MAINTENANCE 8

27

8.11 LUBRICATION ____________________________________________________________

The mower was designed for minimum lubrication. Over

greasing will produce high loads on the bearings and

engine; thereby reducing the performance of the

machine.

All maintenance intervals must be performed more

frequently when operating in extremely dusty conditions.

1. Always clean the grease fitting before and after

lubricating.

2. Apply grease with a manual grease gun and fill

slowly until grease begins to seep out. DO NOT use

compressed air guns.

3. For smooth operation of pivot points and other

friction points, apply several drops of SAE 30W oil.

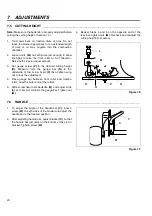

Figure 8D

8.12 MAINTENANCE CHART _____________________________________________________

Recommended Inspection and Lubrication Intervals.

Daily

20

50

100

300

Yearly

Lubricant

Air Cleaner.......................................I ........................................C

Combustion Chamber........................................................................................................... C

Engine Oil ........................................I .................. R ........................................R..........................................

...................... I

Fuel Line ............................................................................................................................................... R - 2 yrs

Spark Plug .....................................................................................................A/R

Valve Clearance ................................................................................................................... A

Grease Locations (Figure 7C)

1 - Roller .......................................................... L.................................................................................... L

.................... II

2 - Height Adj. ........................................................................ L

............................................................................................ II

3 - RT Reel Shaft ............................................. L......................................................................................

..................... II

4 - Traction Roller............................................. L......................................................................................

..................... II

5 - Clutch Shaft Bearing .......................................................................................................................... L

.................... II

6 - Clutch Pivot Shaft .............................................................................................................................. L

....................III

7 - Clutch Needle Bearing ........................................................................................................................

................... III

★

8 - Traction Hub ........................... ................... L......................................................................................

.....................III

9 - Wheel Bearings ............................................................................................................ .................... L

.................... II

10 - Reel Clutch Lever ..................................... L......................................................................................

..................... II

11 - Chain Case ................................................................................................................. ....................R

....................IV

A - Add or Adjust C - Clean I - Inspect L- Lubricate R - Replace

Lubricants

I

- SAE 10W-30 Classified API SF or SG.

II

- Lithium Grease NLGI - Grade 2.

III

- Lubriplate® grease, Jacobsen Part No. 5001581

IV

- SAE EP-140 Oil - Drain and Refill

★

- Apply a light coat

1

2

1

2

3

4

5

6

7

8

9

10

11

Summary of Contents for PGM 22

Page 28: ...9 NOTES 28 9 NOTES ...

Page 29: ...NOTES 9 29 ...

Page 56: ...9 NOTER 28 9 NOTER ...

Page 76: ......

Page 77: ......