Check

Explanation/comment

Checked

Check that only necessary fittings

are used.

This helps to minimize friction losses.

Do not connect the piping to the

pump until:

•

The grout for the baseplate or

sub-base becomes hard.

•

The grout for the pit cover be-

comes hard.

•

The hold-down bolts for the

pump and the driver are tight-

ened.

—

Make sure that all the piping joints

and fittings are airtight.

This prevents air from entering the piping system or leaks

that occur during operation.

If the pump handles corrosive fluids,

make sure that the piping allows

you to flush out the liquid before

you remove the pump.

—

This helps to prevent misalignment due to linear expansion

of the piping.

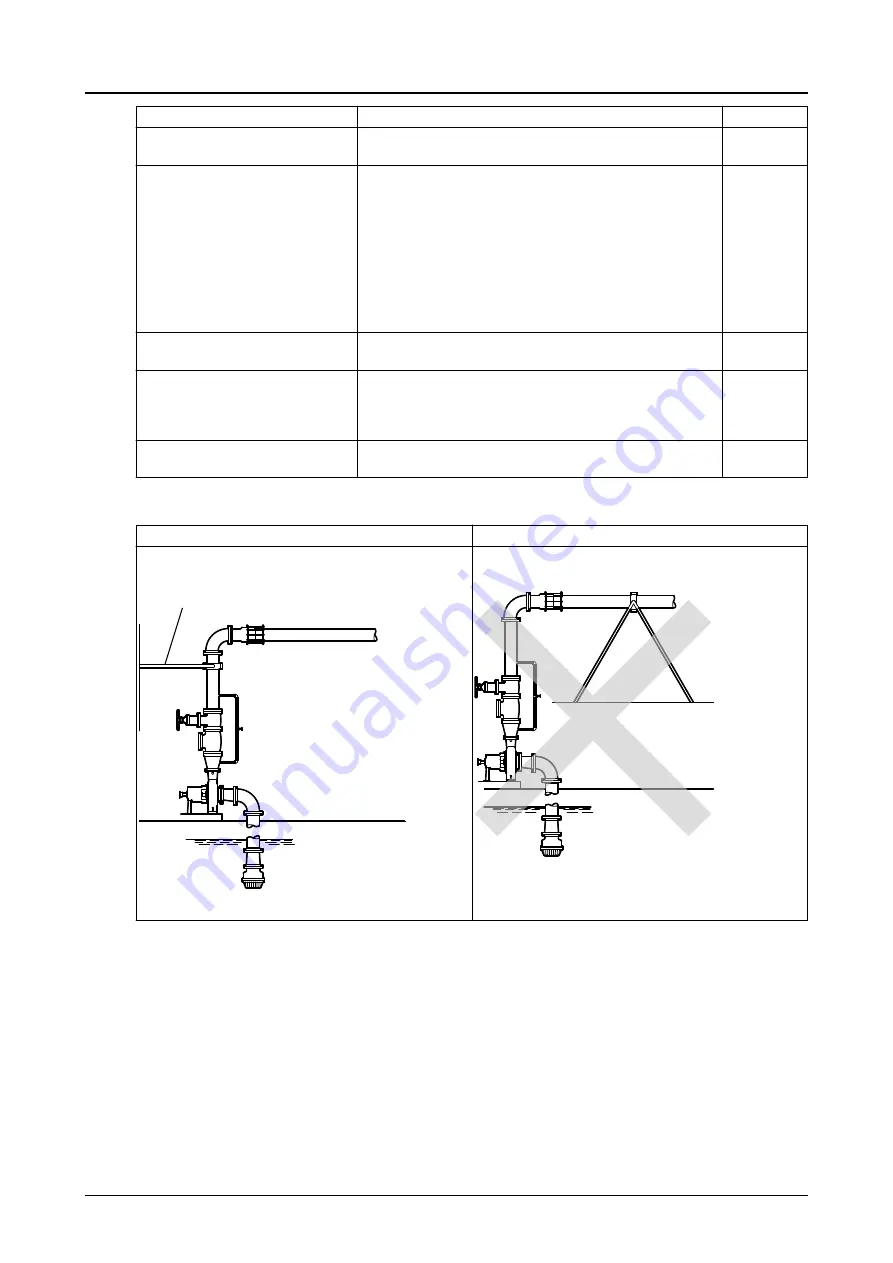

Example: Installation for expansion

Correct

Incorrect

This illustration shows a correct installation for expan-

sion:

1

1.

Expansion loop/joint

This illustration shows an incorrect installation for ex-

pansion:

4.6.2 Permitted nozzle loads and torques at the pump nozzles

Designing suction and discharge piping

The suction and discharge piping must be designed so that a minimum of forces affect the pump. Do

not exceed the force and torque values as shown in the following table. The values are valid for when

the pump is operating or when it is idle.

About the data in the table

The data in the following table has the following characteristics:

•

The data complies with the Europump Recommendation for pumps according to ISO 5199.

•

The data is only valid for static piping loads.

4.6 Piping checklists

Model IC, ICI, ICH, ICIH Installation, Operation, and Maintenance Manual

37