input

field.

8. You can optionally have the values of the

master device displayed on the start-up

screen. For this purpose, activate the

Show values on startpage selection box.

9. Save the settings by pressing the Save

button.

• Proceed with the configuration of the slave

devices.

Fig. 13: Master device configuration

10

General information

Net weight

600 g

Dimensions

197 mm x 140 mm x 47.8 mm

Backlight (LED)

• Brightness: type 500 cd/m

2

• Half brightness time

1)

: 50,000 h

Cooling

Passive

Power button

No

Reset button

Yes

Status display (7 LEDs)

• Supply voltage OK

• Operating status

• Module status

• Ethernet

Processor

ARM Cortex-A8, 1 GHz

Working memory

256 Mbyte DDRAM

Interfaces

USB

2 x USB 2.0 type A rating 0.49 A

Ethernet

• 1x RJ45 shielded

• Max. transmission rate 10/100 Mbit/s

• Cable type: 10BASE-T/100BASE-TX

Ambient conditions

Protection rating according

to EN 60529

IP65 front side, IP20 rear side

Installation elevation above

sea level

0 to 2000 m

Operating temperature

-20 to 60 °C

Storage and transport

temperature

-20 to 70 °C

Air humidity

5 to 96 %, non-condensing

Electrical properties

Supply voltage

24 V DC -15% / +20%

Max. power consumption

2)

6.2 W

Pole reversal protection

Yes

Display

Type

Color TFT

Diagonal

7"

Colors

16.7 million (RGB, 8 bits per channel)

Resolution

WVGA, 800 x 480 pixels

Contrast

typically 600:1

Touchscreen

Yes

Technical data

1) With 25°C ambient temperature. Reduction of brightness

by 50% can increase the half brightness time by about 50%.

2) Without USB interfaces

Integrating slave devices:

1. Switch to the start-up screen.

• The message "Reboot necessary!" appears

after configuration of the master device.

2. Select the appropriate slave device type

from the selection list.

3. Enter the number of slave devices

connected in the bus in the input field next

to the selection list.

4. Now open the configuration for the

respective slave device by touching the

corresponding tabular representation.

5. Enter the Modbus address of the device

in the

Modbus address

input field.

6. Save the settings by pressing the

Save

button.

7. Repeat steps 4-6 for all slave devices

in the bus system.

8. Navigate back to the start-up screen.

9. Save the setting by pressing the

Save

button.

Communication between the master device

and JPC70 takes place via the Modbus TCP

protocol and must be started explicitly:

1. Log in as an administrator.

2. Navigate to the system settings.

3. Activate the selection box if you want

to overwrite the configuration of the

connected devices with the configuration

from the JPC70.

4. Press the start button under

Modbus TCP

.

• The update symbol appears next to the

Modbus TCP

menu item and displays an

active transmission.

Finishing the configuration

The device must be restarted to finish the

configuration:

1. Navigate to the system settings.

2. Press the

Reboot

button under

Device

.

• At this point, you have the opportunity to

save the settings.

NOTE

If the device remains in SERVICE mode

during the restart, disconnect the device

supply voltage and re-connect it after about

2 seconds.

Activating communication via Modbus TCP

Fig. 14: Slave device configuration

Fig. 15: Modbus TCP system settings

General information

1

2

Janitza electronics GmbH

Vor dem Polstück 6

35633 Lahnau, Germany

Support tel. +49 6441 9642-22

Fax +49 6441 9642-30

E-mail: [email protected]

www.janitza.com

www

.janitza.com

Doc no. 2.100.010.1 05/2018

Item no. 33.03.373

Smart Energy Panel

JPC70

Installation instructions

Installation

Device settings

Deutsche V

ersion:

siehe V

or

derseite

3

2

Safety

Safety instructions

The installation instructions do not include

a complete list of all safety measures necessary

for operating the device.

Special operating conditions may require

additional measures. The installation

instructions contain notes that must be

observed for your personal safety and to

prevent property damage.

ATTENTION

Indicates an imminently dangerous situation

that can result in property damage or

environmental damage in the event of

noncompliance.

NOTE

Points out procedures during which a danger

of injuries or property damage does not exist.

Safety instructions are highlighted by a warning

triangle and are presented as follows depending

on the level of risk:

DANGER

Indicates an imminent danger that will result

in serious and/or fatal injuries.

WARNING

Indicates a potentially dangerous situation

that can result in serious injuries or death.

CAUTION

Indicates a potentially dangerous situation

that can result in minor injuries or property

damage.

Safety measures

When operating electrical devices, specific

parts of these devices inevitably carry

dangerous voltage. As a result, serious bodily

harm or property damage can occur if they are

not handled correctly:

• Before connecting the device, ground it at

the protective conductor terminal if available.

• Dangerous voltages may be present in all

circuit parts connected to the voltage supply.

• There may still be dangerous voltages present

in the device even after it is disconnected

from the supply voltage (capacitor storage).

• Do not exceed the threshold values specified

in the user manual and on the rating

plate. This must also be observed during

inspections and commissioning.

• Observe the safety instructions and warning

notices in the documents that accompany

the devices.

Qualified personnel

To prevent personal injuries and property

damage, only qualified personnel with electrical

engineering training may work on the device.

They must also have knowledge

• Of the national accident prevention

regulations

• In safety technology standards

• In the installation, commissioning and

operation of the device.

Intended use

The device is

• intended for installation in switching cabinets

and small installation distributors. Refer

to the technical data for the installation

location.

• not intended for installation in vehicles! Using

the device in mobile equipment is considered

an unusual environmental condition and is

only permissible by special agreement.

• not intended for installation in areas exposed

to harmful oils, acids, gases, vapors, dust

and radiation, etc.

The prerequisites for smooth and safe operation

of the device include proper transport, storage,

setup and assembly, as well as proper operation

and maintenance.

DANGER

Electrical voltage!

It may result in serious bodily harm or death

due to:

• Touching live exposed or stripped cores.

• Device inputs that are dangerous to touch.

Before starting work, disconnect your

system from the power supply.

Verify that there is no current.

• Cut-out size: 186.8 ±1 mm x 129.8 ±1 mm

• Wall thickness: 2 to 6 mm

Assembly

User manual:

Disclaimer

It is essential that the information products

for the devices are observed to ensure

safe operation and achieve the specified

performance characteristics and product

features. Janitza electronics GmbH assumes

no liability for personal injuries, property

damage and financial losses resulting from the

failure to observe the information products.

Make sure that your information products are

legible and accessible.

You can find more documentation on our web

site www.janitza.de under Support > Downloads.

Copyright notice

© 2018 - Janitza electronics GmbH - Lahnau.

All rights reserved. Any duplication, processing,

distribution and any other kind of use, even in

part, is prohibited.

Subject to technical changes.

• Make sure that the installation instructions

match your device.

• First, make sure you have read and

understood the document accompanying

the product.

• Keep the documents accompanying the

product accessible through its service life

and hand them over to the subsequent

owner where applicable.

• Refer to www.janitza.de for information

concerning device revisions and

the associated adjustments to the

documentation accompanying the product.

Disposal

Please observe the national regulations.

Dispose of individual parts, where necessary,

depending on the properties and existing

country-specific regulations, e.g. as:

• Electronic waste

• Plastic

• Metal

or commission a certified disposal company

with the scrapping.

Relevant laws,

applied standards and directives

Please refer to the Declaration of Conformity

on our web site (www.janitza.de) for the laws,

standards and directives applied by Janitza

electronics GmbH.

CAUTION

Property damage due to noncompliance

with the assembly instructions.

Noncompliance with the assembly instructions

can damage or destroy your device.

Ensure sufficient air circulation in your

installation environment and, where

applicable, sufficient cooling with high

ambient temperatures. Follow the general

ESD protective measures.

NOTE

You can find more detailed information about

the device functions, data and assembly in the

user manual.

Fig. 1: Installation position, side view JPC70

Fig. 2: Installation position, side distances JPC70

Torque: 0.6 Nm.

The device must be installed using the supplied

retaining clamps (see Fig. 06) on a level, clean and

burr-free surface. Unevenness can cause damage

to the display and result in the penetration of dust

and water.

1. Insert the front side of the device in the

provided installation cut-out.

2. Insert the retaining clamps in the recesses

provided on the device.

Fig. 3: Inserting the retaining clamps

3. Slide the retaining clamps towards the rear until

they are flush with the back side of the recess.

Fig. 4: Sliding the retaining clamps towards the rear

4. Fix the retaining clamps by tightening

the fastening screws on the wall and/or

the switch cabinet sheet metal.

Fig. 5: Fixing the retaining clamps

Fig. 6: Rear view with retaining clamps

The stand-by screen with the Janitza logo

appears after the device has been activated

for the first time. Touch the screen to call up the

start-up screen.

Fig. 11: JPC70 start-up screen

You must be logged in as an administrator to

make configurations on the device.

1. Touch the display of the current role in the

status bar to open the login mask. After a

restart of the system, this is the

ViewOnly

role.

2. Enter login data for the administrator in the

user and password input fields. (the factory

setting for both of these fields is "Admin")

Faults are discharged effectively via a

grounding lug. The cable shield (e.g. Ethernet)

is discharged via the ground plate.

5

Connecting elements and diagnostic LEDs

4

Device connection

Ground conductor:

The connection to the ground potential must

be made as short as possible and adequately

strong (≥4 mm²) via the provided flat plug

connection (Faston 6.3 mm).

2

Unshielded conductors:

All unshielded conductors must be relieved of

tensile stress with cable ties on the ground plate.

1

LED

Color

Description

RDY/F

Yellow BOOT, SERVICE or DIAGNOSIS

mode

R/E

Green

RUN mode: Application running.

Red

BOOT, SERVICE or DIAGNOSIS

mode

Button code

Mode

Description

Press the button briefly (<2 s)

RUN

A hardware reset is initiated:

• All user programs are stopped.

• Outputs of all connected

modules are set to zero.

Then the device starts up in

RUN mode and the application

is started.

Press and hold the button (>2 s)

DIAGNOSIS Only for internal use.

1. Press the button briefly (<2 s)

2. Pause (<2 s)

3. Press and hold the button (>2 s)

BOOT

Only for internal use.

7

CAUTION

Property damage due to noncompli-

ance of the connection conditions or

impermissible voltage swells!

Noncompliance of the connection

conditions or exceeding the permissible

voltage range can damage or destroy

your device.

Before you connect the device to the

supply voltage, please observe the

following:

•

In building installations, secure the

supply voltage with a UL/IEC-listed

circuit breaker/fuse.

•

The circuit breaker

-

must be easily accessible for the

user and located in the vicinity of

the device.

-

must be labeled for the respec-

tive device.

6

1

2

3

4

5

6

7

8

9

1

LED CAN-bus status

6

USB Interface

2

LED: R/E

7

Ethernet interface

3

LED: RDY/F

8

Reset button

4

24V supply voltage

9

CAN-bus interface

(internal)

5

Ground lug

Start screen

1

Selected slave devices

6

Software version

2

Save

button

3

Selected master device

4

Home

button

7

Current date

8

Current time

9

Warnings/alarms

10

Status bar

11

Number of slave devices

12

Slave device (tabular

representation)

5

Active user role

Configuration

2

1

Fig. 7: Rear view - JPC70 with connections

Fig. 8: Rear view - JPC70 connections and LEDs

1

2

3

5

4

6

7

8

9

11

12

10

Fig. 9: JPC70 start-up screen (topology view)

The JPC70 is connected via the Ethernet

interface to a master device in a bus system

in order to be able to manage this bus system

on the JPC70. Refer to the documentation for

the respective master and slave devices for the

configuration of a bus system.

Connect the JPC70 and master device via the

Ethernet interfaces.

JPC70

UMG 605-PRO

as a master

Slave 1

Slave 2

Slave n

Ethernet

Modbus

Modbus

Modbus

Ethernet

Fig. 10: Topology view of a bus system

DANGER

The ground potential (ground lug on the device)

and GND connection of the voltage supply are

connected internally in this device.

Use at least one PELV power supply unit.

The factory settings must be accepted after the

initial commissioning. For this purpose, proceed

as follows:

1. Touch the display of version, date or time

to open the system settings.

2. Press the

ACK

button.

• The standard IP address and gateway are

loaded to the TCP/IP settings.

NOTE

Performing TCP/IP configuration first

is recommended, because assignment

of a fixed IP address without consulting

with the network administrator can result

in complications.

3. Enter an IP address and the corresponding

gateway address under in the

New IP

address

New gateway

text input fields

under

TCP/IP

.

4. Confirm the new address by pressing

the button with the green check mark.

5. Update the view of the IP configuration

by pressing the

Update

button next to the

IP address

text input field.

6. Press the

Save

button to save the settings.

Fig. 12: TCP-IP configuration of the JPC70

Integrating the master device:

8

9

Network settings

Show bus system

1. Log in as an administrator. (See

Step 7

)

2. Navigate back to the start-up screen

by pressing the

Home

button.

3. Open the settings of the master device by

pressing the illustration of a UMG master

device (see Fig. 09

3

).

4. Select the type of the master device

from the

Type

selection list.

5. Select the option Modbus TCP in the

Bus type

selection list.

6. Enter the IP address of the master device

in the

TCP/IP address

text input field.

7. Enter the Modbus address of the master

device in the

Modbus UnitID

text input

field.

8. You can optionally have the values of the

master device displayed on the start-up

screen. For this purpose, activate the

Show values on startpage selection box.

9. Save the settings by pressing the Save

button.

• Proceed with the configuration of the slave

devices.

Fig. 13: Master device configuration

10

General information

Net weight

600 g

Dimensions

197 mm x 140 mm x 47.8 mm

Backlight (LED)

• Brightness: type 500 cd/m

2

• Half brightness time

1)

: 50,000 h

Cooling

Passive

Power button

No

Reset button

Yes

Status display (7 LEDs)

• Supply voltage OK

• Operating status

• Module status

• Ethernet

Processor

ARM Cortex-A8, 1 GHz

Working memory

256 Mbyte DDRAM

Interfaces

USB

2 x USB 2.0 type A rating 0.49 A

Ethernet

• 1x RJ45 shielded

• Max. transmission rate 10/100 Mbit/s

• Cable type: 10BASE-T/100BASE-TX

Ambient conditions

Protection rating according

to EN 60529

IP65 front side, IP20 rear side

Installation elevation above

sea level

0 to 2000 m

Operating temperature

-20 to 60 °C

Storage and transport

temperature

-20 to 70 °C

Air humidity

5 to 96 %, non-condensing

Electrical properties

Supply voltage

24 V DC -15% / +20%

Max. power consumption

2)

6.2 W

Pole reversal protection

Yes

Display

Type

Color TFT

Diagonal

7"

Colors

16.7 million (RGB, 8 bits per channel)

Resolution

WVGA, 800 x 480 pixels

Contrast

typically 600:1

Touchscreen

Yes

Technical data

1) With 25°C ambient temperature. Reduction of brightness

by 50% can increase the half brightness time by about 50%.

2) Without USB interfaces

Integrating slave devices:

1. Switch to the start-up screen.

• The message "Reboot necessary!" appears

after configuration of the master device.

2. Select the appropriate slave device type

from the selection list.

3. Enter the number of slave devices

connected in the bus in the input field next

to the selection list.

4. Now open the configuration for the

respective slave device by touching the

corresponding tabular representation.

5. Enter the Modbus address of the device

in the

Modbus address

input field.

6. Save the settings by pressing the

Save

button.

7. Repeat steps 4-6 for all slave devices

in the bus system.

8. Navigate back to the start-up screen.

9. Save the setting by pressing the

Save

button.

Communication between the master device

and JPC70 takes place via the Modbus TCP

protocol and must be started explicitly:

1. Log in as an administrator.

2. Navigate to the system settings.

3. Activate the selection box if you want

to overwrite the configuration of the

connected devices with the configuration

from the JPC70.

4. Press the start button under

Modbus TCP

.

• The update symbol appears next to the

Modbus TCP

menu item and displays an

active transmission.

Finishing the configuration

The device must be restarted to finish the

configuration:

1. Navigate to the system settings.

2. Press the

Reboot

button under

Device

.

• At this point, you have the opportunity to

save the settings.

NOTE

If the device remains in SERVICE mode

during the restart, disconnect the device

supply voltage and re-connect it after about

2 seconds.

Activating communication via Modbus TCP

Fig. 14: Slave device configuration

Fig. 15: Modbus TCP system settings