M

AINTENANCE

Figure 19: Lifting motor

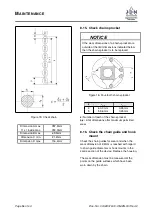

2. Checking vane wear: When the vanes

(7)

are

worn, the engine power is reduced. Replace

the vanes

(7)

and starting aids

(8)

together.

Figure 20: Vane

Vane dimensions after maximum permissible

wear (measured at the thinnest point):

L

H

T

109,1 mm

35,0 mm

5,4 mm

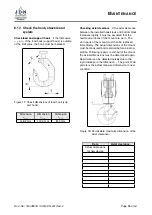

3. Check the braking surfaces of the brake pis-

ton

(5)

and the cover with brake lining

(13)

for

wear and damage: If the braking surfaces are

damaged or worn, the brake piston

(5)

or the

middle part half with the brake lining must be

replaced:

a) The circular wear pattern in the brake

surfaces must not be deeper than

0.02mm:

The extremely low-wear braking material

will not reach the wear limit of 0.02mm

within the design-dependent service life

of the hoist, under intended use. Should

the wear limit be reached prematurely,

the actual compressed air pressure must

be checked with the device switched on

(the brake drags in the event of insuffi-

cient pressure).

4. Engine assembly with additional basic lubrica-

tion of the engine:

a) Provide the braking surface and rotor

bearing (needle bush) of the cover with

the brake pad with a thin layer of high-

performance lubricant.

b) Coat the internal cylinder of the motor

housing lightly with high-performance

grease

c) Coat the entire rotor lightly with high-

performance grease and insert into the

front rotor bearing with the clutch side

first.

Doc.-No.: VA049318-10-OM-EN-0319-64-2

Page

57

of 64