07610-004-29-29-D

16

OPERATION

OPERATING INSTRUCTIONS

DETERGENT

CONTROL

Detergent usage and water hardness are two factors that contribute greatly to how

efficiently this machine will operate. Using detergent in the proper amount can

become a source of substantial savings. A qualified water-treatment specialist can

determine what is needed for maximum efficiency from the detergent.

1. Hard water greatly affects the performance of the machine, causing the amount

of detergent required for washing to increase. If the machine is installed in

an area with hard water, the manufacturer recommends the installation of the

Scaltrol Water Treatment system.

2. Deposited solids from hard water can cause spotting that will not be removed

with a drying agent. Treated water will reduce this occurence.

3. Treated water might not be suitable for use in other areas of operation and it

might be necessary to install a water treatment system for the water going to the

machine only. Discuss this option with a qualified water treatment specialist.

4. Operators should be properly trained on how much detergent is to be used per

cycle. Meet with a water treatment specialist and chemical supplier to discuss a

complete training program for operators.

5. Chemicals must be provided for proper operation and sanitization and require the

installation of third-party chemical feeders to introduce these chemicals to the

machine. Contact a chemical supplier with any questions.

6. Water temperature is an important factor in ensuring the machine functions

properly, and the machine's data plate details what the minimum temperatures

must be for the incoming water supply, the wash tank, and the rinse tank. If

minimum requirements are not met, it's possible that dishes will not be clean or

sanitized.

7. Instruct operators to observe the required temperatures and to report when they

fall below the minimum allowed. A loss of temperature can indicate a larger

problem.

i

Summary of Contents for Dynatemp Series

Page 2: ......

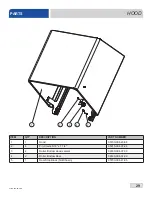

Page 39: ...07610 004 29 29 D 32 11 10 9 12 13 19 20 4 18 17 16 14 15 1 2 3 5 6 7 8 21 TUB PARTS ...

Page 41: ...07610 004 29 29 D 34 11 10 13 18 19 4 17 16 15 1 2 3 5 7 8 6 12 14 9 STEAM TUB PARTS ...

Page 45: ...07610 004 29 29 D 38 PARTS WASH RINSE ARMS 1 2 3 4 5 6 7 8 9 10 11 ...

Page 67: ......