PR_I017/2023-01-23-EN

33

Replacing broken glass

WARNING: NEVER OPERATE STOVE WHEN THE GLASS IS

BROKEN OR CRACKED.

DO NOT SLAP THE DOOR.

NEVER BUILD FIRE NEAR THE GLASS.

NEVER PUT WATER ONTO THE GLASS TO AVOID A

THERMAL SHOCK.

Replace only with a 4mm ceramic glass with the right shape.

DO NOT USE SUBTITUTE.

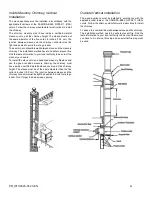

Steps to replace broken glass

1) Loosen partially the screws retaining the four glass

supports.

2) Remove the broken glass and all pieces of broken

glass and clean the door.

3) There is a fiberglass rope for sealing. If not, you need

to install it. Stick the flat fiberglass rope around the

glass without pulling it excessively. A sticking side is

already on the flat rope.

4) Install the new glass and put the lower support first and

gently tighten screw. If screws are tighten too much, it

makes pressure points and it might break the glass

when it gets hot.

5) Install the top support and gently tighten screw.

6) Verify if all the screws are tightened properly.

If you cannot replace glass with the door in place, you may have

to remove the door. To do so, follow the instruction of this

manual.

Fiberglass rope replacement

When it is impossible to adjust the door because of the flattened

fiberglass rope, it is the time to change it. If the rope is damaged,

you also have to replace it.

Use a ½ inches (12.7mm) braided fiberglass rope.

To install the new fiberglass rope, we recommend to detach the

door from the stove. Please see the pertinent section in this

manual.

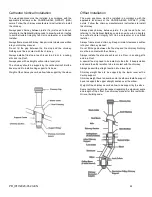

Fiberglass rope preparation

1) Take the end of the fiberglass rope and push fiber

inside.

2) Add little touch of high temperature latex inside the end

of the fiber glass rope to make a clean end.

3) Remove old fiberglass rope and clean the groove.

4) Starting at the lower corner near the hinge put the

fiberglass rope into the grove without giving any

tension to verify the length of the rope.

5) Cut the rope in more than ½ inches and repeat the step

1 and 2.

Fiberglass rope installation

1) Put a high temperature latex inside the clean groove to

glue the fiberglass rope.

2) Starting at the lower corner near the hinge put

fiberglass rope into the groove without giving any

tension

3) Align the two fiberglass rope ends perpendicularly and

put some high temperature latex in between.

4) Let dry the high temperature latex for at least 48 hours.

Put the door back on the hinge and readjust the

tightness.

WHAT TO DO IN CASE OF

CHIMNEY FIRE

CONTACT YOUR LOCAL AUTHORITY TO KNOW WHAT TO

DO IN CASE OF CHIMNEY FIRE. AND BE SURE TO KNOW

PROCEDURE IN CASE OF CHIMNEY FIRE.

1. Close all door, the air inlet and the damper.

2. Water the combustible materials around the stove.

3. Trigger alarm and leave the house, if necessary, and call

the Fire department.

4. Never touch the chimney while is burning.

Do not use the chimney before an inspection or repair

necessary.

.

Summary of Contents for PIONEER

Page 4: ...PR_I017 2023 01 23 EN 4 RATING PLATE...

Page 5: ...PR_I017 2023 01 23 EN 5 APPLIANCE DIMENSION...

Page 6: ...PR_I017 2023 01 23 EN 6...

Page 7: ...PR_I017 2023 01 23 EN 7...

Page 34: ...PR_I017 2023 01 23 EN 34 ANNEX 1 Exploded diagram of door Arc door...

Page 35: ...PR_I017 2023 01 23 EN 35 ANNEX 2 Fans electric wiring diagram...