07610-004-33-05-E

21

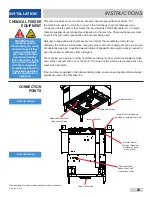

All electrical connections must be made in accordance with applicable portions of local,

state, territorial, and national codes.

Refer to the data plate for machine operating requirements, machine voltage, total

amperage and serial number.

1. Locate main power terminal blocks (for the machine and for the rinse booster

heater, for dual-point, one block for single-point) at the top of the machine.

2. Remove top cover to access terminal blocks.

3. Route incoming power lines within conduit that will connect via fittings to the pre-

punched holes in the back of the control box.

4.

Install power and ground wires to lugs as indicated by the appropriate decals in the

control box. Use copper conductors only. Use of an anti-oxidation agent is

permissible on the power connections.

5. Tighten all connections.

6. Verify incoming voltage matches the voltage indicated on the decal next to the

incoming power pre-punched hole.

For dual-point connection, machine has a separate power connection from

the rinse booster heater and the circuit protection requirements are different

for each. Refer to the machine data plate for information on minimum circuit

protection.

CAUTION!

Improperly connecting external devices can cause damage to the machine

and/or electrical infrastructure! See the External Device Wiring section.

STEAM LINE

CONNECTION

ELECTRICAL

POWER

CONNECTIONS

Disconnect electrical

power at the breaker

or disconnect switch

and tag-out in

accordance with

procedures and codes.

!

CAUTION

i

INSTALLATION

INSTRUCTIONS

L1

L2

L3

Ground

3

Φ

Ground

L1

L2

L3

3

Φ

3

Φ

i

Imbalanced

wild leg goes

to L3.

NOTICE

NOTICE

The steam machines come with lines to connect the source steam. Connect all steam

lines to the machine as all applicable codes provide. See machine data plate for

information concerning steam flow pressure.