21

07610-003-61-42-T

COMMON PROBLEMS

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

REMEDY

Machine doesn’t

drain when power

button is pressed.

1. Drain clogged.

2. Standpipe not removed prior to

drain.

3. Defective drain valve.

1. Remove obstruction.

2. Remove standpipe and run drain cycle again.

3. Replace.

No indication of

pressure.

1. Water turned off.

2. Transducer disconnected.

3. Pressure transducer defective.

1. Turn water on.

2. Verify wiring.

3. Replace pressure transducer.

Wash water is not

reaching required

temperature.

1. Faulty wash heater.

2. Misadjusted/faulty thermostat(s).

3. Wash thermometer is defective.

1. Check element for continuity; if open, replace the heater.

2. Verify operation and setting of thermostats, replace if

necessary.

3. Replace thermometer.

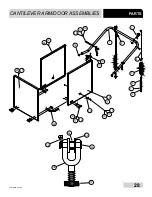

Doors will not close

completely.

1. Improper spring tension.

2. Obstruction in door channel.

3.Doors are not square with frame.

1. Adjust spring tension as required by loosening (not

removing) spring bolt nuts and adjusting the tension.

Tighten nuts back when done.

2. Remove the obstruction.

3. Adjust the frame to accommodate the doors.

Water leaks at the

wash pump.

1. Wash pump seal defective.

2. Petcock or pump drain (if

equipped) not shut/tight.

3. Loose hoses (hose clamps) on

the wash pump.

1. Replace the seal.

2. Close or tighten.

Tighten the hose clamps.

Will not rinse during

autocycle.

1. Defective rinse solenoid.

2. Faulty timer.

3.No water to the machine.

1. Repair or replace the rinse solenoid as required.

2. Replace timer.

3. Verify that there is water at 10 PSI connected to the

machine.

Dishes are not

coming clean.

1. Machine temperatures are not up

to the minimum requirements.

2. No detergent/too much

detergent.

3. Solid dispenser canister is empty.

1. Verify that incoming water, rinse water, and wash

water match the required temperatures as listed on the

machine data plate.

2. Adjust detergent concentration as required for the

amount of water held by the machine.

3. Replace the canister.

WARNING:

Inspection, testing and repair of electrical equipment should only be performed by a qualifi ed service

technician. Many of the tests require that the unit have power to it and live electrical components be exposed.

USE EXTREME CAUTION WHEN TESTING THE MACHINE.

Summary of Contents for TEMPSTAR

Page 2: ......

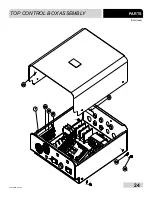

Page 31: ...24 07610 003 61 42 T TOP CONTROL BOX ASSEMBLY PARTS Continued 26 1 29 28 30 33 34 36 ...

Page 66: ...59 07610 003 61 42 T PARTS TEMPSTAR VENTLESS SYSTEM ASSEMBLY ...

Page 77: ...70 TEMPSTAR 460 V 60 HZ 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Page 79: ...72 TEMPSTAR LT NB 208 230V 50 60HZ 1 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Page 82: ...75 07610 003 61 42 T SCHEMATICS SDI OPTIONS ...

Page 83: ...76 07610 003 61 42 T DRAIN QUENCH OPTIONS SCHEMATICS ...

Page 85: ......