6

Par-MaX serViCe instrUCtions

The PAR-MAX rinse water supply pump needs no

periodic maintenance for proper performance. The only

time service work should need to be performed on the

pump is if it should begin to leak water, suddenly

delivers less water than normal or should stop pumping

altogether. Should the pump begin to leak water, it will

be necessary to replace the diaphragm. If the pump

delivers a reduced rate of flow from normal or stops

pumping altogether, it will be necessary to either

remove debris from the pump’s flapper valves or replace

the valve cage assembly.

NOTIcE:

Before performing any service, turn off the

electrical power to the toilet and rinse water pump. Take

precaution to ensure it is not turned on until service is

complete. Close the inlet fitting seacock.

It is generally easiest to remove the pump from its

installed position so that the service can be performed

on a work bench. To do this, disconnect the electrical

wires from the motor wire leads. Push the port retainer

clips back toward the pump motor and pull the port

fittings from the port sockets. Unscrew the four pump

mounting fasteners and remove the pump to a location

where it can be disassembled without losing any of the

pump components.

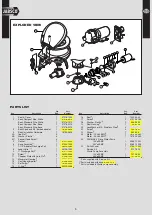

Loosen the four 5/16

"

hex (slotted) machine screws in

the pump body and remove the body from the motor

and wobble plate housing (use care to not drop and

lose the port retainer clips and body retaining screws

and washers). The valve cage will now be exposed

which can be easily lifted off the diaphragm. Inspect the

four outer inlet valves and central discharge valve to

ensure they seat smoothly against the valve cage.

Lift the outer edges of each valve to make certain there

is no debris lodged under any valve. If there is debris

lodged under any of the valves, it will cause a diminished

flow rate or loss of flow entirely. If the valves do not seat

smoothly against the valve cage, the valve cage

assembly should be replaced. If the pump has been

leaking, the diaphragm must be replaced. Remove the

four phillips head diaphragm retainer screws and

mushroom shaped diaphragm retainer caps. Remove

the diaphragm and diaphragm housing from the motor

and wobble plate housing. Inspect the wobble plate

bearing to make certain it is not corroded and still

rotates smoothly.

With the new diaphragm positioned in the diaphragm

housing (ensure the raised sealing beads face outward

away from the motor) hold it against the wobble plate

with the four retaining cap holes aligned with the wobble

plate sockets. Push each diaphragm retainer cap

through the diaphragm and into the socket of the wobble

plate. Secure each retaining cap to the wobble plate

with a 1

"

phillips head retainer screw. Place the motor

on its rear end bell and position the valve cage against

the diaphragm ensuring each cavities seal groove is

seated on its sealing bead molded into the diaphragm.

Ensure the O-ring seal that separates the pumps intake

chamber from the discharge chamber is properly seated

in the ID of the raised lip around the central discharge

valve. While holding the port retainer clips in their slide

grooves in the pump body, position the body on the

diaphragm and inside the wobble plate housing. Secure

the pump body to the wobble plate housing with the four

2-1/4

"

machine screws and flat washers.

Reinstall the pump to its mounting surface with four

fasteners through the rubber grommets. Ensure the

sealing O-ring is properly positioned on each port fitting

and, with the retaining clips slid back, push each port

fitting into its respective socket.

Slide each port retainer clip forward until it snaps

securely into its seated position. Reconnect the orange

motor lead to the positive supply wire and the black

motor lead to the negative wire.

Ensure the inlet seacock is open before restoring power

to and operating the toilet.

one year liMiteD Warranty

A. LIMITED WARRANTY:

JABSCO warrants that at

the time of shipment, the products manufactured by

JABSCO and sold hereunder shall be in conformity with

applicable written specifications and descriptions

referred to or set forth herein, free from defects in

material and workmanship, merchantable, and suitable

for a particular purpose, provided such is implied by

State law under the circumstances of this sale.

B. WARRANTY ADJUSTMENT:

JABSCO agrees to repair or furnish a replacement

1.

for, but not to remove or install, any product or

component thereof which, within one (1) year from

date of purchase, shall upon test and examination

by JABSCO prove defective within the above

warranty. Receipt verifying purchase date is required

to obtain adjustment.

Buyer shall notify JABSCO of any defect within this

2.

warranty no later than ninety (90) days after the

defect is discovered.

No product will be accepted for return or replacement

3.

without the prior written authorization of JABSCO.

Upon such authorization, and in accordance with

instructions from JABSCO, the product will be

returned to JABSCO, shipping charges prepaid by

Buyer. Products returned to JABSCO will be

addressed as follows:

JABScO

cape Ann Industrial Park

Gloucester, MA 01930

Or to such alternate locations as may be designated on

the product, its container, or this sheet. Repair or

replacement made under this warranty will be shipped

prepaid to Buyer.