MODEL 220

HYDRAULIC

IMPACT HAMMER

IV.

MAINTENANCE AND ADJUSTMENTS

S. CHECKING & REPLACING RECOIL DAMPENER

The thickness of a new recoil dampener with hammer weight on dampener is 1

1/2"(38mm). If the thickness is less than 1 1/4"(32mm), the dampener should be

replaced.

To replace recoil dampener: Loosen wire rope holding drive cap to hammer. Pick

up hammer to allow old dampener to be removed. Replace with new dampener.

Re-tighten clamps on wire rope. Wire rope should be adjusted so that with hammer

lifted 1-2"(25-50mm) gap exists between recoil dampener and hammer base plate

(160451).

See FIG 3, Page II-7, for location of recoil dampener

T. CHECKING & REPLACING CUSHION MATERIAL

With new cushion material, the striker plate flange should be 2" (45mm) above the

top of a DCB-1 Drive Cap (32" leads). If this dimension is reduced by more than

1/2"(13mm), replace the cushion material.

See Section II F Page II-6 ATTACHMENT OF DRIVECAP for instructions on

replacing cushion material.

IV-15

Summary of Contents for 220

Page 2: ...MODEL 220 HYDRAULIC IMPACT HAMMER ...

Page 4: ...MODEL 220 HYDRAULIC IMPACT HAMMER ...

Page 24: ...MODEL 220 HYDRAULIC IMPACT HAMMER ...

Page 48: ...MODEL 220 HYDRAULIC IMPACT HAMMER ...

Page 52: ...MODEL 220 HYDRAULIC IMPACT HAMMER ...

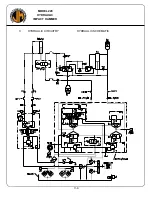

Page 54: ...MODEL 220 HYDRAULIC IMPACT HAMMER V HYDRAULIC CIRCUITRY HYDRAULIC SCHEMATIC V 4 ...

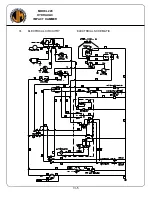

Page 59: ...MODEL 220 HYDRAULIC IMPACT HAMMER VI ELECTRICAL CIRCUITRY ELECTRICAL LAYOUT VI 4 ...

Page 60: ...MODEL 220 HYDRAULIC IMPACT HAMMER VI ELECTRICAL CIRCUITRY ELECTRICAL SCHEMATIC VI 5 ...

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 75: ......

Page 76: ......

Page 78: ......

Page 80: ......